What manufacturers are automating in 2026 (and why)

Posted on Dec 16, 2025 in Automation, Palletizing

5 min read time

Walk through a modern plant in 2026 and you’ll notice something important: automation isn’t showing up only in the “high-tech” corners anymore. It’s landing where it creates the fastest, most reliable value — especially in the parts of the factory that used to be left behind because they were too variable, too manual, or too hard to justify.

Across surveys and what we see on real floors, the pattern is clear: manufacturers are prioritizing automation that helps them stabilize output, protect people, and stay flexible under uncertainty. Persistent labor shortages and skills gaps are still the backdrop, so the “why” isn’t mysterious; it’s operational survival and competitive advantage. (Deloitte)

Here’s where automation is concentrating in 2026, and the reasons behind each move.

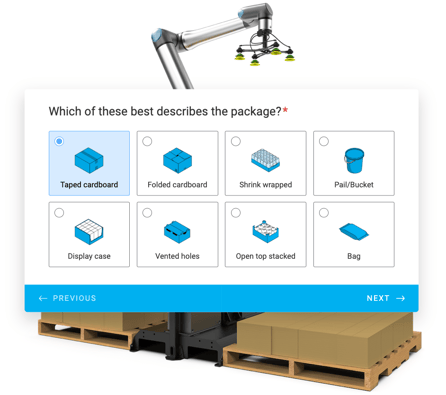

1. End-of-line (palletizing, case packing, warehousing handoff)

What’s getting automated: palletizing, depalletizing, case handling, stretch wrapping, and other end-of-line tasks.

Why in 2026:

- Labor relief where the pain is constant. End-of-line roles are physically demanding and hard to staff consistently. With skilled labor shortages still acute, these stations are prime targets for robotics. (Deloitte)

- Clear ROI and fast time-to-value. These applications have measurable throughput and safety gains, making the business case easier than many upstream processes.

- Flexibility is finally good enough. Plants want automation that can handle SKU churn and seasonal peaks. “Hyper-flexible” manufacturing — systems that can be reconfigured quickly — is a defining shift right now. (The Economic Times)

Robotiq lens: End-of-line is often the first automation step because it’s the cleanest win: stable process, visible impact, and low disruption to upstream production.

2. Intralogistics and material movement

What’s getting automated: AMRs/AGVs for moving pallets, totes, and WIP; automated line feeding; buffer management.

Why in 2026:

- Flow beats speed. Manufacturers are realizing that internal transport bottlenecks quietly kill OEE. Automating movement creates smoother flow without redesigning the whole plant.

- Easier to scale than fixed conveyors. Mobile robotics aligns with the shift to modular, software-defined factories where layouts change more often. (The Economic Times)

Safety + predictability. Automated transport reduces forklift traffic and “last-minute heroics.”

3. Inspection and quality control

What’s getting automated: vision inspection, in-process measurement, AI-assisted defect detection.

Why in 2026:

- Quality is a top digital investment area. Surveys show quality management and AI-enabled inspection sit near the top of manufacturers’ smart-tech spend. (Rockwell Automation)

- AI makes variability manageable. Modern vision + ML handles imperfect real-world variation better than traditional rules-based QC.

Scrap costs are too high to ignore. Catching issues earlier has a compounding effect on yield and scheduling reliability.

4. Machine tending and repetitive production tasks

What’s getting automated: CNC/press tending, loading/unloading, simple pick-and-place, packaging steps, secondary ops.

Why in 2026:

- High repeatability = quick wins. These tasks are stable, easy to standardize, and ideal for cobots and compact cells.

- Aging skilled trades gap. The shortage isn’t just general labor; it’s experienced operators and technicians. Automation helps keep machines running even when staffing is thin. (Deloitte)

Plants are scaling beyond pilots. Many manufacturers are moving from experiments to deployments that deliver measurable output. (Rockwell Automation)

5. Maintenance and uptime (predictive + autonomous)

What’s getting automated: AI-driven predictive maintenance, automated alerts, condition monitoring, spare-parts planning.

Why in 2026:

- Downtime is the universal enemy. Predictive maintenance keeps legacy equipment viable while plants modernize gradually.

AI maturity is rising fast. Manufacturers are broadly investing in AI/ML and increasingly using it to anticipate failures and schedule maintenance intelligently. (NIST)

6. Planning, scheduling, and supply-chain decisions

What’s getting automated: AI-assisted production scheduling, automated quoting, dynamic inventory decisions.

Why in 2026:

- Uncertainty demands adaptability. Tariffs, demand swings, supplier volatility — plants need schedules that can re-optimize quickly. (Reuters)

- AI is moving upstream. IDC predicts a large share of manufacturers will upgrade scheduling with AI to enable more autonomous operations. (IDC Blog)

The common thread: "factory-ready, not science-fair"

Across all these areas, one theme stands out:

Manufacturers are automating what can be deployed quickly, owned by the team, and adapted to real floor conditions.

That’s why we see:

- modular cells over bespoke megaprojects,

- incremental automation over “rip and replace,”

- and systems that operators can run confidently without a PhD.

It’s also why workforce training and adoption are becoming the make-or-break factor. Even the best tech stalls without people who can own it. (Deloitte)

What this means for your 2026 roadmap

If you’re planning your next automation step, take a cue from what’s winning across the industry:

- Start where the process is stable and the pain is obvious (end-of-line is the classic example).

- Prioritize time-to-value over perfect long-range specs.

- Design for variability, not the ideal drawing.

- Build operator ownership early so the system scales instead of stalling.

In 2026, automation isn’t about chasing the most futuristic factory.

It’s about building a Lean, flexible, resilient one, one step at a time.

If you want to see whether palletizing automation makes sense for your facility, start with the Palletizing Fit Tool — a quick, interactive way to see if Lean Palletizing is the right match for your line.

1_2026_Siemens_UR_demo_CES2026.gif)

Leave a comment