Why Cobots Are NOT The Challenge

Posted on Apr 08, 2019 6:31 PM. 4 min read time

Robotiq's Technical Support Director Etienne Samson explored the principles of Lean Robotics and shared his essential tips for a successful cobot deployment @Automate 2019 this afternoon...

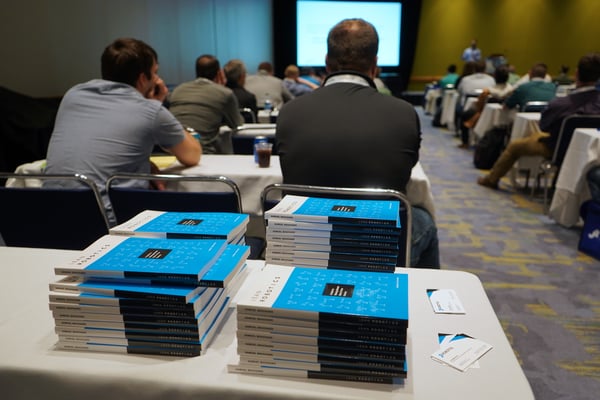

There was a full house for Etienne Samson's presentation at Automate today, with more than 100 attendees curious to learn more about the ways in which Lean Robotics principles can help manufacturers design, integrate and operate collaborative robot cells in a timely and cost-effective manner.

Etienne Samson explores Lean Robotics topics at Automate 2019. Credit: Robotiq

Here are some of the highlights of what turned out to be a really popular and interesting presentation...

Why cobots are NOT the challenge

Cobot manufacturers have done a good job producing easy-to-use products, Etienne explained: "You order your cobot. It arrives in two weeks. It's easy to deploy and program. You can plug it into the wall and program a simple pick & place task in 15 minutes."

The challenge is not the cobot then, but there are challenges all around the cobot.

This includes application design, interfaces with other machines, programming and part feeding. It means performing a risk assessment, working out which sensors you'll need for your applications, and handling upgrades.

So, how can you successfully manage these challenges and the complexity they create? We're glad you asked!

Technical Support Director Etienne Samson shares his tips for a successful cobot deployment. Credit: Robotiq

Etienne's Essential Tips

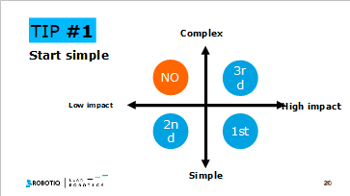

Start Simple. Consider the operational impact (horizontal axis) and complexity (vertical axis) of your deployment. Frame the problem in the context of the whole company, not only manufacturing operations tasks. If you have to choose between simple+low impact VS complex+high impact, go with the simple one. "Nail it. Learn by doing. Then scale it to more complex tasks."

Keep it simple. "If you want to automate a CNC machine tending and you let your imagination go, you will probably add a cleaning station, maybe a packaging step, might as well try to do assembly or inspection too. Next thing you know, nobody's smiling anymore, you’re over budget, over schedule. Don’t let this happen to your first cobot application deployment!"

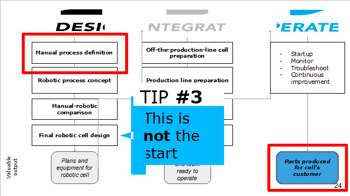

Know where to start. Your project starting point should be the mannual process that you want to automate. Before defining the technical solution, take the time to document and understand the manual process. This investment will pay dividends later in the project. Consider your end goal and the business metrics that you're trying to improve.

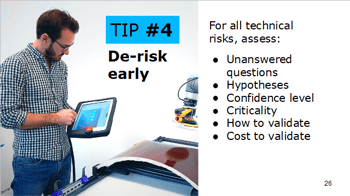

De-risk early. Don't be afraid to make the small investment of time and effort it takes to experiment with your design and remove risks without doing complete integration.

This will build confidence and know how, and help you to better gauge the technical complexity before commiting.

Standardize your toolbox. "What’s really expensive in robot deployment is less the cost of the material but rather the custom engineering, or the time your robot is not producing."

Training. "Factories used to compete for manual labor with factory down the street. Now they compete for robotics talent with the Googles, Ubers and Amazons of this world." The new manufacturing environment requires employees with new skill sets, including robotics and mnaufacturing know-how.

Monitor. "It's simply impossible to improve if you do not track your performance. When you have reached your KPI goals and performance is stable, it's time to either add a task to your robot or move on to the next project."

****

We thought we had brought enough copies of the Lean Robotics book (written by Robotiq's co-founder and CEO, Samuel Bouchard) along...

Credit: Robotiq

..but it was so popular that we ran out in minutes!

Going, going, gone... like a copy of Lean Robotics at Automate 2019. Credit: Robotiq

(If you missed out on a copy of the Lean Robotics book at the presentation, visit Booth #7165 and we'll sort one out for you.)

To learn more about Lean Robotics and how it can enable speedy, cost-effective cobot cell deployments, be sure to visit the Lean Robotics website.

****

Next: Join us for our roundup of Day 1 at Automate 2019!

Leave a comment