What’s New in Robotics? 22.04.2022

Posted on Apr 22, 2022 11:44 AM. 9 min read time

News briefs for the week take a look at a dual-arm cobot training to uptick dexterity capabilities, virtual reality and cobots partnering on projects, sidewalk delivery robots’ new “carbon emissions” angle, robot vacuums acquiring advanced “dirt-sensing” skills, and Built Robotics “exosystem” refocusing specialization to autonomous excavators only.

Is 57% of a banana good enough?

The next phase in ever-evolving cobot tech looks to be the acquisition of work skills for greater dexterity and accuracy. A million-dollar surgical robot can suture a grape, but can a cobot peel a banana?

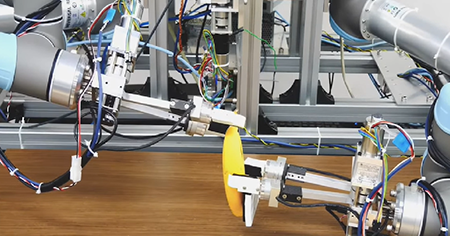

On the surface of things, a dual-arm cobot peeling a banana is an expensive, time-consuming project to take on. Just take a look at the tangle of robotics, wires and end effectors in the accompanying video (see below). Why bother? Especially when the cobot successfully peels the banana only 57% of the time. That’s a failing mark just about anywhere and on anything, and TV media pundits were quick to humorously point out the failing.

On the surface of things, a dual-arm cobot peeling a banana is an expensive, time-consuming project to take on. Just take a look at the tangle of robotics, wires and end effectors in the accompanying video (see below). Why bother? Especially when the cobot successfully peels the banana only 57% of the time. That’s a failing mark just about anywhere and on anything, and TV media pundits were quick to humorously point out the failing.

Well, beneath the surface of this mashup of lab gear, the researchers at the University of Tokyo are demonstrating dexterous manipulation and accuracy in manipulation, both of which are certainly not a strong suit of any industrial robot or cobot today.

See their paper here: Robot peels banana with goal-conditioned dual-action deep imitation learning.

But, if robot/cobot automation is to advance to its next logical step in performing human-like tasks, then mastery of dexterity and accuracy are a must.

UR goes VR: cobot upgrade

Universal Robots (UR) and Virtual Reality working at a jobsite together seem like a natural meetup whose time has come.

UR, having sold over 50,000 cobots worldwide, also has an extensive UR+ program, where it certifies add-on tools for its cobots, like grippers, sensors, software and safety accessories. There are 340 such UR+ kits to date. Virtual Reality is a recent UR+ add-on, which could well see widespread popularity.

Virtual Reality, or simply VR, consists of a VR headset, which offers the wearer a computer-generated environment with scenes and objects that appear to be real, making the user feel they are immersed in their surroundings, like, for example, operating a cobot to do a job.

Virtual Reality, or simply VR, consists of a VR headset, which offers the wearer a computer-generated environment with scenes and objects that appear to be real, making the user feel they are immersed in their surroundings, like, for example, operating a cobot to do a job.

Reading, UK-based Extend Robotics was founded in 2019 by Dr Chang Liu, CEO, chief designer, as well as research associate at Imperial College (London) and University of Southampton.

Of the company’s mission, he says: “We develop human-robot interface software for non-robotic experts to teleoperate and program robotic manipulators remotely for physical tasks.” Emphasis on “non-robotic expert” as operator.

And, amazingly, Extend Robotics has not resorted to high-end, exotic tech; they use “consumer Virtual Reality (VR) technology” to make it easier for individuals to control robotics hardware remotely.

See video of the VR in use, which looks a bit clunky (total cost of arm and VR, including non-UR cobot arm: $14,000). However, the switchover to non-consumer-grade gear will improve the process.

Bottom line: This is a winning tech with massive upside potential.

“Because the banana is deformable, soft, and easily breakable, the robot has to tear its peel while maintaining its body; it requires highly dexterous manipulation skills that consider physical interactions with the target object, which is difficult for rule-based robotics. The banana peeling is a long-horizon task that includes several reaching and peeling subtasks and requires stable manipulation policies.”

This banana-peeling experiment with its 57% success rate was reached after more than 13 hours of training.

While still undergoing more testing, researcher Yasuo Kuniyoshi believes his robot training method can teach robots to do different simple “human” tasks.

Delivery robots on the streets of Santa Monica

Coco, the LA-based delivery robot company, has just begun deliveries with 30 human-piloted robots on the relatively safe sidewalks of Santa Monica, CA.

Two other sidewalk robot delivery companies, Kiwibot and Tortoise, are eyeing Santa Monica as well.

The delivery project, brainstormed and developed by a team of UCLA graduates (formerly known as Cyan Robotics), has partnered with 24 local businesses and completed over 3,800 test deliveries.

The delivery project, brainstormed and developed by a team of UCLA graduates (formerly known as Cyan Robotics), has partnered with 24 local businesses and completed over 3,800 test deliveries.

