Cobots vs. Covid Initiative: Start Simple

by Samuel Bouchard.

Last updated on Nov 23, 2021 11:31 AM

Posted on Apr 06, 2020 4:10 PM. 3 min read time

Posted on Apr 06, 2020 4:10 PM. 3 min read time

- This article is the second of a 7-part series supporting our Cobots vs. Covid initiative:

If you are a manufacturer ramping up production of mission-critical goods, Robotiq wants to help you deploy a cobot application in two weeks. - Watch our 23-min video explaining the program.

- Ready to take action? Contact us now.

Key to Success #1: Start Simple

Why Starting Simple is Essential

- Starting simple means identifying a job that will be simple for the robot to do and simple for you to deploy.

- Complexity is the enemy of execution. And we need to execute fast to be successful. Keep in mind that working remotely in a high-pressure environment already involves complexity. By starting simple, we’re doing ourselves a huge favor.

- Starting simple will have positive repercussions throughout the project: making design, integration, training, and troubleshooting faster and easier.

What Counts as “Simple”?

Simple for the Robot

- Think of robots as near-perfect motion repeating machines. They’re way better than humans at predictable, repeatable tasks.

- Remember, though, that all the sensory motor skills you take for granted (like coordinating your sense of sight and touch with your hand movements) are far more difficult for robots.

- Also keep in mind that this is not linear: simple things can be very simple, while complex things can be very complex.

- In other words, a manual task that is easy for you is not necessarily easy for a robot.

Here’s a quick way to test if your task is simple enough for a robot:

- Could you do it:

- One-handed?

- Wearing a mitten?

- And blindfolded?

- Don’t use an “ideal scenario”—use a real case on the production line, considering how parts are presented and dropped off, and whether humans are doing any non-obvious tasks like visual inspection or tweaking parts in the process.

- If you can perform the task with these limitations, that’s a great start. Obviously we’ll dig deeper into this with you as we move along, but this rough guide can help you do the first filter.

Simple to Deploy

- In the previous article, we explained some criteria for a successful project. Three of them relate to simplicity on your end:

- Do you have an automation team in place of at least two people, who will be 100% dedicated to the project?

- Do you have prior experience with robots?

- Can you share data remotely with Robotiq (WiFi, cell network)?

- If so, and if we choose a simple job for the robot, we will be able to support you remotely to get it done.

Simple Cobot Jobs

These are some of the simplest jobs for a robot:

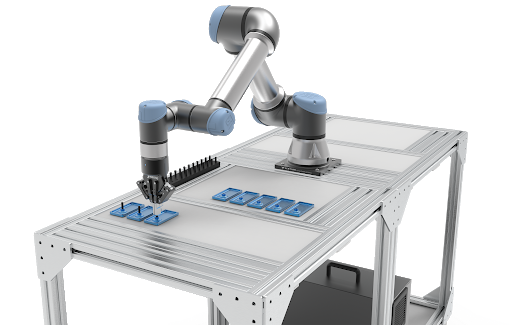

- Pick and place. Transferring parts from one place to another.

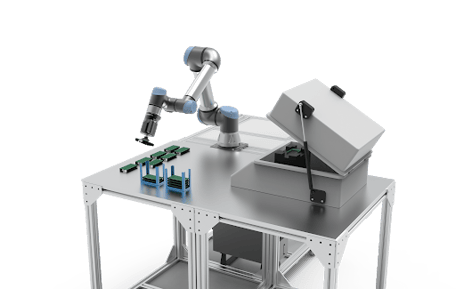

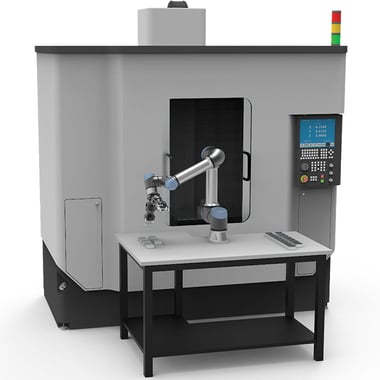

- Machine tending. Loading and unloading parts from a machine (pictured below with a testing machine and CNC machine).

- Packaging. Placing products in packages.

How We Will Work as a Team to Start Simple

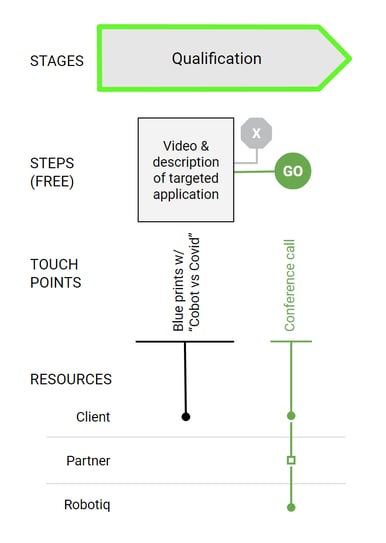

One of our Integration Coaches will work with you to qualify the application within 48 hours of initial submission.

- You can submit written instructions for your target application here. Your application will remain confidential.

- We will then organize a video call on the factory floor.

Want to take action?

Upcoming article: Key #2 - Keep it Simple

Leave a comment