What’s New in Robotics? 23.09.2022

Posted on Sep 23, 2022 9:08 AM. 8 min read time

News briefs for the week take a look at an all-season yard robot that singlehandedly works leaves, grass, snow, and more, indoor hydroponic farms witness AMRs moving fields of plants, AMRs sprouting cobot arms display versatility, how general adaptability is critical for robot market survival, and soft-tissue travelers slated to deliver drug therapy.

Four-season yardbot

All-around, four-season help with leaves, grass, snow, thatching, and sweeping are what sets the versatile Yarbo apart from all other yard robots on the market. And come this December 2022 (just in time for winter), it’s available for $6,999; but if you pledge $3,699 now, the Yarbo is available for 47% off list price.

Ronkonkoma, NY-based Yarbo has promised even greater versatility in the near future, like the addition of a robotic arm for, as the company says, “picking up packages and scooping up dog poop.”

The “Yarbo Body” is a smart, modular yard robot that accepts three different modules designed for specific, seasonal tasks. According to Gear Patrol, Yarbo packs some impressive specs and features: “The robot requires no perimeter cable and stays in your yard thanks to a mix of navigation technologies, including RTK-GPS and magnetic field navigation. It also incorporates 4G LTE connectivity for app-based control and planning, along with real-time tracking of the device through its high-resolution camera.”

And it’s powerful! Take the snow blower, for instance, the auger/impeller can toss snow up to 40 feet.

And it’s got smarts: Yarbo can sense when it’s finished working or when “its battery is down to 5 percent, at which time it will automatically drive itself to its wireless charging pad to juice up.”

With many single-purpose, robot lawnmowers or snow blowers priced from $1000 to $2500, the Yarbo’s four-season versatility may well make it a market favorite.

Merging AMRs with hydroponics

While most automated mobile robots (AMRs) ramble about inside warehouses and distribution centers moving retail products around, one new breed of AMR is shuttling trays of vegetables, fruits and berries under the skylight roofing of a massive indoor hydroponic farm.

Grover is the farming AMR that San Carlos, CA-based Iron Ox uses to heft 6-foot square pallets of growing, edible greenery.

Iron Ox recently launched Grover, its sleek-looking farming AMR that it describes as “a crop-assisting mobile robot” capable of lifting and moving up to 1,000 pounds of payload. Lots of Grovers are need to constantly move plant beds from germination, to early growth, and then into hydroponic trays (see video).

"We are applying technology to minimize the amount of land, water and energy needed to nourish a growing population," said CEO Brandon Alexander, who grew up picking cotton, potatoes and peanuts on his family's farm in Texas, then became a software engineer who worked on drones and other projects at Google and elsewhere.

The company admits that “Grover makes the massive scale of Iron Ox's facilities possible.” The AMR employs a differential drive system, multiple LiDAR systems, plus upward and forward-facing camera systems.

The company admits that “Grover makes the massive scale of Iron Ox's facilities possible.” The AMR employs a differential drive system, multiple LiDAR systems, plus upward and forward-facing camera systems.

Alexander put together an impressive team of roboticists, plant scientists, and engineers for Iron Ox; and to date, he’s been awarded with over $98 million by investors to scale the company into profitability.

It’s digital farming without soil and much less water, sunlight and overall energy. Iron Ox uses artificial intelligence, machine learning, computer vision, and robotics to grow more with less, “leading to less food waste and reduced greenhouse gas emissions.”

Grover allows Iron Ox to change crops at a moment's notice to meet the needs of nearby grocery stores. Whole Foods, for one, carries Iron Ox product line.

Some AMRs are sprouting arms

Greater robot diversity and versatility are also coming quickly to warehouses and distribution centers as automated mobile robots (AMRs) begin to sprout cobot arms.

Greater robot diversity and versatility are also coming quickly to warehouses and distribution centers as automated mobile robots (AMRs) begin to sprout cobot arms.

Metzingen, Germany-based Neura Robotics is one of many launching a combo of robot arm and AMR base. Neura calls its lineup “cognitive robotic assistants” in describing its new logistics release.

Utilizing Neura’s existing AMR base called MAV that navigates autonomously and can perceive its environment comprehensively, the company added its MAiRA cobot arm, which can see, hear, and feel its environment via integrated augmented intelligence. Atop the AMR base, Neura installed a tower of sliding shelves (see photo) from which the cobot arm either picks products from or places into (see video).

