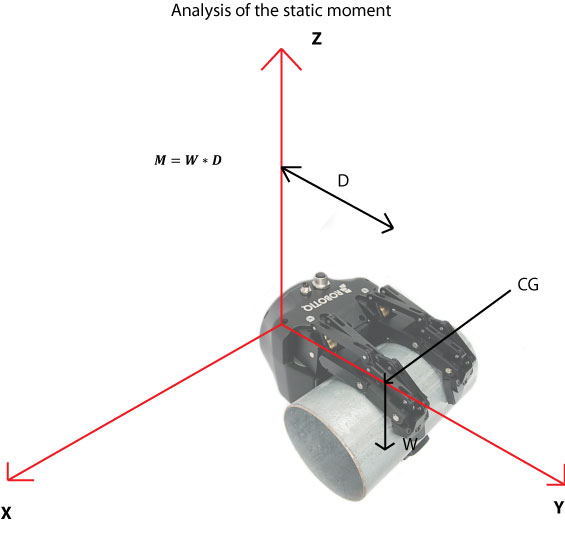

How To Attach An End-Effector To Your Robot

Since there are little to no established standards for attachment interfaces in the robot industry, many things are to be...

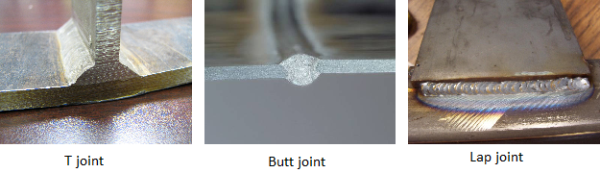

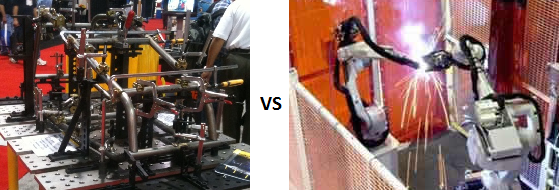

Jig-less Robotic Welding How-to

With their accuracy and adjustability robots are up to face new challenges and execute tasks that were not considered possible...

The Evolution and Advantages of Jig-less Robotic Welding

Are you having trouble finding welders? Are you wondering how you could take advantage of robots to simplify your fixtures...

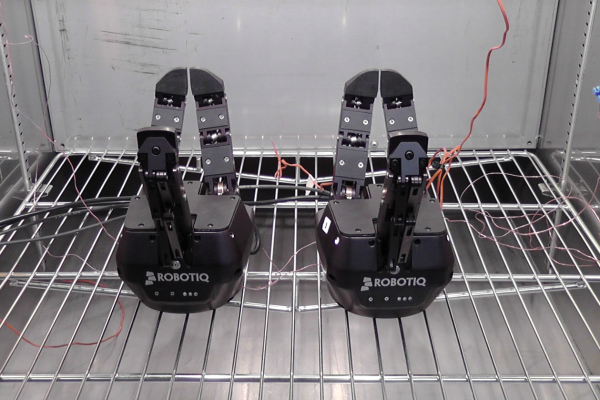

How we Tested the Robotiq Adaptive Gripper

You might look at the Adaptive Gripper and say, "Nice! But is it rugged enough for what we do here?" Robotiq has put great...

Robotic Kitting

When I was young, I was doing hardwood flooring with my brother. I would prepare the pieces of wood on the floor so he could...

The Evolution of the Robotic Teach Pendant

The teach pendant is the most common interface to program an industrial robot. The above picture was taken in the Tribute to...

Universal Gripper Tooling for Pre-Engineered Robotic Cells

Many integrators tend to standardize building blocks that they can reuse from one project to another. Some of them even turn...

Leave a comment