Construction Robots

Posted on Feb 09, 2007 8:24 AM. 3 min read time

Say you have an inkjet printer. Now, instead of applying ink to paper, you’re applying a plastic filament of a certain width. If you go over it several times, you will create a 3D object. You now have a quick prototyping machine like those offered by Stratasys that we often use at Robotiq for prototyping. Now let’s push the idea a little further. Use concrete instead of plastic and increase the scale by a factor of 100 or 1000. You will have a robot like in the illustration, capable of constructing buildings, layer by layer.

Two separate groups are trying to achieve just that, and soon. One is American (see their site for animations) and the other is English. As you can read in this Times Online article, the American group is developing a 1½ million dollar US system that can build a single-family home in 24 hours. This system should be ready within a year. The English system, ready in four or five years, will be able to build a house in about a week. However, it will be able to directly construct the plumbing, air conditioning, and the electrical and communication networks.

Both approaches are very similar and confer the same advantages: building irregular shapes, rapid construction, automatic, inexpensive, tiny environmental impact. We’re told that this could even be a promising avenue for building colonies on the moon or Mars. But, keeping our feet on terra firma for the time being, I imagine they’ll do like the astronauts and test their wares somewhere around Sudbury. A question I’m asking is how this type of construction might be adapted to harsh climates like ours. Might we resort to the old Soviet (or even the first Quebec colonists) approach to construction: forget insulation, just build thick walls?

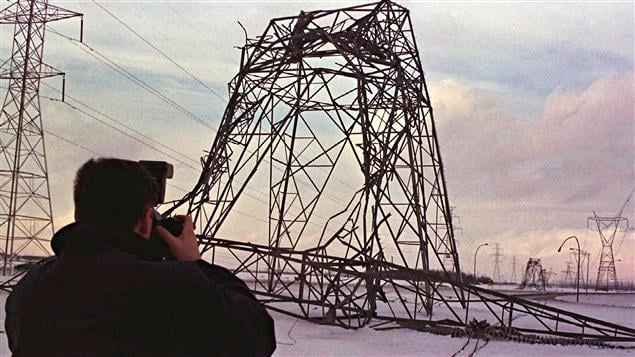

I learned of this concept last fall at an ASME conference. Paul Bosscher presented his work on cable-driven robots that could used to lay concrete (see his publication). His presentation piqued my curiosity, as I also work on cable-driven robots. His research was motivated by the fact that the current design of the Cartesian robot in the picture quickly becomes impracticable. To erect large buildings, we must first erect the robot, which can be just as complicated and therefore pointless. His idea is therefore to build a cage around the volume the building will occupy and have the head shift inside under the control of many cables connected to the cage.

In my opinion, this construction method still needs many years of development before it becomes widespread. However, if it reaches its potential, it can radically change the face of architecture. As the leader of the English team, Dr. Rupert Soar, did, architects with this technology might travel to Namibia to gain inspiration from termite mounds, which are far ahead of us in this area.

Leave a comment