What's a Digital Twin and How It Helps You Save Money

Posted on Feb 07, 2018 7:00 AM. 5 min read time

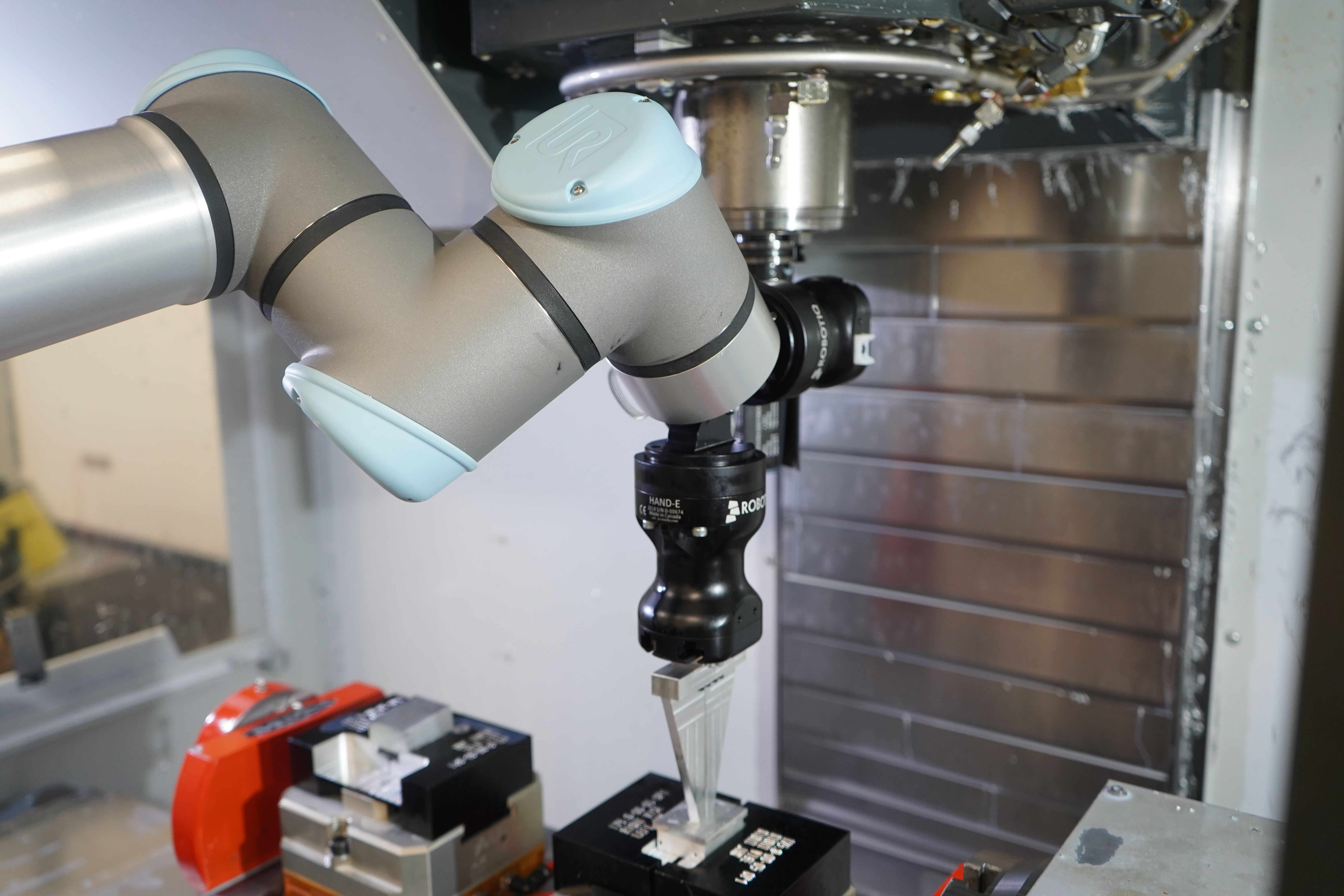

A digital twin is, by definition, a virtual replica of a physical asset. But it is actually a lot more than that. It is a combination of IoT, machine learning and AI put together to build a replica of your physical machine and make it analyze and or predict what are the impacts of actions on that machine. It is a trending topic and it touches robotics in different aspects. And honestly it is pretty cool.

