Universal Robots' New Functionalities

Posted on Nov 26, 2013 1:44 PM. 4 min read time

Nowadays, automation is now really accessible to medium and small companies through collaborative robots. These small industrial robots can accomplish various tasks around human workers without any barriers. This application is made possible with their integrated safety systems. Even if they use different technologies to prevent damage or injuries, the collaborative robots are regulated by the robotics safety standards : Safety Standards for Collaborative Robots.

One of the major industrial robot manufacturers in collaborative robotics, Universal Robots, recently announced two new functionalities for their robots UR5 and UR10: Force control and a dual arm system.

Force control

The latest software upgrade for Universal Robots now allows for a better force control of the robot’s movements. Tasks needing a delicate touch such as handling fragile objects or food can now be easily accomplished with the UR5 and UR10. The force applied by the robot is therefore variable, offering great flexibility for manipulations.This technology is often offered as an option from other manufacturers, but Universal Robots offers it for all its users.

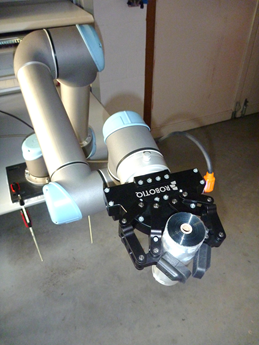

Since force control is also one of the key features of Robotiq's end effectors, a robot gripper, such as the 2-Finger Adaptive Robot Gripper - 85, could be integrated with the robot arm in order to merge the two force controls. This would allow a greater control of the grip through the robot arm itself. Note that Robotiq has developped a sofware package for Universal Robots to make the programming of its electric grippers easier.

According to the UK and Nordic Sales Manager, Kristian Hulgard, a key selling point of the Universal Robots' products are their constant evolution through upgrades. Once a customer purchases a product, he will benefit from all the new features of the latest technologies for its product.

Dual Arm Torso

This concept has already been seen with some collaborative manufacturers and Universal Robots is now offering it to its clients. This concept is about imitating the way humans work with two arms working together. The two arms are programmed to work in unison and with force control, in order to provide just the right grip on objects.

UR’s Goal

The main objective for Universal Robots is to provide efficient robotic technologies to small and medium sized companies. They succeed by offering robots that can be easily added to any production line since it is a plug-and-play solution. Then, they can be easily programmed through demonstration and without knowledge in programming. Their collaborative feature also allows the robots to be installed without barriers in 80% of the installations.

The technologies used for their collaborative feature are patented by the company and they consist in measuring the electric current in the joints to determine the force and movement of the arm. This technology is one of the reasons for its affordability.

To conclude, the UR5 robotic arm was announced as “The world’s most innovative robot” by The International Federation of Robotics and IEEE Robotics and Automation Society in 2012. So, we are sure that more interesting features on these products are coming.

For more information, visit their website: Universal Robots

Leave a comment