What's New in Robotics This Week - Sep 29

Posted on Sep 29, 2017 7:00 AM. 12 min read time

-Manufacturing & Cobot Roundup

-Welcome to the Robot Dentist

-Hey! Nunchucks!

-The Art of Falling Over

...and much more!

Manufacturing & Cobot Roundup

New figures from the International Federation of Robotics (IFR) estimate that global robot installations in 2017 will increase by 21 percent in the Asia-Australia region, by 16 percent in the Americas, and by 8 percent in Europe.

The IFR is predicting that by 2020 more than 1.7 million new industrial robots will be installed in factories around the world.

From the press release:

"Important drivers of this development: robot adoption is a response to faster business cycles and the requirement to produce with greater flexibility tailored to customer demand in all manufacturing sectors. A new generation of industrial robots will pave the way for ever more flexible automation."

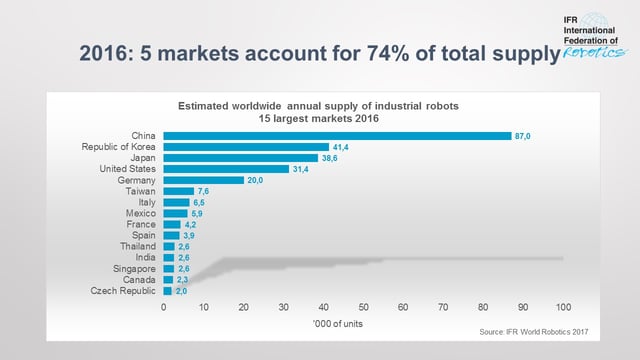

Figures for 2016 were also released...

Source: International Federation of Robotics

Global sales of industrial robots rose by 16 percent in 2016, driven by the electronics industry. The global market was worth around $13.1 billion, rising to an estimated $40 billion, if you include software, peripherals and systems engineering.

The IFR also provided some interesting comment on how increasing adoption of automation among small-to-medium size companies will drive future adoption of robotics:

Simplification is a key trend for this market segment. The ongoing need for robots which are easier to use and to program and the increasing need for ever more flexible automation initiated the development of smarter solutions. This is especially useful for industries with a lack of specialized production engineers in-house. Thus, it is important to provide easy-to-use robots that can easily be integrated into and operated in standard production processes. Robots that are uncomplicated to use will enable the deployment of industrial robots in many industries to sustain efficient and flexible manufacturing.

Reuters has more.

Lean Robotics is a methodology and set of tools designed to help you deploy automation safely, effectively, and with less time and effort than is traditionally associated with robot deployment.

At Robotiq's recent 24-Hour Workshop Challenge 7 of 8 teams succeeded in designing and implementing an automated cell involving 5 cobots performing an assembly task within the allotted time period.

DENSO Robotics announced the introduction of its latest HSR four-axis SCARA robot this week. The new model is designed for high-speed, high-precision pick and place in assembly processes, as well as packaging processes in the food, medical device, pharmaceutical and cosmetics sectors.

Reduced shaft whip and settling time, along with a lighter-weight arm and an optimized arm structure, make the HSR more efficient than previous models, enabling it to accelerate faster, run continuously at its highest rated speed and stop more precisely.

Standard cycle time (with a 2-kg weight) of the HSR robot is from 0.28 to 0.31 sec. and repeatability is from ±0.01 to ±0.12 mm. Maximum payload capacity is 8 kg, with available reaches of 480, 550 and 650 mm.

ABB purchased General Electric's Industrial Solutions business for USD2.6 billion.

Researchers at the Humans to Robots Lab at Brown University released video showing some of their work on grasping and teleoperation using cobots...

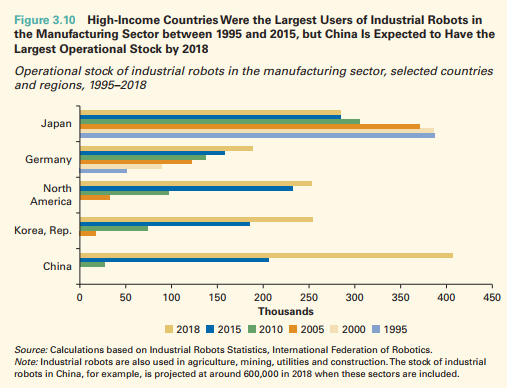

China's robot revolution may impact on developing countries, according to the World Bank.

The fast pace of automation in China is not only threatening local low-skilled workers, but could affect opportunities for export-led development in other countries, too.

The Washington-based development bank said in the report titled “Trouble in the Making? The Future of Manufacturing-Led Development” that advanced robotics, 3D printing and smart automation are new factors influencing which locations are attractive for production.

