Manufacturing Industry Forecast: Growth and Flexibility Is in the Air

Posted on Dec 07, 2012 1:38 PM. 3 min read time

One of the top subjects at FABTECH a few weeks ago was about how well the manufacturing industry was coming back from the 2008 economic crisis. A good example of this was the record attendance for the show with the first day at 16,000 people (the biggest crowd ever for a single day at FABTECH) and the third largest FABTECH show in terms of both floor space and number of exhibitors. Economists and companies attending the show were also enthusiastic concerning investments and production in the manufacturing industry. Not to set new sales or investment records, but to have a reliable and steady growth.

was coming back from the 2008 economic crisis. A good example of this was the record attendance for the show with the first day at 16,000 people (the biggest crowd ever for a single day at FABTECH) and the third largest FABTECH show in terms of both floor space and number of exhibitors. Economists and companies attending the show were also enthusiastic concerning investments and production in the manufacturing industry. Not to set new sales or investment records, but to have a reliable and steady growth.

Here are some points from the 2013 Capital Spending Forecast that are also supporting the mood of the industry.

- With a $2.2 billion spending projection for 2013, the industry is just shy of the spending that was projected before the recession.

- Even if manufacturing growth has slowed lately after 34 straight months of expansion, the experts predict that this growth will continue to be higher than for the general economy in 2012.

- The top 3 motives for investment are to 1) Increase production capacity (26 %), 2) Reduce costs (25.6%) and 3) Get machines and/or processes to improve production flexibility (13%)

- In 2013, business spending on capital equipment is expected to increase (47.3%) or remain the same (40.5%).

- 61.4% of the capital equipment budget will be spent on new equipment vs 27.8% on used equipment.

- Welding and Laser cutting machines will be the most popular type of equipment to be bought at $326,766,235 and $224,836,759 respectively.

- 44.4% of all dollars to be invest in manufacturing will be in the North Central Area (Michigan, Ohio, Wisconsin, Illinois and Indiana)

- Plants that will spend more money will be the those with 500-999 employees (an increase of $1,751,998) and companies having more than 1,000 employees will reduce their investments by 7.6% to $2,689,286.

From these facts, it is interesting to note that investment in manufacturing is coming back and those investments are motivated by process improvements. Also, the need for flexibility is more and more a criteria for new projects. The fact that larger businesses are tending to slow down their investment might worry some people in the industry. But most people underline the fact that larger companies tend to outsource some of their production, particularly related to low-volume products. Then they concentrate on what they do best and rely on their top performer fabricators for their flexibility and ability to provide quick turn around. This could explain why the flexibility criteria is one of the top three reasons that motivate investment and why the total investment for companies of 500-999 employees will be so important in 2013.

Production flexibity is in the air with robotics too

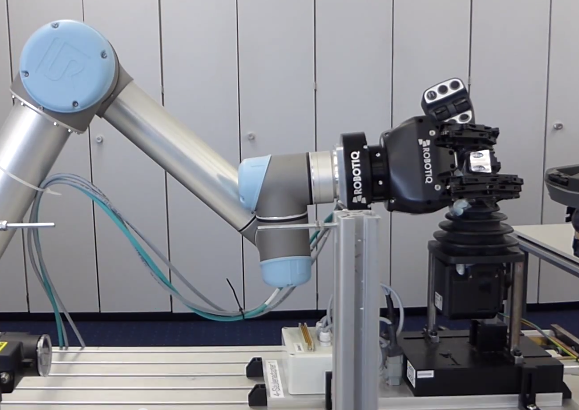

On the robot side, we can say that flexibility is also more and more in the air. With the Baxter robot from Rethink Robotics released at FABTECH and the North American release of Universal Robot at Automate 2013 in January, manufacturing companies will have access to industrial automation flexibility at low-cost. This new generation of industrial robots will give flexibility to manufacturers and make their use more userfriendly. For those who are curious about Baxter, here is the video that I took at FABTECH.

