When digital twins meet lean palletizing on the factory floor

CES is often associated with consumer technology and futuristic concepts. At CES 2026, the focus also included something...

Key takeaways from Humanoids Summit Silicon Valley 2025

Data, Deployment, and the Real Path to Physical AI

The Humanoids Summit made one thing very clear: progress in humanoid...

What manufacturers are automating in 2026 (and why)

Walk through a modern plant in 2026 and you’ll notice something important: automation isn’t showing up only in the “high-tech”...

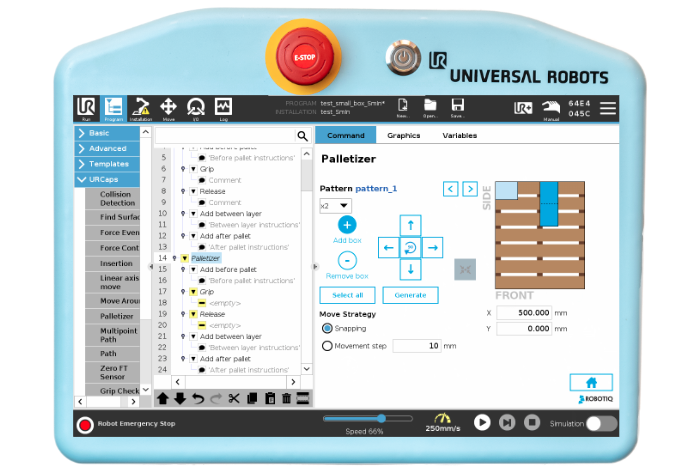

Smarter palletizing, no extra effort: Inside Robotiq’s latest software updates

If you’ve ever spent an afternoon teaching pick positions, you know that what looks simple on paper can quickly become...

What we saw at PACK EXPO 2025: Trends, surprises, and PAL Ready in action

PACK EXPO is always one of the biggest events on the calendar for packaging and automation. This year in Las Vegas was no...

FACHPACK 2025: Smarter end-of-line automation

Every year, FACHPACK transforms Nürnberg into Europe’s hub for packaging automation trends, and 2025 was no exception. From...

Five reasons to visit Robotiq at Pack Expo 2025

Pack Expo Las Vegas is right around the corner, and Robotiq will be there with something big. From Sept. 29 to Oct. 1, you’ll...

Why 100% bonus depreciation speeds up cobot palletizer ROI

For small and medium manufacturers, every dollar matters. Between labor shortages, rising wages, and customer delivery...

Automation, ROI, and the advantages of Lean Robotics

The conversation around automation often starts with cost. Factory leaders ask: “Will this investment actually pay off?” The...

1_2026_Siemens_UR_demo_CES2026.gif)

-1.jpg)

Leave a comment