Yes, Collaborative Robots Can Be Repurposed in a Changing Production Environment

Posted on Aug 15, 2016 7:00 AM. 3 min read time

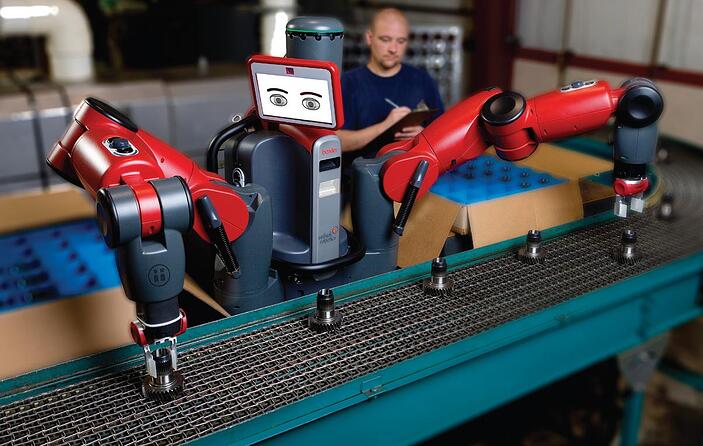

Fast turnaround is a necessity for small and medium manufacturers. Companies that can find ways to decrease lot sizes and produce small, custom runs gain a competitive edge over those with long lead times. Can robotics and automation be effective in a variable production environment? With traditional industrial automation, the answer is usually no. Large, high-volume, single-purpose workhorses are productive but not flexible. In contrast, collaborative robots are extremely flexible and adaptable, making them ideal for use in both high- and low-volume production runs.

With collaborative robots, some parameters are fixed, such as the reach radius, axes of movement (also known as degrees of freedom), and payload. For example, a UR5 from Universal Robotics is a 6-axis arm with a maximum payload of 5 kilos, and cannot be re-purposed to handle a higher payload.

However, despite fixed parameters like payload, three main features of collaborative robots make them extremely well-suited to repurposing. Mobility, re-programmability, and modularity of the end effectors, or end-of-arm tooling, are advantages that allow collaborative robots to be easily re-deployed.

Mobility

Unlike traditional industrial robots, collaborative robots are cage-free, lightweight, and have a small footprint. Since only a small space is required, they can easily be set up in a new station without re-configuring the entire production floor. They’re so light, they can even be mounted on a mobile platform to be wheeled around from one area to another. The UR5 from Universal Robots weighs only 18 kg (41 lbs)! Mobility is a major advantage that allows collaborative robots to be deployed where they’re needed, just like a workforce.

Unlike traditional industrial robots, collaborative robots are cage-free, lightweight, and have a small footprint. Since only a small space is required, they can easily be set up in a new station without re-configuring the entire production floor. They’re so light, they can even be mounted on a mobile platform to be wheeled around from one area to another. The UR5 from Universal Robots weighs only 18 kg (41 lbs)! Mobility is a major advantage that allows collaborative robots to be deployed where they’re needed, just like a workforce.

Re-programmability

Collaborative robots are designed with agility in mind. As long as the main unit and the end effector have the capacity to perform the new task, a collaborative robot like the UR5 can be re-programmed quickly. A library of programs for recurring tasks can even be stored for fast retrieval and quick re-deployment. End effectors like the Robotiq 2-Finger and 3-Finger Grippers provide the ability for the robot to grasp a wide range of different objects without changing the robot or end tool. The Robotiq 2-Finger 85 Gripper can even control the force exerted, allowing it to pick up fragile and brittle parts, as well as sturdy pieces. Watch this video to see how easy it is to program a UR5 equipped with a 2-Finger Adaptive Robot Gripper.

Modularity of the End Effectors

A collaborative robot like the UR5 can perform many tasks by using different end-of-arm tooling like suction cups, Grippers, dispensing, cutting, drilling, or deburring tools, and more. With this

A collaborative robot like the UR5 can perform many tasks by using different end-of-arm tooling like suction cups, Grippers, dispensing, cutting, drilling, or deburring tools, and more. With this

range of end options, a UR5 can feed a CNC machine, pick, pack, glue, dispense, and perform many other operations. Changing the end effector is not as fast as simply re-programming the same end effector to perform a new task. However, tool changers can be used to make it easier for a robot to use different end-of-arm tooling. Learn more about different end effectors in this free eBook.

Re-deployability makes collaborative robots even more attractive when calculating potential return on investment. The probability of downtime is greatly reduced when you factor in the capacity for the robot to be re-programmed, moved, and adapted with a new end effector. For example, in a short production run, the same robot could be re-deployed to drill parts, glue assemblies, and pack orders. Of course, safety and suitability must be taken into consideration before re-deployment, but collaborative robots are proving to be much more flexible than their dedicated predecessors.

Leave a comment