What’s New in Robotics? 28.10.2022

Posted on Oct 28, 2022 7:50 AM. 8 min read time

News briefs for the week take a look at the return of PACK EXPO International after its 4-year COVID-caused hiatus from the tradeshow circuit. The producers promised a big-bang reentry, and they delivered, calling it One Powerful Show. From the perspective of robots and cobots, however, it was a dominating performance. From what was in evidence on the show floor, evermore dominance in robot-driven automation is coming in the very near future.

One show, two takeaways!

Upon hitting the show floor, the jump-out realizations to grab onto at Pack Expo 2022 are two: More cobots doing more things better and more flexibly than ever; and then, upon closer inspection of those same cobots, the fact that integration of cobot systems is the  next great advance in robotics. If that’s all you took away from the show, you would have, in a nutshell, seen the future of packaging and packing.

next great advance in robotics. If that’s all you took away from the show, you would have, in a nutshell, seen the future of packaging and packing.

The editors for the show’s producer PMMI (The Association for Packaging and Processing Technologies (formerly Packaging Machinery Manufacturers Institute)), noticed the cobot population increase right off, as they walked the floor to report on their first impressions.

“Collaborative robots, or cobots, are increasing their impact on packaging systems. It used to be that robots on the show floor had to be given a wide berth. It is still a little surprising to see these cobots free of any enclosure, where attendees are free to interact with them.”

Within those two realizations exists a world of variety, flexibility, and built-in “intelligence.” Amazing is the seepage of robotics into nearly every aspect of packaging, packing, and production.

KUKA, ABB & Beckhoff

KUKA’s Chad Dukart, showed off one such integration with KUKA’s Pick Control system that uses “smart” vision software to  simultaneously control the actions of a 6-axis cobot, two Delta robots and a SCARA robot all working the same conveyor line picking and packing product in what he called, “robot-based software for conveyor tracking with integrated image processing.”

simultaneously control the actions of a 6-axis cobot, two Delta robots and a SCARA robot all working the same conveyor line picking and packing product in what he called, “robot-based software for conveyor tracking with integrated image processing.”

With product cycles getting shorter and shorter, while resource and energy efficiency are receiving ever greater attention, flexible, integrated production solutions are in demand. He said that he could, for example, with the touch of a button, have one or the other Delta robots work faster or slower, and still the conveyors full of product to be packed would remain in sync.

ABB showcased a standard IRB 360 FlexPicker that displayed another new cobot skill in picking integration: artificial intelligence “that  allows the robot to learn and adapt to a wide variety of items including cuboids, cylinders, pouches, blisters, and random shapes, as found in electronics, pharma, healthcare, cosmetics and other consumer product industries.”

allows the robot to learn and adapt to a wide variety of items including cuboids, cylinders, pouches, blisters, and random shapes, as found in electronics, pharma, healthcare, cosmetics and other consumer product industries.”

ABB claims that the FlexPicker’s internally developed AI solution provides unprecedented accuracy with a “first-time, right-pick rate of 98.5%, and picking efficiency of >99.5 %,” in picking items from unstructured scenery; and because of reduced computing time, “peak pick rates of up to 1,500 items per hour.”

In what was reminiscent of snap-together toys, Beckhoff showed up with ATRO, a modular industrial “snap-together” cobot system “that can be used to assemble the optimal cobot structures for different applications on an individual and flexible basis.”

Need a 4-axis cobot today, a 6-axis cobot tomorrow, and maybe a 7th axis thrown in just in case? Well, the ATRO (Automation Technology for Robotics) system is comprised of standardized motor modules with integrated drive functionality, and link modules of various designs and lengths.

Need a 4-axis cobot today, a 6-axis cobot tomorrow, and maybe a 7th axis thrown in just in case? Well, the ATRO (Automation Technology for Robotics) system is comprised of standardized motor modules with integrated drive functionality, and link modules of various designs and lengths.

Beckhoff says that all ATRO modules “feature an internal media feed for data, power, and fluids (vacuum, air, and water). This allows ATRO to use a variety of tools, such as mechanical, pneumatic, or electric grippers. Because these media feeds are internal, it allows for endless rotation of ATRO axes and end effector tools, as there are no external cables to hinder the robot’s range of motion.”

