What manufacturers are automating in 2026 (and why)

Walk through a modern plant in 2026 and you’ll notice something important: automation isn’t showing up only in the “high-tech”...

Inside Cascade Coffee’s playbook for sustainable, scalable automation

When you walk into Cascade Coffee’s facility north of Seattle, you immediately sense two things: the unmistakable smell of...

From risk to resilience: How PAL Ready and PAL Series make palletizing safer for every operator

October is Safe Work Month and a perfect time to rethink end-of-line safety.

For food and beverage manufacturers, where...

What’s the real cost of palletizing automation?

When manufacturers think about automating end-of-line operations, one question almost always comes first: What does a...

Meet PAL Ready and PAL Series: Two clear paths to smarter palletizing

Palletizing may look simple—stack boxes, ship them out—but it’s one of the most critical steps in your logistics chain. With...

Automation, ROI, and the advantages of Lean Robotics

The conversation around automation often starts with cost. Factory leaders ask: “Will this investment actually pay off?” The...

From blank floor space to a running robotic cell in 90 days

When most people think of installing a robotic cell, they imagine a process that takes half a year, maybe more. Endless design...

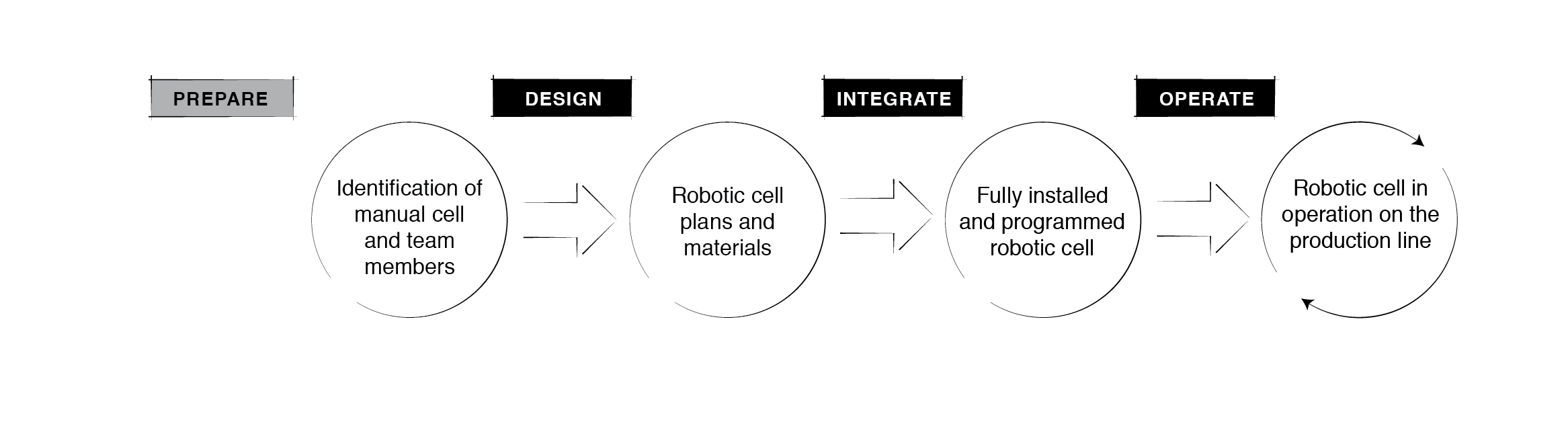

The four principles of Lean Robotics every manufacturer should know

When most people think about automation, they think about the robot.Of course, it’s the shiny, moving part of the equation. But...

Automatica 2025: AI-driven robotics, the humanoid surge, and Robotiq in action

Every two years, Automatica brings together the brightest minds and boldest machines in robotics—and 2025 was no exception....

-2.jpg)

Leave a comment