New Robotiq Vision System Breaks Down Integration Barriers

Posted on Jan 02, 2017 7:00 AM. 2 min read time

Already almost half a year since the launch of Robotiq’s Plug+Play Vision System, can you believe it? We’re proud to see the camera make its way on more and more factory floors! Take a look back at our official launch.

For the holidays we decided to feature our best blog posts of the year. Go back in time and take a look at the highlights that mark the end of a great year of robotics.

Early users of the system say Robotiq’s Camera opens new possibilities for automation: “The Robotiq Camera breaks all the integration barriers that we are used to see with vision systems in manufacturing automation. We could think of many pick & place robot tasks that can now be programmed very fast. We will need this solution for upcoming projects with UR robots,” says Victor Canton, Manufacturing Engineer, Continental Automotive Spain SA.

“We kept seeing projects that would work much better with machine vision, but manufacturers stayed away because of the complexity and cost of existing solutions,” explains Samuel Bouchard, CEO of Robotiq. “This is why we have set out to create a camera and vision software that could be set up and used by anyone.”

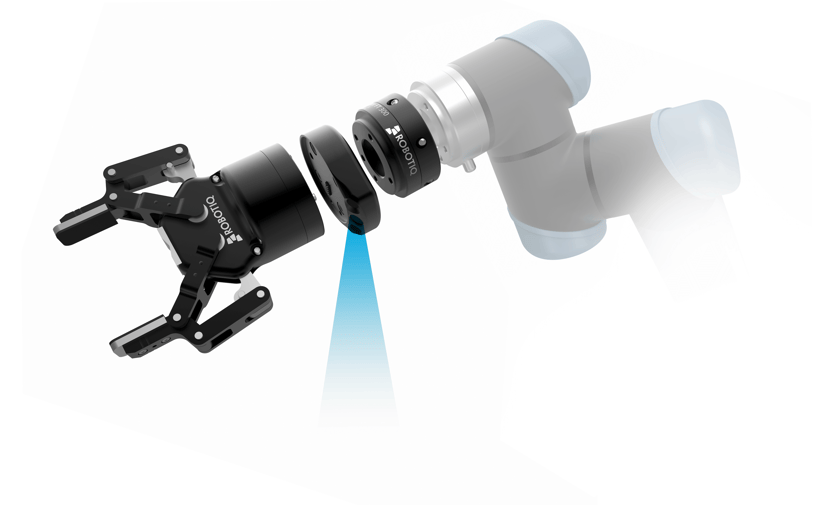

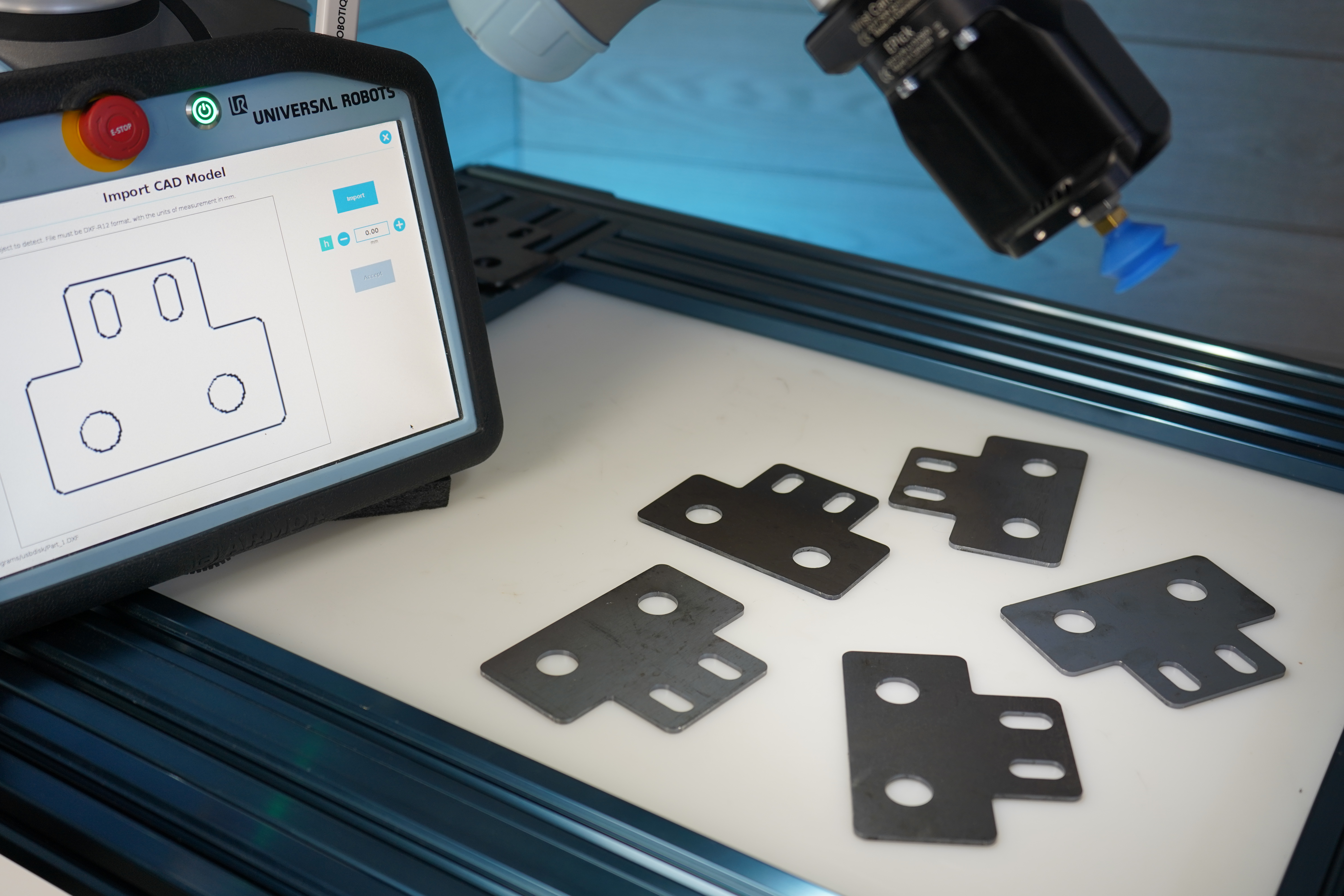

The compact camera design fits perfectly on the UR wrist and offers direct connectivity to the controller. Moreover, the Robotiq Camera’s user-friendly software is seamlessly embedded within Universal Robot’s graphical user interface. There is no external PC required to setup, program or run Camera. Everything is done right from the robot user interface.

You can teach Robotiq’s Camera a new part in just 5 minutes, and it will locate the part in its field of vision. Because of its unique wrist mount design on the UR, this robot vision system does not need complex calibration procedure or extra external illumination. Being mounted on the robot's wrist also has the benefit of expanding the search area without dealing with complex fixtures. “The robot's arm moves, so the Camera can locate the parts in a wider work area,” explains Jean-Philippe Jobin, Robotiq’s CTO.

Here is a demonstration of the simple steps in order to use the camera:

Robotiq’s vision system for Universal Robots is commercially available now. A live demonstration of the product can be seen at Robotiq’s booth at Automatica 2016, Hall B5, booth 512.

For more details visit the Product Page.

Leave a comment