Such product diversity is important to Neura’s future as sales of AMRs are projected, according to Transparency Market Research, to skyrocket to $15.7 billion from 2022 to 2031. Neura, in fact, has just added the highly experienced former KUKA CEO Till Reuter to help its growth and direction.

Versatility: How to survive & thrive in robotics

More and more, it appears that versatility and adaptability are looking like the clarion terms of existence in robotics. If you are Moxi, the service robot from Diligent Robotics, the base it moves on is from Fetch Robotics, its single cobot arm comes courtesy of Kinova Robotics, and its gripper is from Robotiq.

Why reinvent the wheel when what’s needed is already available?

Why reinvent the wheel when what’s needed is already available?

If you are the residents of the Tembok Gede, a district of Surabaya, East Java, Delta, the service robot that disinfects neighborhoods and delivers food during lockdowns, has a head made from a rice cooker, a chest made from an old TV, and a base from a junked toy car chassis.

When you have very little, then innovation and invention may well be what saves the day.

Shenzhen, China-based Reeman Robotics, developer of service robots for the restaurant, hospitality and healthcare/disinfection industries, saw the explosive rise and mesmerizing sales growth of autonomous mobile robots (AMRs), and immediately reacted with its own line of AMRs. The base of its disinfection and restaurant robots was easily adapted into an AMR. And its restaurant robot’s sensors made a nice convergence for visual positioning, indoor navigation, and intelligent obstacle avoidance in warehouses and distribution centers.

What about taking the multi-billions of dollars spent by automakers on autonomous cars (still without any Level 5 or Level 6 autonomy in sight), and adapt it for trackless, people-moving, street trams?

Well, it’s been done. The Chinese Rail Corporation, CRRC, introduced an autonomously guided tram, a significant technology advance for Autonomous Rapid Transit (ART). And it’s in use! Harbin City (northern China) where winter weather is snowy and hazardous, is testing out 19km of the ART system. Check out this amazing video:

VIBEBOT: Micro soft-tissue travelers

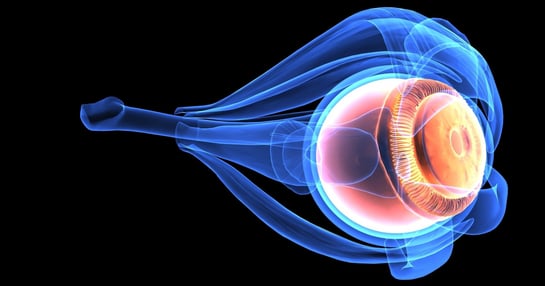

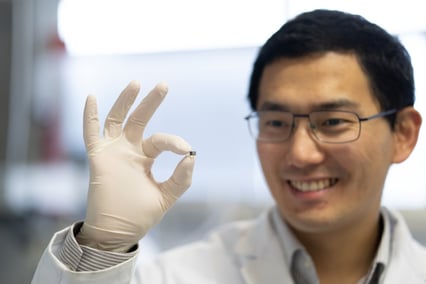

Biomedical engineer and Cyber Valley (Baden-Württemberg) research group leader Dr. Tian Qiu from the Institute of Physical Chemistry at the University of Stuttgart, is a close observer of nature. Specifically, he’s interested in worms.

"We know that worms,” said Qiu, “can penetrate human skin to infect humans. Why can't we build a similar-sized robotic system that can penetrate soft tissue to treat disease… such as targeted drug delivery for tumor therapy?"

"We know that worms,” said Qiu, “can penetrate human skin to infect humans. Why can't we build a similar-sized robotic system that can penetrate soft tissue to treat disease… such as targeted drug delivery for tumor therapy?"

If a micro-size or larger worm can travel through the body’s soft tissue spreading disease, why can’t a mico-robot travel the same way bringing with it drug therapy?

It’s said that minimally-invasive surgery is the future of all surgery, and Tian Qiu’s team is out to prove it with the VIBEBOT soft-tissue micro robot. His team already succeeded in “steering nanorobots through the dense tissue of an eyeball for minimally invasive drug delivery, which had never been achieved before.”

The European Research Council (ERC) has awarded Tian Qiu’s research $1.5 million beginning in early 2023.

Leave a comment