.jpg?width=640&name=_MG_6825%20(2).jpg)

Insights is a robot digital twin

A digital twin is basically just the continuity of the big data trend. We are currently in an era where data is one of the most important resources a company can get, either for its users (social networks), its machines (Insights), its mountain bike trails (Trailforks) or even its almond fields (Hortau). In fact, the goal, for now, is to have as much data as possible to detect trends or to react to a given situation.

It doesn't matter if you are managing a robot or a mountain bike trail network. You are certainly observing trends. But if you don’t have data to back you, it's hard to differentiate perceptions from actual facts. If you see a particular use on a certain trail or robot, you will most likely put more attention on this particular unit. You might also want to perform preventive maintenance more frequently because you wouldn’t want that unit to go down since it is your best seller, or because it is critical to other units around.

For now, what we generally see in the industry is reactive and proactive solutions, but a digital twin is a lot more than that. In fact, once we will have gathered enough data and experiences, and when the size of the sample will be large enough, we will be able to have predictive and eventually prescriptive solutions. Just like in the next video.

And that is a digital twin. It's not just simply a robot or a turbine that acts like the actual machine that you operate. It is actually the summation of all past experiences and previous data joined with the present utilization of your physical machine put into a digital representation.

If we bring it down a notch, the digital twin will be able to predict when a certain failure or event will happen according to its past experiences and will also know how not to recreate a failure or a certain type of event.

This seems fine, but how could this help me?

Have you ever owned a car? Do you know what is the wear of your tires, brakes, engine and transmission until you go to the garage? No, you don’t. Well imagine that with the utilization you are doing of your car, its digital twin could provide you with reports of your car but also can recommend its maintenance. Wouldn't that be nice? For example, Tesla has all its cars connected to the cloud, and I am assuming it can log all sensor data for all cars. They are certainly putting together all of this data in order to build an accurate representation of their cars, and predict what it will happen if you do a certain action. And I am not just talking about maintenance here, I am talking about the deeper decisions that the car can make.

For example, according to the weather forecast, the wear of your brakes and the banking of the next curve, there are very few chances you would be able to negotiate it at a given speed without using traction control. The autopilot would therefore bring it down a notch in order to save the use of certain sensors/mechanism.

How can I save money by developing my robot's digital twin?

Well, for now, let’s be honest: it will cost you more to gather data than not doing it. And you will be able to do very few things with such information. On the other hand, you should have started to gather data yesterday . Either it is for your own utilization (performance, efficiency, cycle time) or to put all this data together and do something with it (I don’t know what, exactly).

Have you ever lost production time because your unattended cell was down? Insights allows you to create custom events. Any stop in production will send a notification so that you can get back to production faster. You can also download a log of events for further analysis.

A software like Insights allows you to optimize your cycle time, reduce the downtimes via instant alerts on your cell phone, but it also gives you the pulse of your production in terms of units produced in one day for example. At the end of the day, you save money right? You have to pay a certain amount of money to install the license, but if you can optimize your program to be 5% faster, allowing you to produce more in a day, your investment will be repaid instantly.

That's it for now, but if you look at data that a software like Insights is putting together, it is an opportunity to have robots that can optimize themselves or even make decisions based on their previous experiences. One day, we will reach a point where the robot will ask you to optimize its paths or ask if it is allowed to perform a particular actions in a given situation. We will then be in presence of a digital twin. But we are far from being able to do that.

For now, keep logging your data and who knows what you will be able to do with it. As a production engineer, I totally recommend you to start now, to at least have the heartbeat of your production. Only then will you be able to determine trends and eventually be able to take action to either optimize your production or avoid having a breakdown, and eventually save money.

Leave a comment