Robotiq Devices at the Amazon Picking Challenge

Posted on May 20, 2015 2:50 PM. 4 min read time

With the upcoming Amazon Picking Challenge, we can now have a behind the scenes view of what is going on with the teams. Even if it seems simple, picking an object out of a bin is quite a complex task for a robot. Now add trying to grab various objects of different shapes, sizes, textures and orientations and you multiply the complexity factor.

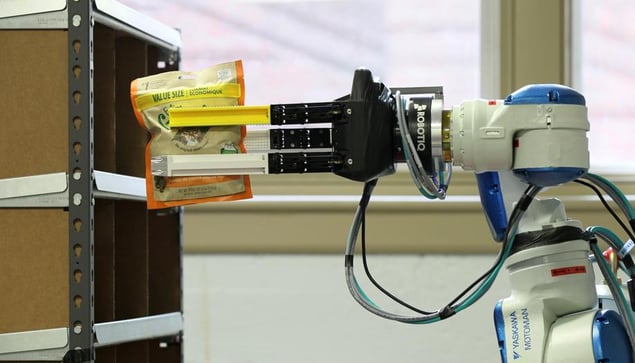

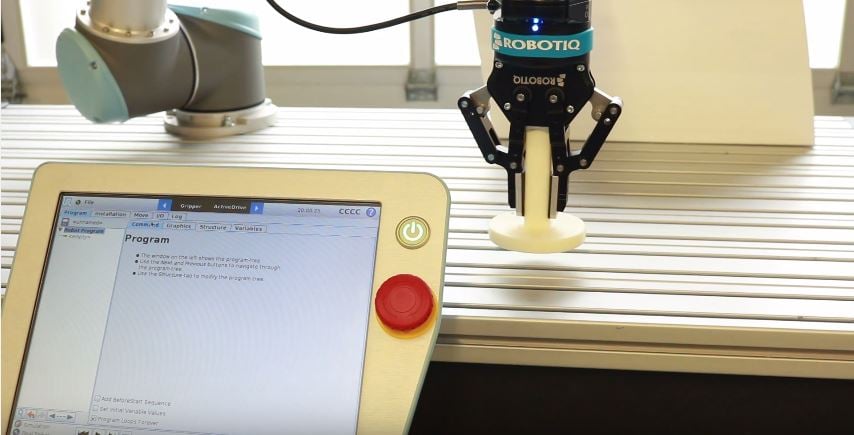

The team from WPI (Worcester Polytechnic Institute) is trying to sort out the different issues that they will be facing in a few days at the ICRA 2015 challenge. With a bunch of different devices and techniques they are trying to resolve the main problem addressed in this challenge: How best to grasp a bunch of different objects in a bin and carry them to another bin? Quite simple right? Well, it is not that simple.

Integrating: robot arms, 3D vision, grippers, force-torque sensors and all the limitations incorporated in all these devices makes the problem more complex than it really is. As Scott Kirsner from Beta Boston says: “If you entered a 5-year-old who could read the order list, she’d be stiff competition for the robots’’.

However, even if the technology is not quite there yet, it is getting there pretty fast. The teams (mostly from Universities) are using all their knowledge to make the robots work properly for the complex situation which is presented to them. The context of the Amazon Picking Challenge is to introduce robots into warehouses at a very specific spot. In fact, you should first understand that the inventory at Amazon is not fixed on their shelves, it is constantly in motion on shelves moved by other robots. Almost like ants moving in their nest, the Kiva robots bring each shelf to a specific spot in the warehouse where the identified item is handled by a worker and putted on a conveyor belt.

At this step of the operation, you should also know that the worker is not making any kind of decision, s/he simply grab the object indicated by a light signal and transfers it to the conveyor belt. So instead of asking a human worker to stand at a fixed spot and do this mind numbing, overly repetitive motion, Amazon thought it was more logical to use robots for this part of the process. So this is where the different teams and solutions of the Amazon Picking Challenge are coming together.

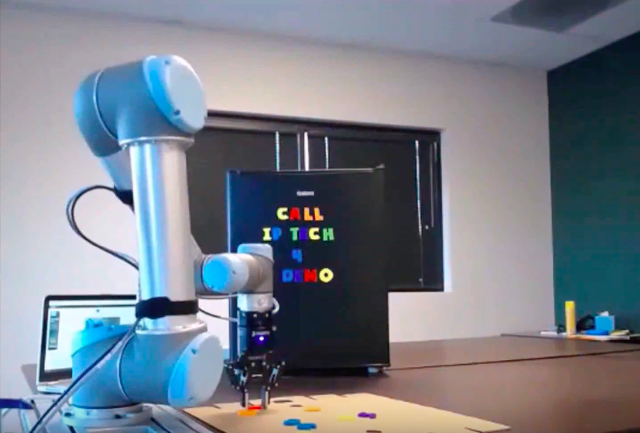

To make things easier for the teams, Amazon has selected a list of 24 items with different geometries and textures that will provide different degrees of difficulty. They might be hard to detect by vision or hard to grasp, but their main goal is to encourage an advance in science and of course, build solutions that are suitable for their warehouses. So the teams are building complete robot cells that can autonomously detect, grasp and move the objects.

Replacing a Worker?

“Just look at the tasks these people are doing. A laser points to the item and a red light blinks to show you which item to pick, then you put it into the box. What you see is a person acting as a robot.” - Frank Tobe, The Robot Report

Tobe suggests that these workers would be wise to take advantage of Amazon’s 95 percent tuition reimbursement to advance their education and skills. “Those low-skilled jobs are going to be falling off the grid,” Tobe predicts. This is the reality for some low skilled workers, but this shouldn’t stop progress, as who really wants to do the physically demanding, mind numbing repetitive work a robot could do all day.

On the other hand, Amazon is planning to open new warehouses in Fall River and Freetown over the following year. These two warehouses could potentially create 500 jobs that would last 5 years. So, there is no absolute loss in terms of jobs and many of these jobs will not be the minimum wage kind.

The Challenge

The challenge will be held at ICRA 2015 in Seattle, WA from May 26th to 28th. It includes a total of $26,000 in prizes. We will have a Robotiq representative at the event, so we hope to keep you informed on the developments of the competition.

If you are interested in exploring some of the different research projects that have been worked on involving our 3-Finger Gripper, click on the link below.

Leave a comment