How To Handle Fragile Parts With Robots

Robots were initially used in dull, dirty and dangerous jobs. Today, you can add yet another D to that list: delicate....

How to Handle a High Number of Different Parts Using one Robot

Handling tens or hundreds of different parts with a robot is not a walk in the park. Issues come mainly from tooling...

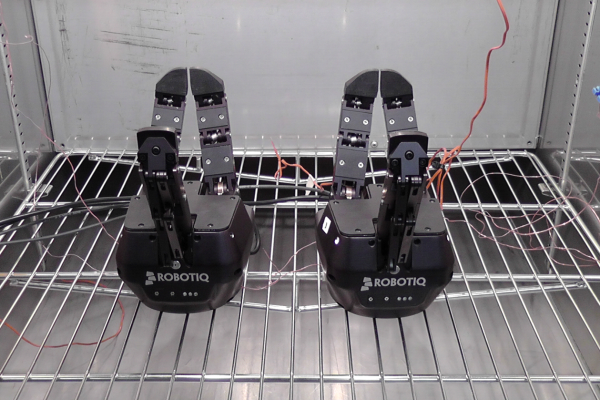

How we Tested the Robotiq Adaptive Gripper

You might look at the Adaptive Gripper and say, "Nice! But is it rugged enough for what we do here?" Robotiq has put great...

Robotic Kitting

When I was young, I was doing hardwood flooring with my brother. I would prepare the pieces of wood on the floor so he could...

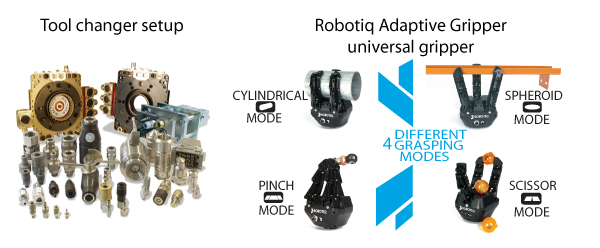

Universal Robotic Gripper Features

Using our demo gripper controlled with an xBox gamepad, we have produced a short video that provides an overview of the ...

Universal Gripper Tooling for Pre-Engineered Robotic Cells

Many integrators tend to standardize building blocks that they can reuse from one project to another. Some of them even turn...

Automate 2011 Robot Roundup

Robotiq Growing Team in the Midwest

Robotiq is pleased to announce expansion in the US with the recent hiring of Susanne Shafer-Denlinger as Midwest Area Sales...

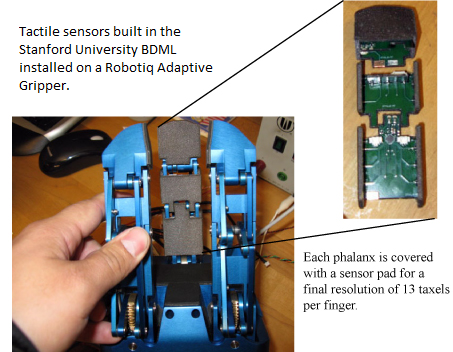

Tactile Sensors for Robotic Gripper

On the Robotiq Adaptive Gripper, you can control the overall force that you apply on a part. You can also detect that a...

Leave a comment