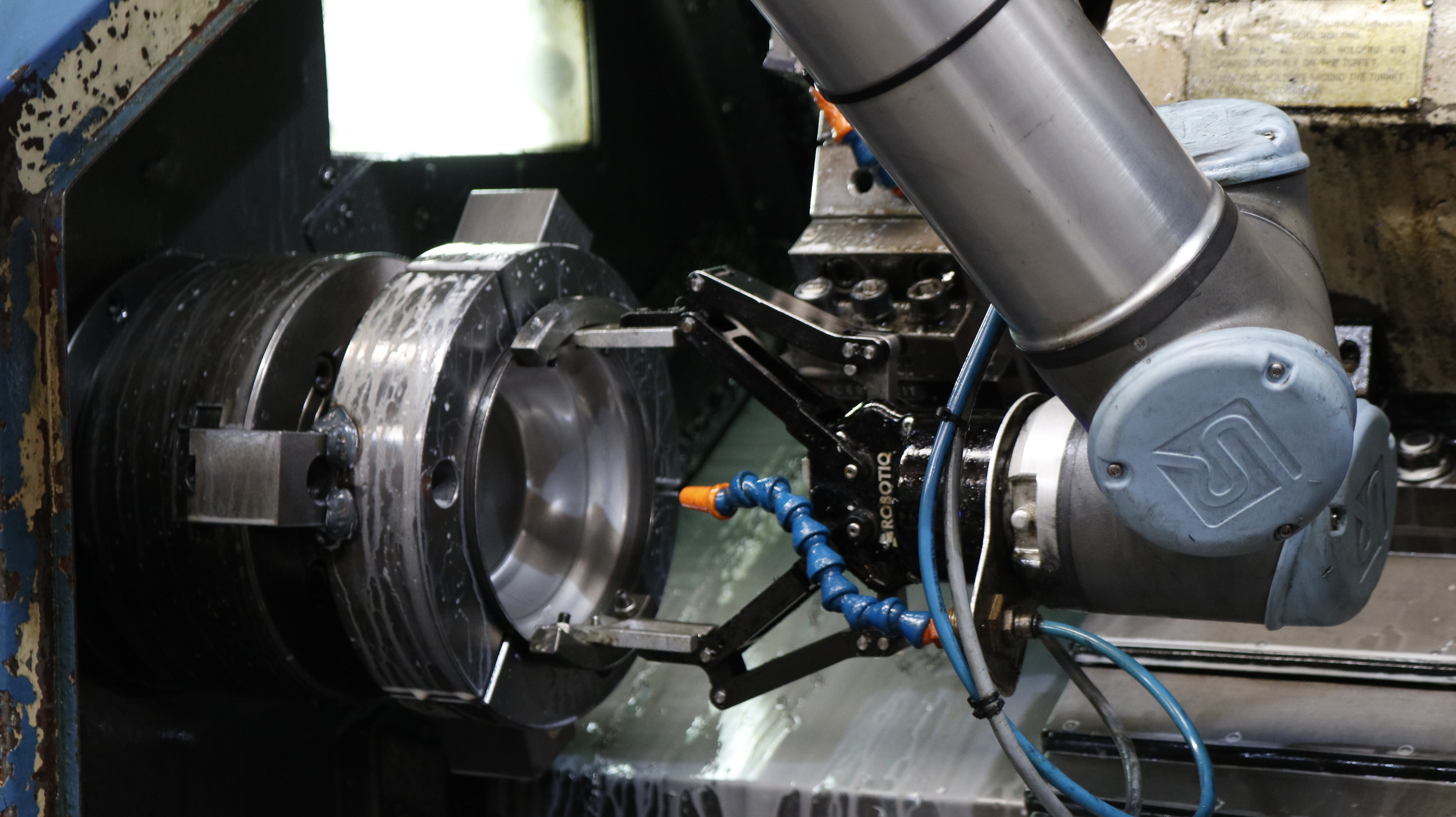

Our Adaptive Robot Grippers are also part of this trend by providing flexible tools to smaller companies thereby allowing the handling of a wide variety of parts with a single gripper. They are also a perfect fit with Universal Robot (read our blog about that) when it is time to deal with high-mix, low-volume production or a production process that changes regularly.

Maybe we don't know if these predictions will be true for 2013, but one thing we do know for sure is that the competitiveness of North American manufacturing industries will require more and more process flexibilility.

Leave a comment