Standard vs. Customized The Great Debate

Posted on Aug 02, 2023 8:35 AM. 5 min read time

In the world of palletizing, the debate between standard and customized solutions is a hot topic. As businesses strive for safety, efficiency, productivity, cost savings, scalability, versatility, reduced downtime, ease of maintenance, and long-term investment, the choice between standard and customized solutions becomes critical. This article illuminates these aspects, underscoring the advantages of standard solutions over the potential risks of custom palletizing solutions.

What to choose?

Before getting into the specifics, let us make a quick analogy between a business' need for automation and robotics and its need for an ERP solution well-fitted for its reality. With the need to automate their processes, many businesses have faced the need to implement a new ERP (Enterprise Resource Planning). Maybe it is the case for your business.

When choosing the ERP, you most probably needed to make a choice between a standard or a custom solution. Much like standard robotic solutions, standard ERP systems are designed to address a wide range of business needs, with built-in modules offering scalability and adaptability as the business grows and evolves. They are built on best practices and have been tested extensively, ensuring reliability and efficiency.

On the other hand, custom solutions, whether in robotics or ERP systems, are tailored to meet very specific needs. While they may provide a precise fit initially, their adaptability can be limited as business needs evolve. Custom solutions also require significant resources for development and maintenance, which can lead to higher costs in the long run.

Safety and efficiency

Standard Solutions: A Safe and Efficient Choice

Standard palletizing solutions are designed with safety and efficiency at their core. These solutions are backed by proven methodologies and extensive testing, ensuring they meet industry safety standards and operate at peak efficiency. The use of standardized components and software also means that these solutions are reliable and predictable, reducing the risk of unexpected issues, downtime, or safety hazards.

Furthermore, given that a standardized solution is thoroughly tested prior to installation, the deployment process of a Turnkey Solution generates minimal downtime.

The Hidden Risks of Customized Solutions

While customized solutions may seem appealing due to their tailored approach, they often harbor hidden risks. Lacking the extensive testing that standard solutions offer, safety, and efficiency can be compromised with a customized solution. Custom solutions may also lack the robustness of standard solutions, leading to potential operational issues down the line. Each customization introduces new variables, potentially leading to unforeseen complications that can compromise safety and disrupt efficient operations.

Cost and Scalability

The Economic Advantages of Standard Solutions

Standard solutions offer significant cost-saving potential, as they eliminate the need for expensive custom development. Furthermore, standard solutions are inherently scalable, allowing businesses to easily expand their operations without the need for costly and time-consuming customizations.

The Financial Pitfalls of Customized Solutions

Customized solutions, while potentially offering unique benefits to a very specific need, can also lead to significant cost implications and scalability issues. Custom development is often expensive, and the resulting solutions may not scale efficiently as your business grows. This can lead to escalating costs and operational challenges in the long run: additional software development for new needs, new parts responding to a new reality, etc.

Versatility and Reduced Downtime

The Operational Benefits of Standard Solutions

Standard solutions offer versatility and play a crucial role in reducing downtime, thereby enhancing productivity. With a standard solution, businesses can adapt to various operational needs without extensive downtime for customization. This flexibility ensures that operations continue smoothly, even as needs evolve.

As they are specifically conceived for palletizing, every scenario regarding palletizing itself, every infeed possibility, the materials to be palletized, speed, and trajectories are evaluated and taken into consideration. On the other hand, a customized solution will have a very unidirectional vision of a specific application to be accomplished.

The Operational Challenges of Customized Solutions

Customized solutions, however, can increase downtime and maintenance requirements. Each customization requires time to implement and may introduce new points of failure, leading to more frequent maintenance and unexpected operational disruptions. Having to make a change in a configuration can become very complicated with a customized solution. Rare are businesses having an in-house software developer. You will then need to defray the costs of a professional developer.

Even worse, imagine a team member of your integrator who developed the code for your software. A few years later, your business has evolved and now has new needs that require a new code for the software. If the integrator’s employee is not working there anymore and has left with his or her knowledge, there could be an additional cost and complexity there.

Ease of Maintenance and Long-term Investment

The Sustainability of Standard Solutions

In terms of maintenance and long-term investment, standard solutions shine. They offer ease of maintenance and make for a sound long-term investment. Their proven reliability and lower maintenance requirements ensure they continue delivering value over time.

The Uncertain Future of Customized Solutions

Customized solutions, while potentially offering a perfect fit for specific needs, can come with an uncertain future. Their reliance on custom parts and tailored software code can lead to increased maintenance requirements and potential issues with scalability and adaptability.

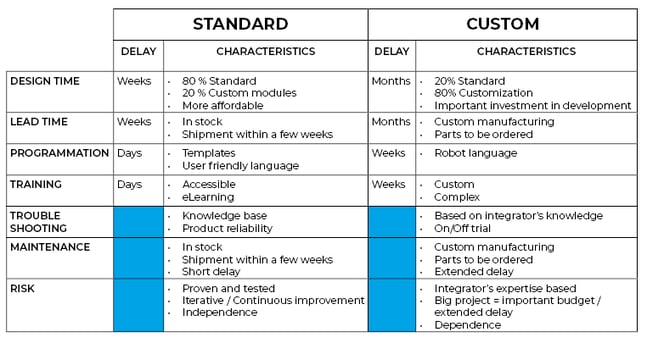

The following table summarizes the difference between both types of solutions:

Customized Solutions: Tailored for Specific Needs, but…

While customized solutions are conceived to respond to a specific requirement, the potential risks and challenges associated with these solutions cannot be overlooked. The hidden costs, increased downtime, and uncertain future of customized solutions make them a risky choice for businesses.

