What’s New in Robotics? 19.05.2023

Posted on May 19, 2023 8:16 AM. 8 min read time

News briefs for the week take a look at a live-in robot lost & found for dementia victims, Mitsubishi finally goes in big for AMRs, KUKU and Heller co-develop mobile robot for CNC tool deliveries, spot welding comes of age on the end of a UR cobot, soft robot in a minimally invasive role for epileptic seizures and other neurological disorders.

Robot Lost & Found

Everyone loses things at some time or another. Most times we remember enough to eventually find them. Those with dementia on the other hand have a more difficult or near-impossible chance of recovery.

How about a robot that is an excellent lost & found agent?

How about a robot that is an excellent lost & found agent?

In 2020, estimates of nearly 7 million people ages 65 or older with varying degrees of dementia in the U.S., could well mean lots of missing eyeglasses, medicine bottles, cellphones, wallets, and the dozens of other daily necessities that are small and easily misplaced. Plus, persistent loss of personal things can diminish the quality of life and place burdens on caregivers to recover lost items.

Dr. Ali Ayub and three companions in electrical and computer engineering at Canada’s University of Waterloo (Waterloo, Ontario) were struck by the rapidly rising number of people coping with dementia—9 million Americans could have dementia by 2030 and nearly 12 million by 2040. The three set out to develop a robot helper with skills in lost & found. Strangely enough, it was the first-ever lost & found robot. No one had previously ever attempted to build a robot skilled at finding lost objects.

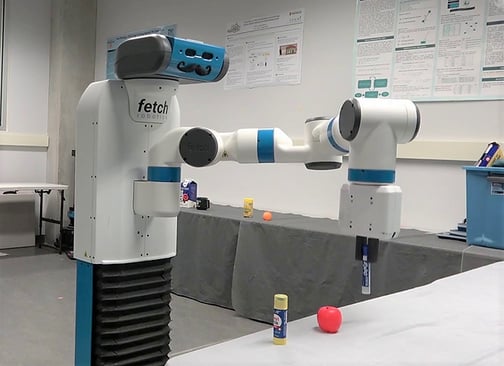

Using a mobile robot manipulator from Fetch Robotics, they created an object-detection algorithm to detect, track and keep a memory log of specific objects in the robot’s camera view using stored video.

With the robot capable of distinguishing one object from another, it can record the time and date when an object enters or leaves its field of view and thus can indicate when and where it last observed the specific object.

Mitsubishi finally goes mobile

Sooner or later every robot vendor without a line of mobile robots (AMRs) feels the pressure to go “mobil” or risk getting left behind in the fast-moving global warehouse and factory automation movement.

With a spate of acquisitions and mergers going on around them in the mobile robot industry, Mitsubishi Electric has just joined the club with a move to rectify the missing AMRs in its product line.

With a spate of acquisitions and mergers going on around them in the mobile robot industry, Mitsubishi Electric has just joined the club with a move to rectify the missing AMRs in its product line.

Canada’s Kitchener, Ontario-based Clearpath Robotics, parent company of OTTO Motors (OTTO launched in 2015) has entered into an agreement to supply Mitsubishi Electric with its OTTO self-driving vehicles to transport materials around warehouses and manufacturing facilities.

As OTTO puts it on its website: “Smart factories begin with smart AMRs and OTTO Autonomous Mobile Robots (AMRs) automate common material handling tasks, big and small, to help manufacturers tackle labor shortages, scale their business, and outperform the competition.”

This is exactly what Mitsubishi says it needs, writing in a recent press release: “Mitsubishi Electric aims to strengthen its support for complete factory optimization and automation by utilizing AMR systems and continue to contribute to the further development of manufacturing automation.”

New robot challenge: “Enhanced Automation”

Low quantities, high complexity – and as fast as possible seem to be the watchwords for most anything manufactured these days. As such, manufacturers are constantly on the lookout for any aspect of production that can be further automated or produced more speedily.

To that point, robot builder KUKA and CNC builder Heller have joined together to automate the previously manual process of loading and unloading of machine tools into a CNC machine. In a project said to meet the “challenges of quality, volume, and speed,” plus solve the shortage of skilled workers, KUKA and Heller have developed what they call “enhancing automation” or the further automation of an already automated task or process. Specifically, delivering a set of requested machine tools to a CNC machine to perform a specific job, and upon completion of the job, retrieving the tools for delivery to yet another CNC machine in need.

