Will Robots Lower Your Cellphone Price Point?

Posted on Aug 31, 2015 2:12 PM. 5 min read time

Robots are made to do redundant tasks because of their endurance. What is the market that has the most robotization: the automotive industry. The reason is that a car is a large piece of metal that requires a lot of work and the production has to be done at a very fast rate. Since a car has to be as cheap as possible for the end user, while it is still an expensive product, the manufacturer has to optimize their production line and design to give more things to the end user without increasing the price or the production time. But what about cellphones and other electronic devices, doesn’t the same principle apply?

In fact, personal electronic devices (PEDs) are getting smaller, faster, have more functionalities and their price is still going down slightly. The main reason for this price drop is basically due to manufacturing processes that are getting faster and faster. However, there is a tipping point where you cannot make your production go any faster. Especially when workers are working too many hours per days and have very redundant jobs. So one of the solutions to keep up the production rate is basically to get into automation.

China is investing

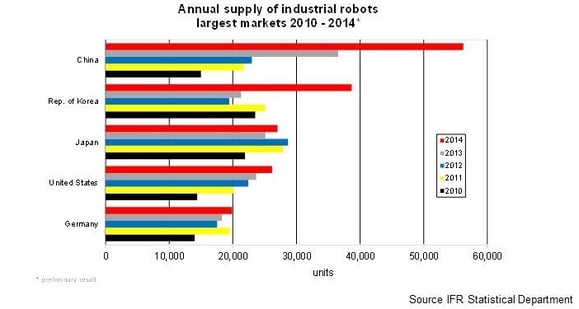

In 2014 worldwide robot sales were about 240,000 units with about 56,000 attributed to China. Considering that robots are mostly used in automotive industries (approx. 40% of the total sales) and that China is not a major automotive producer, you can suspect that a lot of these robot must be going into electronics manufacturing. Which is not a bad thing right. I mean China is the largest electronics producer and to be able to keep up with the fast (and always growing) cellphone market, you just don't have the choice not to automate.

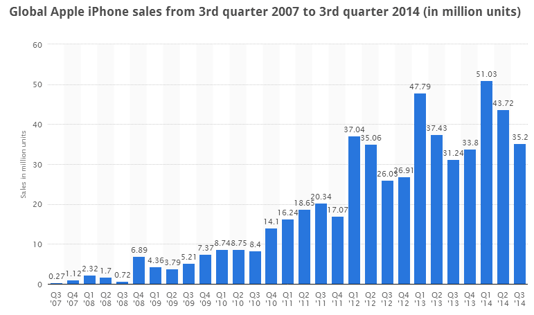

Table 1: Global Apple IPhone sales in million units. Source: Quora.com

Following these trends, you can see an important increase in robot sales in China. In fact according to the International Federation of Robotics, IFR Statistical Department, China has bought 160% more robots in 2014 than it did in 2013, which makes them the largest buyer of robots on the planet.

Considering that other countries are not into major electronics manufacturing, but are acting more around the automotive business, it is quite impressive to see China growing at such rate over the past few years.

And then I know what some people might think: nobody will work in China anymore! Well, I am not saying that robots will not displace some jobs here and there, but the important statistic to understand is that China is the lowest ranked in robot density of the 5 countries listed above. The average worldwide robot density is 62 robots per 10,000 employees, while China has a robot density of 30. This means that there are plenty of other manual manufacturing jobs in China and that this massive robot acquisition is not going to affect the country’s overall unemployment rate.

Electronic specific robots

The statistics do not specify which robots are used to achieve manipulation with electronics. However, the industry seems to be focusing on this part of the market by releasing electronic specific robots. The recent ABB Yumi and Universal Robots UR3 have a very low payload and are made for lightweight assembly or electronic handling. With a tiny 0.5 kg payload per arm Yumi is definitely made for electronics. Its ability to do pick and place operations allows the worker to focus on very dexterous tasks, while letting the robot to handle the parts.

Why are we only beginning to automate electronic assembly?

Robots used to be big, powerful and not really space efficient. Well, now this is all different. With robots that can fit in a workers space and that can work around workers without harming them, it is getting more and more interesting to use a robot to pick a cellphone from one conveyor to move it to another station, then be worked on by a human worker. With the addition of force sensing and all the other enhanced technology, robots are getting more precise not because of their accuracy, but because they can feel and monitor their environment. They can detect if they are at the right spot in the fixture. This was absolutely impossible 5 years ago.

Take a look at the use of a collaborative robot (Universal Robots) and a Force Torque Sensor to assemble batteries in a cellphone case. This demonstrates the fact that robots can comply with different situation, but also demonstrates that the technology is not quite there yet. In fact, this video was shot in a lab that is developing such an application. It is still not mature enough for industry, however, at the rate that technology is growing, I won't be surprise to see these applications on the production line in a couple of months.

Finally, what I am trying to say (after all) is since China is focusing on what they knows best (electronic devices) it let other countries focus on thier forces. Let Japan manufacture robots, let Republic of south Korea and Germany produce cars. By focusing on what you are good at and enhance your process, your price point can go down and you can (enventually) sell more product. All of this manufacturing process using robots and increases national productivity and eventually increases national worth. Robot for the win! If you are interessted in doing light application using a robot you can take a look at our eBook and comparative chart on Collaborative Robots by clicking on the link below.

Leave a comment