Separately, US Commerce Secretary Wilbur Ross, expressed the view this week that increasing adoption of automation in China is a threat to the US economy, the Financial Times reported.

Engineering.Com took a look at Mecademic's desktop-size industrial robot arms:

Weighing in at just 4.5 kg (9.9 lbs), the Meca500 has a total reach of 260 mm (10 in) and a payload of 500 g (1.1 lbs).

Its most noticeable feature is the lack of an external controller—instead, the controller is embedded in the robot’s base, giving the robot an even smaller footprint.

China is embracing smart factory technology in its manufacturing arms race with Germany and Japan, the South China Morning Post reported.

Not strictly a cobot story, but this one is interesting in terms of where human-robot interaction might be headed: The Telegraph reported that a recent UK survey conducted by WorldPay found that two-thirds of Britons aged between 21 and 34-years old would be happy to pay for goods and services via machine rather than through another human being.

Welcome to the Robot Dentist

A Chinese robot dentist has become the first to fit implants in a patient’s mouth without any human involvement.

South China Morning Post reports:

The one-hour procedure took place in Xian, Shaanxi, on Saturday. The implants [created using 3D-printing] were fitted to within a margin of error of 0.2-0.3mm, reaching the required standard for this kind of operation, experts said. The technology was designed to overcome mainland China’s shortage of qualified dentists and frequent surgical errors.

USA Today noted that similar technology has been cleared for use in the United States: "In March, health care company Neocis confirmed receiving approval from the U.S. Food and Drug Administration for Yomi, a robotic system for dental implant procedures."

Hey! Nunchucks!

Researchers have trained a robot to flip nunchucks as a way of demonstrating the efficacy of a new, intuitive approach for teaching complex manual tasks.

Best of all, the learning method is non-task specific, so the range of potential applications is huge.

First, the teacher explains each step of the trick using an intuitive symbolic flow chart called a Petri net. Then, they demonstrate the trick and evaluate their own performance after every attempt, creating data the robot uses to learn the movements required at each step and develop criteria for self-evaluation as it practices. It took the robot a matter of hours to learn how to spin the nunchuck around the back of its hand and catch it again.

From the team's paper:

Advanced motor skills are essential for robots to physically coexist with humans [...] In this paper, we present a composite learning scheme which goes beyond LfD [Learning from Demonstration] and integrates robot learning from human definition, demonstration, and evaluation. The method tackles advanced motor skills that require dynamic time-critical maneuver, complex contact control, and handling partly soft partly rigid objects.

Inverse sounded a note of caution, arguing that there are economic reasons to be concerned about this new learning system.

The Art of Falling Over

Just like their biological brethren, humanoid and bio-inspired robots fall over sometimes.

With this in mind, researchers from the University of Tokyo and Kawasaki Heavy Industries are working on a life-sized humanoid that's able to right itself when circumstances require it.

IEEE Spectrum reports that instead of trying to develop strategies to avoid falling over, the team has taken a fresh approach; "they’ve built their robot from the ground up with an armored structure that makes it totally okay with falling over and getting right back up again."

Meanwhile, roboticists at the University of Illinois have created a prototype, bio-inspired bot that can snap itself upright using a spring-loaded mechanism similar to that found in the click beetle.

Via DigitalTrends:

“Robots inspired by animals are not really new but they usually focus on improved stability and balance,” Aimy Wissa, lead investigator of the project, told Digital Trends. “But falling is inevitable. Rather than creating legs that can locomote, balance, and get help with self-righting we think that looking at nature to find ways of self-righting that do not involve legs would make the robot’s design simpler and more robust."

Self-righting robots, we salute you! In the immortal words of one-hit wonders, Chumbawamba:

"I get knocked down, but I get up again

You're never gonna keep me down."

I may get knocked down too, but like a determined click beetle, I'll be back next week with more news from the world of robotics.

Until then, I hope you enjoy these videos and links!

Bio-inspired retina allows drones to almost see in the dark with no motion blur (ZDNet)

Toyota’s new self-driving car has two steering wheels to prevent robot joyriding (The Verge)

Roboburgh, robot belt, robotics row. But will these Burgh buzzwords stick? (Pittsburgh Post-Gazette)

This 3D Printed Humanoid Robot is Learning Sign Language to Support the Deaf Community (Core77)

Zoom.ai Acquires SimplyInsight (PR News Wire)

Slave/Master At The V&A Challenges Public Perception About Robots Through Dance (Huffington Post)

How Switzerland Became The Silicon Valley Of Robotics (Forbes)

Is Esben Østergaard the Henry Ford of Robotics? (Asian Robotics Review)

Do we need a robot tax for businesses (The Telegraph)

6 reasons why robots would make better rulers than politicians (Metro UK)

Leave a comment