RIA International Collaborative Robots Workshop - 5 Key Takeaways

Posted on Oct 03, 2014 12:04 PM. 5 min read time

I am just back from San Jose, California, where I had the chance to speak and attend the 2nd RIA International Collaborative Robots Workshop. My talk was on Grippers for Collaborative Robots. The workshop was well attended by end users, vendors and integrators. Conclusion: Collaborative robots are more than buzz words. They're shaking the market and are about to change the game of industrial automation. Here are my notes from the event.

1. Yes, there are Many Types of Human-Robot Collaboration

Erik Nieves, Technology Director at Yaskawa Motoman, gave an introduction explaining the four different types of collaboration possible between a human and a robot according to ISO 10218:

- Safety-Rated Monitored Stop

- Speed and Separation Monitoring

- Hand Guiding

- Power and Force Limiting

2. Robot End Users are (almost) all-in

The event ended with an end-user panel that presented two speakers from automotive (Stefan Bartscher from BWM, Marty Lin from GM), one from electronics (John Dulcinos from Jabil) and one from laboratory automation (Dane Sipes from Novartis Foundation). What was clear for them was that collaborative robots that can easily be deployed and retasked will be a major game changer for their industries. For the automotive industry, it will increase ergonomics and productivity. The flexibility collaborative robots incorporate will help to cope with the increasing complexity of making more and more car models with more and more (lucrative) options. For Jabil, the vision is to be able to interchange seamlessly human assemblers and robotic stations: same space, same tool, same input and same quality output. Because this industry is seasonal and needs very aggressive production ramp up, the robots need to be flexible so they can be reused from one product to another to make any ROI possible. Oh, and the part feeding problem needs to be solved first before anything else.

When collaborative robots can offer more capability and more safety, we'll remove the 'almost' from this subtitle: these large end-users are a giant potential market for purchasing thousands of collaborative robots... Just like the small shops are already doing today on a smaller scale.

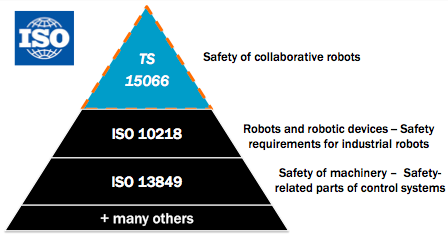

3. Collaborative Robots: Safety is the Name of the Game

I think every single presentation throughout the whole day mentioned the word safety at least 5 times. There is still a lot of uncertainty, research and debate going on in the robotics industry around the upcoming safety standard for collaborative robots (TS 15066).

Esben Østergaard from Universal Robots reminded us of the Red Flag Act, under which the first locomotives needed to be preceded by a walking person baring a red flag when they initially appeared in the UK. His message was intended for the ISO committee: End users really want collaborative robots, make sure these robots are safe, but don't forget that excessive safety should not make them useless.

Björn Matthias from ABB presented their approach to safety. Their upcoming YuMi will have a very small payload on purpose in order to be the safest collaborative robot out there. He also presented a mathematical model of human-robot contact events that will definitely not be used as it stands in small shops, but that could definitely be an interesting design tool.

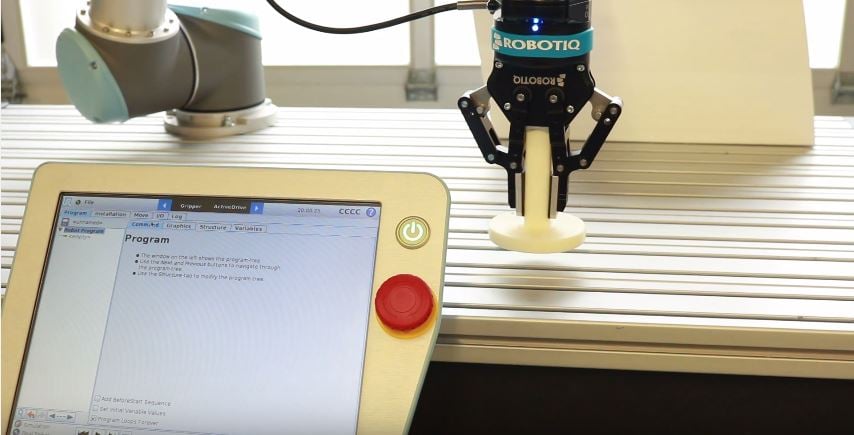

The key notion in robot safety: risk assessment. Having a certified robot and a certified gripper will not mean you'll have a safe application. Every application will be different and must be treated independently. This is not an easy problem for those end-users wanting to deploy 1,000s of robots.

4. Collaborative Robots are so 2012

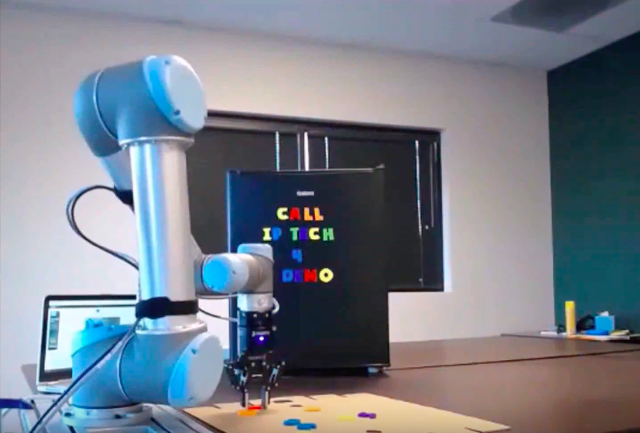

Rodney Brooks from Rethink Robotics applied his proven recipe to put the robotic technology in perspective, namely to give us examples of how computers have evolved rapidly in the last 30 years. He got out some vintage pictures of the first printer he'd used while he was still a kid (that had a red emergency stop button!) to illustrate how the capabilities and the human-machine relationship has evolved. We could also see fresh videos of Baxter at work in factories and in their lab. Brooks showed how force control can be used to compensate for a compliant mechanics and how simple tricks such as placing fiducials on work tables can help the robot understand its environment. The passionate roboticist argues that collaborative is just the tip of the iceberg and that in 5 years we'll have 100s of new adjectives to describe completely new capabilities of our rapidly evolving robots. And then he finishes by warning that history tells us that "those who use regulation to resist change will lose".

5. We just Need a Cheap Arm and a Brain

SRI's Rich Mahoney gave a glimpse of the future of collaborative robots with some examples coming from their organization. According to Mahoney, key pieces are already in place for the exponential growth of robotics: communication, mobility, perception, processing. He forecasts that the only two big missing pieces are:

- Cheap arms & hands -- to be solved in 3-5 years

- AI to improve awareness, intelligence and interaction -- to be solved in 3-8 years.

Wish you were there? Don't miss the Next Collaborative Robots Workshop to be held at Automate 2015!

Leave a comment