Self-Driving Vehicles Quick to Replace AGVs

Posted on May 30, 2016 7:00 AM. 4 min read time

Automated Guided Vehicle (AGV) technology dates back to the 1950s, and surprisingly hasn’t changed much since. With artificial intelligence technologies leaving AGVs in the dust, self-driving vehicles will soon take the main stage in manufacturing, allowing for more productivity while achieving lower risk. With factory settings becoming increasingly automated, and the various new manufacturing robots out there that work alongside humans with very little risk, it’s time for factory floor transportation to catch up – and it is.

What Exactly is an AGV?

Automated Guided Vehicles, or AGVs as they are more commonly known, were first introduced into manufacturing in the 1950s. With the literally tons of materials typically moving across factory floors, AGVs have long made transportation along the assembly line more sustainable and less risky. That said, the AGV technology has advanced little over the nearly 70 years that it has been in use. Used in mostly every industry out there from paper to metals, these automated vehicles typically push or tow loads. Parrett Electronics was the first company to introduce this amazing technology into the marketplace, and the first AGVs were guided by wires on the floor or hanging from the ceiling. Over time they have evolved to follow magnetic tape on the ground, and then UV markers using lasers. These generations of AGVs, however, still lacked any true autonomy, and have always been destined to follow fixed patterns.

Why Self-Driving Vehicles?

Self-driving vehicles are the latest iteration of the AGV idea. While many people would still call them AGVs when used in a manufacturing setting, this technology so much more advanced that it’s hard to lump them in the same category. Self-driving vehicles offer many benefits to the factory floor that AGVs cannot. Stuck on a predetermined track without any ability to leave it, AGVs are prone to collisions, and cannot adapt to new circumstances. Self-driving vehicles, with intelligence on board, can auto correct when they recognize risk, and redirect their path at any moment. Being more self-sufficient, self-driving vehicles are truly collaborative, requiring very little from their human counterparts while accomplishing more. On the other hand, AGVs still require significant human intervention, and usually work alongside forklifts and other man-driven vehicles required to complete tasks that they are unable to do. Self-driving vehicles, however, could completely eliminate humans from any aspect of factory floor transportation, while reducing the risk of moving materials throughout the manufacturing process.

How Can Self-Driving Vehicles Improve Manufacturing?

As a manufacturing company your main goals are always to increase productivity while lowering cost and risk. Self-driving vehicles accomplish these three goals on many levels. Able to work around the clock at no expense, your labor will become more reliable, and completely free. People need breaks, and their margin of error is typically higher than a computer, while a self-driving vehicle can work without ceasing and deliver great results. While there is always that initial investment to consider, you’ll quickly notice a return on your investment on the books. With this new technology in place, it makes even more sense to hand off the monotonous task of material transportation to the machines more suited to do it.

OTTO and Amazon

Before self-driving cars hit the streets, what we are seeing now is this technology being used indoors. Factory floors, especially in distribution centers are often set up like micro cities. Organized on a grid, this model helps keep better track of inventory and expedite orders more efficiently. Without the outdoor elements to consider, or the density of an international metro like New York City or Montreal, they are the perfect place to put these new technologies to the test.

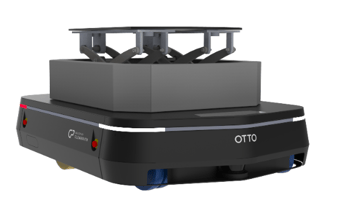

Clearpath Robotics released their OTTO self-driving manufacturing robot last year. OTTO is equipped to move up to 3300 pounds at 4.5 mph, and will always adjust to take the most optimal paths around your factory floor. With the ability to avoid possible collision, this self-driving vehicle will actually reduce the risk of your manufacturing facility by taking the weight of material transportation off the backs of your employees, and into the hands of trusted workers. Recently adopted by a GE Healthcare facility, the director of Repair Operations there, Patricio Espinosa, stated that “Clearpath’s OTTO self-driving vehicle and intelligent technology will help us serve our customers with speed, flexibility and accuracy, and gives us the ability to scale our operations going forward.”

Kiva, bought by Amazon and used solely in their distribution warehouses, is another self-driving vehicle used in factory transportation. These robots are called upon by the workers to bring them inventoried bins in which they will find the order they are fulfilling and then sent out for shipment. As soon as you hit “confirm purchase” on your Amazon Prime, there’s a robot in line to find your product and gives it to the person in charge of sending it out the door.

With these new technologies now readily available, it is only a matter of time before traditional AGVs are piling up in storage units around the world. Self-driving vehicles are no longer the future, but the very prescient present starting with the often hidden worlds of warehouses and factories.

Leave a comment