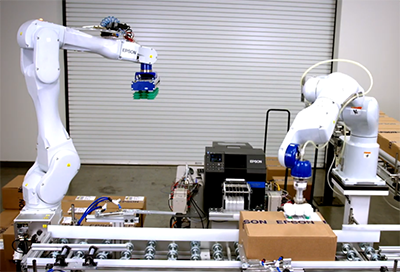

Epson partners with itself!

If you are Epson and known for color printers, you are also known for cobots. Out of a unique partnering between Epson’s cobots and  printers sprang a novel, new way to print labels and then affix them to packages as they travel along a conveyor.

printers sprang a novel, new way to print labels and then affix them to packages as they travel along a conveyor.

That’s the idea behind Epson showcasing its VT6L All-in-One 6-Axis robot with built-in controller paired with the Epson ColorWorks C6000 Series color inkjet label printer.

It’s also a great example of the versatility in design and capability that cobots are bringing to automation, especially at Pack Expo where all the versatility can be seen and experienced within walking distance from one to the other on the expo floor.

Epson can also be credited with another unique, world’s first, with its adaptation of 6-axis design cobot with a “folding” arm kinematic configuration (see photo).

Great for working in tight spaces, the compact arm of the Flexion has the ability to fold through itself, versus moving around itself. Epson claims that it uses 40% less space than a standard 6-axis arm and can easily work within an envelope of one square meter, which is ideal for space-constrained medical and pharma labs.

Cobots take on the mighty shipping pallet

The humble but mighty wooden shipping pallet (48 in × 40 in or 1,219 mm × 1,016 mm), with over 2 billion in use worldwide, has been the global transport standard for near one-hundred years. The modest pallet is so powerful a shipping medium that it’s been elevated  to verb status: hence, to palletize; and its reverse, to depalletize.

to verb status: hence, to palletize; and its reverse, to depalletize.

All manner of human and software calculations have been devised on how best to pack pallets and then to stabilize their loads for safe, efficient, and least costly transport. Humans charged with loading pallets is pure, brain-numbing drudgery…and expensive, but, more often than not, humans get the job, if, that is, enough humans can be found to hire.

Automating palletizing and depalletizing would be an industry dream come true. Caged-off robots do it most often, but in out-of-the-way shipping areas far away from people and isolated from the flow of production.

Cobots are the latest to take on the challenge of automating the packing of the mighty shipping pallet. Pack Expo even had a Logistics Pavilion with 25 aspiring packing/packaging companies, with some looking to take on the challenge.

To win the palletizing/depalletizing challenge is to have a highly mobile, go-anywhere-in-factory-or-warehouse cobot that could work amid humans and normal production flows, work long hours at near maximum payload, quickly pack out a pallet, and then be nimble enough to move on to the next pallet in a hurry.

To win the palletizing/depalletizing challenge is to have a highly mobile, go-anywhere-in-factory-or-warehouse cobot that could work amid humans and normal production flows, work long hours at near maximum payload, quickly pack out a pallet, and then be nimble enough to move on to the next pallet in a hurry.

Two partnered up to take on the world championship of palletizing: World leader in cobot sales, Denmark’s Universal Robots (UR), toting along its newest 6-axis cobot, the UR20, with its 20kg payload capacity and longest reach, together with its partner, Canada’s Robotiq, a specialist palletizing applications and solutions.

It all went down in booth N-4925.

And wouldn’t you know, they pulled it off in grand style!

And wouldn’t you know, they pulled it off in grand style!

Packaging World reported: “The extended reach capability of the UR20 is demonstrated in the Robotiq palletizing system, as it shows how the UR20 can be used to stack items to a height of 1800mm (5.9 feet). With its extended reach, the UR20 can be used to stack across two standard U.S. pallets. With Euro pallets, the UR20 can stack up to 2m in height.”

At long last, the mighty shipping pallet has met its match, and it’s a cobot! A cobot vendor’s machine integrated with Robotiq’s application proved decisive.

The UR/Robotiq partnership typified the two unique takeaways of Pack Expo: Cobots married to integration is the next big thing.

Be sure to look for it at a tradeshow or event near you.

Leave a comment