Coco has just completed a partnership with robot maker, Nashua, NH-based Segway Robotics, which will build 1,200 partially automated, remotely piloted sidewalk robots for Coco’s expansion plans. The first, post-test Coco deliveries launched in Santa Monica in February. An additional 1,200 Coco vehicles will be deployed by May or June 2022, pending potential contracts, according to Sahil Sharma, SVP of vehicles at Coco.

“This is just the beginning of our partnership,” says Tony Ho, Segway VP. “We will stay on the product side of things, and Coco will be the operators. So, it’s a bit similar to the micro-mobility space where we provide the vehicles and hardware and they provide the relationship with the city and the staff and the whole operation behind it.”

“This is just the beginning of our partnership,” says Tony Ho, Segway VP. “We will stay on the product side of things, and Coco will be the operators. So, it’s a bit similar to the micro-mobility space where we provide the vehicles and hardware and they provide the relationship with the city and the staff and the whole operation behind it.”

Coco, born in the living room of UCLA alumni Zach Rash and Brad Squicciarini, came about in the “pandemic-related desire for contact-free delivery,” but now, however, it’s carbon-free selling points are also in play with cities looking to reduce emissions. Coco calculates that its 30 local vehicles have so far reduced over 4,500 lbs. of CO2 and saved 5,000 vehicle miles.

Investors are buying into the company’s vision with $36 million for Coco’s first round of major fundraising.

New “dirt” sensor for robot vacuums

With the global robotic vacuum cleaner market at $11.97 billion in 2021 and projected to grow to $50.65 billion in 2028, any substantial innovation in their cleaning technology could well mean a whopping increase in market share for the lucky innovator.

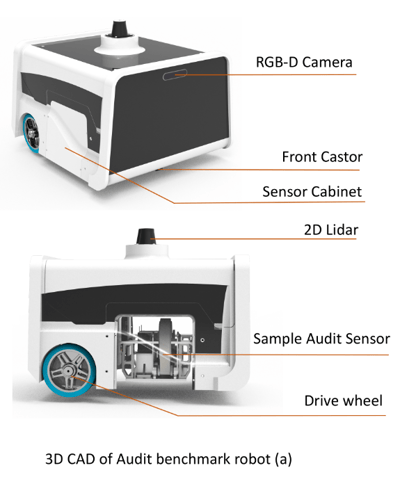

In an industry quick to copy-cat competitor innovations, a new one has just been developed that will cause quite a stir. Researchers at the Singapore University of Technology and Design (SUTD) have developed “a sensor system that helps the robots detect dirt efficiently and prioritize dirtier areas over the less dirty ones.”

In an industry quick to copy-cat competitor innovations, a new one has just been developed that will cause quite a stir. Researchers at the Singapore University of Technology and Design (SUTD) have developed “a sensor system that helps the robots detect dirt efficiently and prioritize dirtier areas over the less dirty ones.”

“The sensor presses a clear adhesive tape onto a surface and compares the cleanliness of the tape before and after pressing. It then assigns a benchmark score, with 0 as the dirtiest and 100 as the cleanest relative to the initial appearance of the tape, and then cleans the area.”

Cleanliness efficiency, according to Consumer Reports’ (CR) Best Robotic Vacuums of 2022, is not only a commonsense consideration when buying a robot vacuum but also one that is of keen interest to CR’s test engineers, i.e. “how well each robotic vacuum removes surface debris on medium-pile carpet and bare floors.”

Although SUTD’s innovation gets high marks for its cleaning prowess, false detections, say the researchers, were also observed upon moving between different floor textures. The tests highlighted the need for further research and improvement of these cleaning robots.

Built Robotics, tightens focus, nets $64M more!

When the pandemic crippled the larger company mission, Built Robotics, developer of autonomous construction equipment, put all of its efforts behind the single most vital construction tool: the trench-digging excavator. And because of that decision, Built Robotics just  scored a $64 million VC investment.

scored a $64 million VC investment.

“You need trenches on almost every type of construction,” says Noah Ready-Campbell, co-founder of the San Francisco-based robotics developer (founded in 2016). “It’s very repetitive, but accuracy matters a lot. You need to make sure that you’re at the right depth; if you go too deep, you risk destabilizing the trench walls and then it’s not safe for the people helping to install the pipelines or cables.”

Built Robotics doesn’t build the entire excavator; Ready-Campbell leaves that to the industry experts like John Deere and Caterpillar. Rather, the company’s expertise sits on the roof of Deere or Caterpiller machines. Ready-Campbell’s company provides an aftermarket add-on it calls the “exosystem,” which it says can add autonomy to “any excavator.” They charge $3,000 per machine per month for the exosystem, plus per-hour usage fees that vary based on location.

Best of all, for a massive autonomous machine roaming a construction site, it’s safe. Ready-Campbell says that after more than 13,000 hours of operation, his exosystem is still accident free.

In a recent interview, he ticks off the formidable safety net Built Robotics has developed from “geofence that automatically shuts the robot down if it leaves a specific area, wireless e-stop buttons around the job site and hardwired e-stops on the excavator itself, and computer vision that constantly scans for people and obstacles around the machine.”

The company’s promo video offers a good overview of the exosystem and its capabilities in action.

Leave a comment