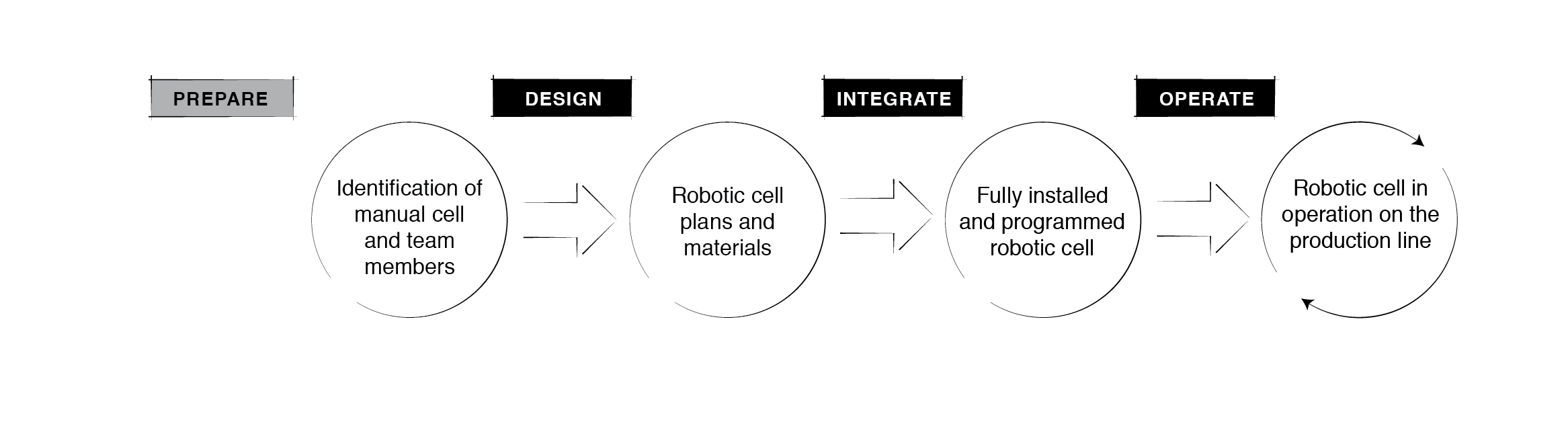

From blank floor space to a running robotic cell in 90 days

When most people think of installing a robotic cell, they imagine a process that takes half a year, maybe more. Endless design...

The four principles of Lean Robotics every manufacturer should know

When most people think about automation, they think about the robot.Of course, it’s the shiny, moving part of the equation. But...

What plant managers need to know before automating

As a plant manager, you’re facing an industrial landscape that’s changing faster than ever. Some challenges—like fluctuating...

Caffè Corsini boosts palletizing efficiency with Robotiq automation

Founded in 1950, Caffè Corsini is an iconic name in Italian coffee, exporting to over 60 countries worldwide. But as demand...

Automatica 2025: AI-driven robotics, the humanoid surge, and Robotiq in action

Every two years, Automatica brings together the brightest minds and boldest machines in robotics—and 2025 was no exception....

The surprising ROI of ergonomics in manufacturing

When manufacturers think about return on investment, they often look at numbers tied to output: faster cycle times, fewer...

Ergonomics 101 for factory managers

If your team stacks boxes all day, ergonomics shouldn’t be an afterthought; it should be the first thing you think about.

...

Debunking the “20-pound rule”: Why weight isn’t the only risk in manual lifting

"Is it under 20 pounds? Then it’s fine to lift." That myth has lived too long on factory floors.In reality, the dangers of...

What is the NIOSH Composite Lifting Index?

Manual palletizing might look simple. But behind every lift is a set of forces, postures, and risks that add up fast,...

Leave a comment