Your Robotiq Configurator just got smarter: Meet PowerPick Multi

If you’ve been using Robotiq’s Palletizing Configurator to plan solutions for yourself or your customers, you know how fast and easy it is to build the perfect system. And now it’s even better as Robotiq's innovation in software and hardware come together.

PowerPick Multi is now live in the Robotiq Configurator

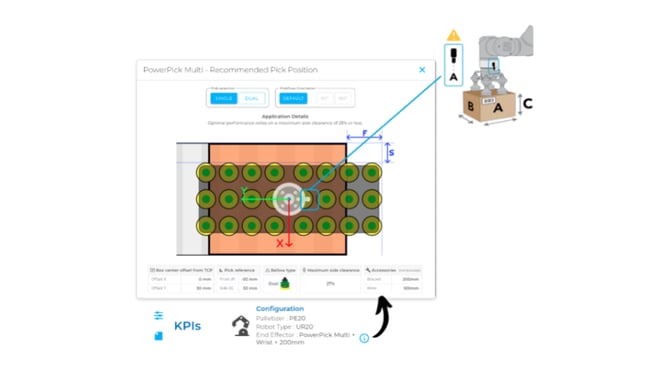

Our newest, most flexible vacuum gripper is now available as a selectable end effector in your configurator workflow, making it easier than ever to spec high-throughput, multi-zone palletizing systems without guesswork or back-and-forth.

.png?width=476&height=242&name=Screenshot%202025-04-15%20at%204.32.15%20PM%20(1).png)

Why PowerPick Multi?

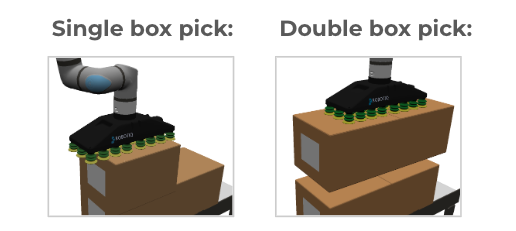

PowerPick Multi is built for factories that need to move more boxes, faster, and smarter. With multi-zone vacuum capabilities and a design optimized for flexibility, it’s your new go-to for:✅ Dual-box picks

✅ High-speed palletizing

✅ Multiple box sizes

✅ Plug-and-play deployment

And now, you can simulate all that functionality right in the Configurator.

What’s new in the Configurator?

Here’s what you’ll notice the next time you plan a solution:

- PowerPick Multi as a selectable gripper

Choose it as your end effector and the configurator will instantly filter for compatible robots—no trial-and-error needed. The Configurator will also propose PowerPick Multi if it is the best option when the end effector is set to "auto". - Single or double box pick

Specify whether your application uses a single-box or dual-box pick. Going with single? The configurator automatically simulates the best pick offset—so you're not stuck manually placing the gripper.

- New information panel

Click the info icon to reveal key gripper setup details, including:

- Offset placement on single-box picks

- Connector position in both single and dual pick modes

- Whether the gripper uses single or double bellow

- Smarter recommendations

The configurator adapts your layout based on your gripper and robot combo—ensuring your simulation is as close to real-world deployment as possible.

A faster way to get to “yes”

Whether you’re a Robotiq partner, integrator, or manufacturer exploring automation, this update gives you more power to visualize your palletizing setup, show ROI faster, and reduce project friction.

PowerPick Multi in the configurator = More throughput + Fewer surprises.

Ready to try it?

👉 Head to the Configurator and build your first simulation with PowerPick Multi today.

Want an expert to walk you through it? Contact us today!

1_2026_Siemens_UR_demo_CES2026.gif)

Leave a comment