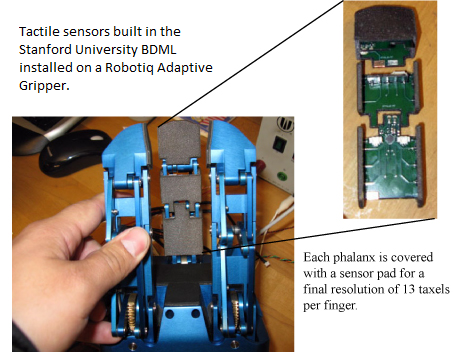

Tactile Sensors for Robotic Gripper

On the Robotiq Adaptive Gripper, you can control the overall force that you apply on a part. You can also detect that a...

How to Simplify Jigs in Robotic Welding Applications

In welding, jigs are used to precisely and firmly position parts while they are welded. The picture below shows such a jig.

Robotic Companies in Quebec

We met with many people in recent months. Here’s a list of the movers and shakers in Quebec robotics.

Plustech Walking Robotic Timberjack

Honda Robotic Exoskeleton

Here’s a video on Honda's new product: a pair of legs supporting a bench you can sit and walk on. The legs support about 15% of...

Self-Adaptive-Robot-Auxiliary-Hand in Popular Science

Popular Science carries an article about SARAH (Self-Adaptive Robot Auxiliary Hand), because it’s part of Dextre’s toolbox....

Leave a comment