What's the Difference Between Automation and Robotics?

Automation and robotics are two different, but closely related concepts. Both are part of the daily life of companies in several industries, helping them be more profitable by streamlining and optimizing internal processes.

Automation refers to a broad concept that involves using technology to perform tasks automatically without direct human intervention.

Robotics is a mix of different sciences like engineering and computer science used to design, build, and operate robots. Robots are programmable machines that can complete tasks autonomously or semi-autonomously.

In this article, we highlight the key differences between automation and robotics. Then, we go into more detail about each and conclude with future trends.

Key Differences and Commonalities

Automation refers to the process of automating tasks using technology, which may or may not include robots.

Examples of automation technology that are not robotics include the programming of computer systems, specialized software for the control of industrial processes, or the implementation of building control systems like automated lighting or HVAC controls.

Robotics focuses on the design, construction and programming of robots to perform specific tasks.

Robots can be automated, but they don’t have to be. For example, some robots require a person to control them, like remote-controlled drones.

Automated robots examples are everywhere, from those designed to assemble components on a production line to ones that vacuum floors or mow lawns.

Robotics and automation technology can be used together or separately depending on the objective and needs of a project or company. As we will see, both fields provide similar benefits to physical processes, business processes, and to the competitiveness of a company.

What Is Automation?

Automation means using computer software, machines, or other technology to carry out a task that would otherwise be done by a human worker. It thereby frees up that worker’s time to concentrate on more complex and strategic activities.

There are many types of automation, ranging from the fully mechanical to the fully virtual, and from the very simple to the extremely complex.

Types of Automation

Let’s take a look at the two main types of automation: software automation and industrial automation.

Software automation is used to perform tasks normally done by people on computers. There are numerous branches, types, and trends of software automation: test automation, robotic process automation (RPA), Intelligent Automation, and more.

Software automation includes robotic process automation where robots handle repetitive digital tasks, and intelligent process automation which integrates with AI for smarter automation. Automating office tasks can contribute to improving business processes.

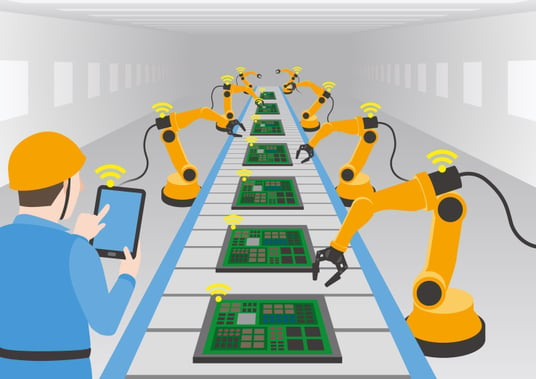

Industrial automation involves physical processes that are automated with physical robots and special control systems. It can involve single machines doing specific tasks or a fully automated production line. Industrial automation is an increasingly important aspect of optimizing production and manufacturing processes. There are different types of industrial automation:

- Fixed Automation, also known as rigid automation, involves the implementation of systems designed to carry out specific tasks in a repetitive manner and in a single location. A common example of fixed automation is an assembly line in the automotive industry, where robotic arms perform assembly tasks in sequence.

- Programmable Automation allows for agility in production as software is reprogrammed or reconfigured to adapt to different products or processes. Unlike fixed automation, programmable automation allows a robot to be reprogrammed to change the sequence of operations or production parameters as necessary.

- Flexible Automation takes it one step further by enabling rapid adaptation of production systems to meet evolving market demand. An example of flexible automation would be a factory creating electronic components, where production cells adapt to changes in product design or demand.

- Intelligent Automation, also referred to as cognitive automation or industry 4.0, relies on advanced technologies such as artificial intelligence, machine learning and data analytics to optimize industrial processes. Intelligent automation allows for autonomous decision-making and real-time adaptation to changes in the production environment. An intelligent automation example would be bots using sensors and data analysis to predict and prevent machinery failures.

Automation Benefits

Automation is all about using technology to make tasks easier and more efficient. It involves using machines or computer software to do jobs that humans usually do. By delegating tasks normally performed by humans, automation addresses several common issues:

- Labor shortage: It is increasingly difficult to find, train, and keep workers who perform repetitive tasks. Having automation take over these jobs not only helps lower the number of workers needed but also allows workers to specialize in more interesting and strategic activities, which is likely to encourage them to stay with the company in the longer term.

