4 Mistakes to Avoid When Automating a Process

Posted on Jul 26, 2016 7:00 AM. 4 min read time

We all make mistakes at some point or another. Here are some reminders on what you want to avoid when automating a process. And believe me, there are not just beginner’s mistakes!

Mistake #1: Thinking automating a process means programming your current process in a robot

NAAAAN. (Hear the ‘wrong answer’ buzzer?)

Of course, you have your current process, and it works well as it is. You just want to plug it in a robot that will accomplish the same sequence, and Ta-DAAA! Well, not exactly.

Automating a process often means changing it. The core of the process might stay the same and will only need tweaks along the way. But the process steps might change completely, even though the result will be the same. Think of it this way: the operator has 2 hands, 2 eyes and a brain full of knowledge. The robot, on the other hand, has 1 or 2 hands, maybe no visual sensor at all, and limited knowledge (based on how it has been programmed). Considering this, the process might be handled differently. Therefore, you need to sit back and rethink the process with the material you will be using. Now is the time to jot down the decision tree that will be programmed into the robot.

Here are some tricks that might help:

You might start up by automating just one of the process steps, and work your way up.

If your application is to automatically paint a car, you could start small by automating only the loading of the painting gun, then let the operator do the painting himself: the robot would read a barcode from the order sheet that identifies the color, pick the correct color from a dispenser, and load the painting gun that would be used by the operator. Starting small will let you familiarize with the equipment, the way of thinking for automating things, etc.

If you automate only a few of the process steps, you will still gain in productivity, and the return on investment might be better, because you will not try to automate the sections of the process that really depend on tacit knowledge. Therefore, the automation should be faster. You will redirect the talent of your employees from the dull steps to the steps where their expertise is really needed. Chances are that your employees will start to see the possibilities of the robot when working with it, and might come up with new ideas on how the process could be fully accomplished with the robot eventually.

Mistake #2: Skipping a proper simulation

Mistake #2: Skipping a proper simulation

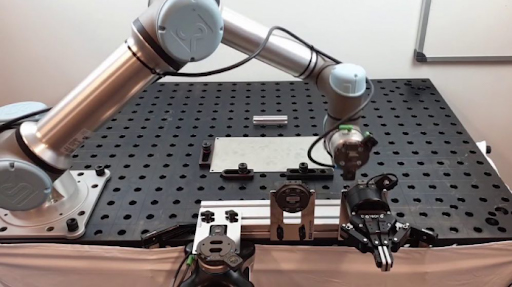

If the automated process is different than the manual one, simulate the future process by doing the same thing yourself. You could even cover up your eyes and work with big gloves (if it’s not dangerous, of course!) to simulate not having your touch & see sensors if you don’t plan on adding those to the robot. A second step would be to simulate it on a robot simulator and check if the tasks you have planned for the robot seem feasible in terms of robot reach, possible collisions with its environment, etc. Having done the simulation, you can adjust the plan for your automated process accordingly.

Mistake #3: Overlooking all possible cases that could occur

So you’ve automated the process as it usually is: pick up a part, bring it to some machine, leave it there, wait for signal, take the part again, bring it back to its original position. Then take the next part, etc.

But what if… there’s no part to pick up? What if the signal to take back the part doesn’t occur? What if the signal to take back the part occurs, but there’s no part there?

The same principle applies in programming, when you want to make sure you cover the case of ‘division by zero’. You have to jot down your process and make sure every branch of the logical tree is covered.

Mistake #4: Under test

This is so very common, and not only in automation. I’ve once had a university colleague who was learning to code, and at some point she had said: yay, I’m done, it compiles!! o_O. (Of course, the underlying question is: OK, but does it WORK?).

To test the robustness of your solution, change variables that might vary in real life: close the ambient lights, start a drilling process close by (that will induce some vibrations on your robot), increase the ambient temperature, etc.

Pro tip #1: Remember to save funky parts from previous batches instead of discarding them in the scrap pile. You could use them as ‘extreme cases’ to check how the robot will behave.

Pro tip #2: Design your test BEFORE automating your process. This will achieve 2 goals: 1- you will not adapt your test to the way you have programmed your process; and 2- thinking ahead of how you will test your automated machine will make you think of its variables. You can then design your automation accordingly.

Pro tip #3: When you can use one, having a golden template is good practice: after calibrating the machine, you can check that its behavior is still appropriate by checking the results with the golden template. Of course, this is valid only with non-intrusive processes, as you cannot test a grinding process every day on the same ‘golden’ part.

Find out more tricks and ways to ease the automation of your process by reading our new eBook on the subject. Click the banner below and get your free eBook now.

Leave a comment