The Future of Robotic Welding

Posted on Jun 20, 2011 10:33 PM. 4 min read time

A few weeks ago, I had the opportunity to attend the 2011 AWS Robotic Welding Conference. The closing talk was given by Chris Anderson, welding leader at Motoman. With great humor, Chris presented a case study he was supposed to present at the exact same event in 1987. I had a lot of fun listening to him, always enjoying that kind of historical talk about robotics and technology.

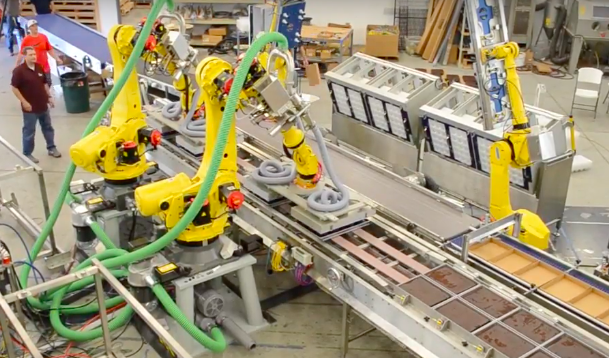

His talk was inspiring. Back then, you had to be a visionary to learn computers at a time when they were using punch cards. I am impressed by the trailblazing that this generation of roboticists did. As you can see in the above images taken from his presentation, they already had developed many technologies back in the 80's.

His concluding remarks were quite disappointing though. When Chris was asked "what is the future of robotic welding?" - I would have expected an exciting conclusion on some crazy promising ideas. Instead, the audience got a few incremental points on current welding approaches and some wireless teach pendant bashing. It left me thinking. Guys, maybe it's time to dream about the perfect robotic welder and have a little fun.

I have to confess, I don't have a welding background. However, this gives me the advantage of looking at the application with fresh eyes. There are things that strike me when I look at robotic welding that make me think... "There has to be a better way."

Programming Robotic Welding

Robotic programming is not an issue that only relates to welding. A recent post on the future of robotic programming led to a heated discussion on Linkedin. The current big thing in robotic welding programming is off-line programming, which indeed makes a lot of sense.

Offline programming is great because changeover times are greatly reduced. Still, it requires a lot of learning from welding engineers to become proficient with the software and time to program. From my standpoint, there is still a lot of room to simplify robotic welding programming so skilled welders with very little robotics background can program a cell.

Couldn't we have self-programming cells that do 80% of the programming from CADs or 3D scans? Some examples already exist out there. See for instance what AGT has done for structural steel welding and Inropa has done for painting.

And once 80% of the programming is automated, could we not do touchups by taking the robot by the torch directly in teaching mode, without the hassle of jogging with the pendant?

Fixtures for Robotic Welding

Fixtures are ugly, custom made pieces of art. You don't want art on your shop floor because you then rely on artists that are getting more and more scarce in the market every day. You want processes that are repeatable and that you can teach and transfer to people easily. Any welding job shop will tell you, jigs are a pain. Not only are they costly, their creation and lack of flexibility creates bottlenecks in the realization of their contracts.

Jigless welding is already out there. At Robotiq, we believe we can help simplify jigs by using our Adaptive Gripper and a vision system to position different parts accurately.

Before and After Robotics Welding

At the same conference, Lance Guymon from Wolf Robotics argued that robotic welding is now quite mature and that we need to look before and after the welding in the chain to improve the overall efficiency. Many interesting points were touched during his talk, including logistics and quality control.

SEE ALL PRESENTATIONS FROM THE CONFERENCE HERE

How Far From the Intelligent Robotic Welder?

At the conference, the President and founder of Servo-Robot Jean-Paul Boillot received an award from the AWS for his contribution to the field. Mr. Boillot could not attend the conference to receive the award. His US President read his thanks to the crowd. Being the son of a welder, Boillot started to dream about the intelligent robotic welder a long time ago. In the text, you could feel his disappointment about the fact that his vision has not fullly turned into reality. One reason he offers for this is the lack of cooperation amongst different players... This application deja vu reminds me of another article written about the current stagnation of industrial robots.

Leave a comment