- Safety: Repetitive tasks present health and safety issues as they expose workers to injury. Automation can prevent these safety hazards.

- Efficiency: Unlike humans, machines can run continuously without fatiguing while remaining precise. This increases output and reduces error.

- Competitive edge: Companies that implement automated systems gain a competitive advantage by improving efficiency, lowering costs, and offering higher quality products.

At its core, automation is about enhancing efficiency and precision in the digital as well as physical world.

.

What is Robotics?

In most cases, robotics is a branch within the broader field of automation, focusing specifically on physical robots. It incorporates multiple disciplines to design, build, program and use robotic machines. These robots can transform the way we work.

Generally, the goal of robotics is to automate tasks or processes.

Types of Robots

Let’s take a look at three types of robots: industrial robots, service robots, and humanoid robots.

- Industrial robots are used in factories and warehouses to automate tasks like welding, assembly, and material handling. They are designed for precision, speed, and repeatability and are often stationary. Industrial robots are versatile and can be reprogrammed to perform various tasks. They are most often used in printing, packaging, welding, machine tending, material handling, and metalwork.

- Service robots are used in homes, hospitals, hotels, offices, airports, museums, and shopping malls to perform tasks like cleaning, greeting visitors, or making deliveries. They are made to interact with humans and are usually more affordable and less complex than industrial robots. Examples include a robot vacuum cleaner or lawn mower or an interactive robot greeter at a doctor’s office.

- Humanoid robots look like human beings. They are programmed to interact with the environment in ways that a human might and can have facial features to mimic emotion. Sophia is an example of a humanoid robot. Sophia is embedded with neural networks and artificial intelligence to recognize human faces and understand their gestures and emotions, and respond appropriately.

Robotics Benefits

Robotics have myriad benefits including, but not limited to:

- Improved accuracy and consistency - Robotic systems are precise, making their output both accurate and consistent. They virtually eliminate human error.

- Improved product quality - Robots are not affected by fatigue or distraction due to repetitive tasks the way that humans are. This improves quality assurance.

- More efficiency and output - Unlike human workers, robots do not need to take breaks or have set work shifts, so production can operate 24/7. Better quality assurance means fewer wasted products and greater yield.

- Job creation and employee retention - Contrary to popular belief, robots are not eliminating jobs but creating new ones! Now that manual and repetitive tasks can be delegated to machines, humans can rise to roles where the skills can be better used and developed. For example, more software developers, and programmers are needed to service and maintain robots, and new professionals will be required to keep the automated production line running smoothly. This career progression often leads to increased employee satisfaction and retention.

- Increased workplace safety - Working on a production line can be particularly dangerous for human workers. Allowing robots to take on strenuous, repetitive tasks takes humans out of harm’s way.

Future Trends in Automation and Robotics

So, what does the future hold for automation and robotics?

As both fields continue to revolutionize industries by bringing more precision, efficiency, and safety to various processes, automation and robotics will transform existing industries and also act as a catalyst for new sectors to emerge.

Here are our predictions for upcoming trends in automation and robotics:

- Integration of AI - Continuous advancements in AI and machine learning are making automation systems more intelligent and adaptive. This means that future robots will go beyond just performing repetitive tasks; they will also be capable of making complex decisions, analyzing real-time data, and learning from their surroundings, boosting productivity and minimizing human error.

- Collaborative robots (Cobots) - Collaborative robots, also known as cobots, are designed to work alongside human employees without safety barriers. They are designed with safety and flexibility in mind, allowing them to perform various simple or complex tasks while remaining straightforward enough for non-experts to program and handle. We will see an increase in their implementation across industries.

- Expansion in non-industrial sectors - The versatility of robotics and automation allows for their application across a variety of sectors, including healthcare, agriculture, services, and more. Widespread adoption will lead to uniform growth and innovation, contributing to economic stability and job creation in new areas outside of repetitive tasks.

Have questions about the differences between types of automation? Ask us in the comments below or join the discussion on LinkedIn or Facebook.

Leave a comment