The Clear Choice

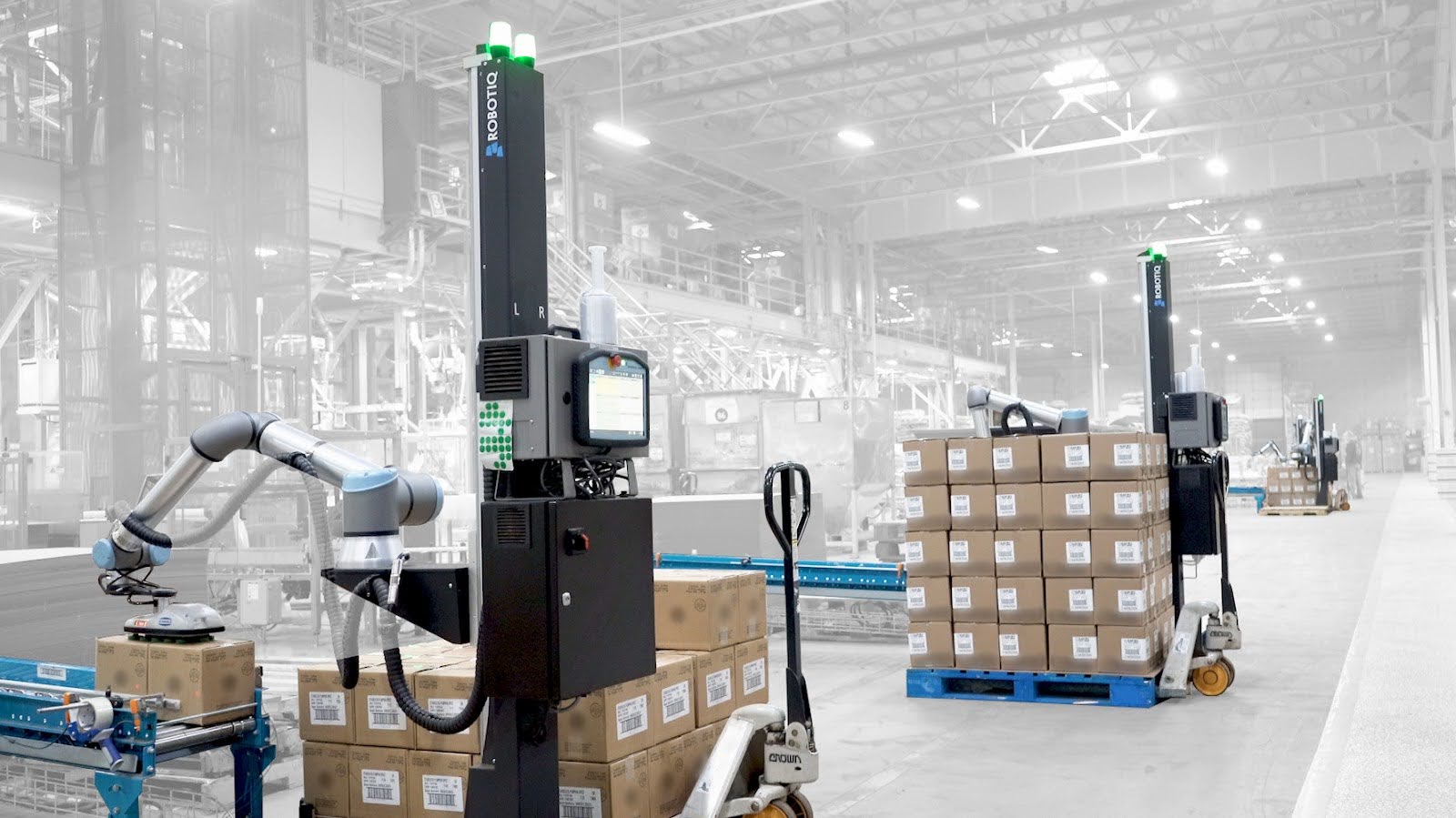

In light of these considerations, standard solutions, like those offered by Robotiq, emerge as the clear choice. Their proven safety, efficiency, and cost-effectiveness make them a reliable choice for businesses looking to optimize their palletizing operations.

Robotiq offers a range of standard palletizing solutions designed to meet the needs of businesses of all sizes. Our solutions are designed to deliver safety, efficiency, and scalability, providing businesses with a reliable and cost-effective solution for their palletizing needs. Choose Robotiq, and let us help you optimize your operations for success.

In order to make the right decision, you need to ask yourself what you want to optimize in your business: performance (speed and/or precision), ROI, flexibility, etc. How do you want to optimize it? Do you want to be autonomous in your company's growth or do you want to be depending on an integrator and his lead time to develop a solution that will fit your new needs?

Are you thinking about automating your end-of-line processes? Connect with an expert.

Leave a comment