Practical Universal Robots' Demo

Posted on Jul 20, 2015 2:02 PM. 2 min read time

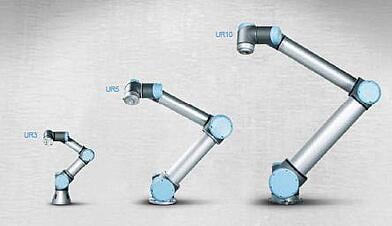

Michigan based Axis Systems has been developing interesting demonstration videos using Universal Robots. These demos can give you a better idea of what can be done using their robots.

The first demo of a depalletizing routine is viewed from the gripper’s perspective. It is interesting to view the video from the end-of-arm tool’s perspective, since it is something that we rarely see. Most palletizing applications are done with flat surfaces and can be done using cartesian coordinates. However, in this case, Axis has tilted the surface to makes it more complex to program (not so tough though). The programming method uses the pallet mode embedded in the Universal Robots’ controller. This mode allows you to set a starting position (first part), then enter the distance between the previous part and the next part using the X and Y axes, finally entering the number of rows and columns of pallets the robot needs manipulate in order to execute the routine autonomously. The pallet feature can be used in applications such as machine tending or assembly tasks where several like parts have to be processed.

You should also notice the small distance between the screws and how the Robotiq 2-Finger 85 Gripper can still grasp them. This is due to its programmable stroke. The Gripper can be opened only slightly to allow for a better clearance of the other objects on the pallet. Take a look at the video to have a better understanding.

The second demo is more about the safety UR features, that can be integrated into the robot logic using the new CB3 controller. In fact, when the robot is paired with a proximity sensor, it can monitor its surrounding and determine the right speed/acceleration settings for the situation. In this particular case, 3 zones have been set. The first zone (green light) is when the worker is out of the robot working zone. This means the robot can go full speed and does not pose a risk of harming a human. The second zone (yellow light) is when the worker has entered the ''Reduce Speed Zone'' where the robot will lower its speed because the worker can potentially be harmed by the robot motion. The third zone (red light) is called the ''Safeguard Stop Zone'' where the robot will stop to avoid any kind of collision since the worker is very close to the robot.

Even though UR robot arms have built-in sensors to detect abnormal force, it is still safer to avoid impact altogether than detecting it through contact, right? Well that is the philosophy of this demo.

If these examples have given you some ideas for your next robotic cell, well you now know which door to knock at: Axis Systems. They are specialized in many types of automation, but they have a certain expertise in UR robot integration. The fact that they also use and distribute our Grippers. If you want to get tricks and tips on how to program your Universal Robots, follow the link below.

Leave a comment