To that point, robot builder KUKA and CNC builder Heller have joined together to automate the previously manual process of loading and unloading of machine tools into a CNC machine. In a project said to meet the “challenges of quality, volume, and speed,” plus solve the shortage of skilled workers, KUKA and Heller have developed what they call “enhancing automation” or the further automation of an already automated task or process. Specifically, delivering a set of requested machine tools to a CNC machine to perform a specific job, and upon completion of the job, retrieving the tools for delivery to yet another CNC machine in need.

As KUKA saw it: “While automation solutions are already well advanced in such areas as palletizing, handling or assembly tasks, tool automation – the flexible and automated loading and unloading of machines with tools – is still in its infancy.”

There are tens of thousands of CNC machines (computer numerical control machines) in the world that are part of a global market projected to reach $132.93 billion by 2030. KUKA and Heller may have just created a very popular new business with their new invention, which is essentially a mobile robot and articulated arm. The mobile tool system can also spot damaged tools, and then discard and replace them.

Universal Robots debuts spot-welding cobot

Until now, the lightweight cobot was unable to execute spot welds because of the weight of the welding gun and the complexity of the welds. Formerly, welding technologies such as MIG welding have become popular choices for cobots while spot welding remained prohibitive.

California-based Pro Spot International has come up with a solution. The company claims that its i5s resistance spot welder for use with a Universal Robots cobot will deliver up to three times more manufacturing capacity than manual welding.

“We’ve married the most sophisticated spot welder in the world with the most sophisticated cobot technology to deliver a solution for industrial spot welding that increases productivity, safety, consistency and job reliability,” says Pro Spot Automation’s chief engineer, Bob Hamilton. “It’s the forefront of tomorrow, right here today.”

“We’ve married the most sophisticated spot welder in the world with the most sophisticated cobot technology to deliver a solution for industrial spot welding that increases productivity, safety, consistency and job reliability,” says Pro Spot Automation’s chief engineer, Bob Hamilton. “It’s the forefront of tomorrow, right here today.”

The global spot-welding market in 2022 was $3 billion and growing at 3% CAGR. However, when peripherals like hoses, tanks, and welding guns, etc., are included, the market for 2026 is forecast as $11 billion.

According to Pro Spot and Universal Robots, these “next generation” automated cobot spot welders can “sense material thicknesses and resistance and adjust its weld profiles automatically. It also captures data about each weld that can be used for quality control, traceability, and job repeatability.”

Wi-Fi connectivity of cobot spot welders allows for instant updates, data exports, and the ability to email welding logs for performance reporting.

First showing of this new-generation welder is at Automate 2023, May 22-25, in Detroit.

Soft robot sensor under the cranium

It may look like an alien creature, but if you’re suffering from epileptic seizures or other neurological disorders, it’s a godsend. And that it is placed under the cranium through a minimally invasive opening, makes all other brain monitors look gargantuan in comparison.

The concept, says Stéphanie Lacour at the Swiss Federal Institute of Technology in Lausanne (Switzerland), is a new approach for placing electrodes on the brain’s surface “compared with the traditional method, in which surgeons cut a large hole in the skull the size of the fully extended device. There’s actually a really large surface area that you can reach without doing a large craniotomy,” she adds.

The concept, says Stéphanie Lacour at the Swiss Federal Institute of Technology in Lausanne (Switzerland), is a new approach for placing electrodes on the brain’s surface “compared with the traditional method, in which surgeons cut a large hole in the skull the size of the fully extended device. There’s actually a really large surface area that you can reach without doing a large craniotomy,” she adds.

The soft robot, about 2 centimeters long—and when fully extended covers a diameter of 4 centimeters (0.78 inch to 1.50 inches)—has six legs made from a flexible silicone polymer. The legs resemble curved flower petals radiating around a central body. Each leg contains electrodes for monitoring brain activity.

“Future versions,” says Lacour, could be bidirectional, not only sensing brain activity but also stimulating it. “That might allow the device to stop seizure activity before it begins, stimulate brain areas damaged by stroke or act as a brain-machine interface to allow people to control devices.”

Leave a comment