Boost Your CNC Productivity with Automated Part Feeding

Posted on Nov 15, 2023 8:57 AM. 8 min read time

Keep chips flying!

Machine shops typically operate CNC machines at only 60-70% capacity, and there are multiple reasons behind this. The lack of skilled operators is one factor. The manufacturing industry faces major challenges, including high job turnover rates of up to 50% and a projected labor deficit of over 10% by 2030. The younger generation's disinterest in repetitive and low-skilled jobs contributes to this deficit. Finding one good candidate is difficult, but finding a second candidate for a second shift is even more challenging. Finding a candidate willing to work night shifts feels almost like a miracle. But in today's uncertain economic climate, with rising interest rates and global instability, wasting 30% of runtime is simply unaffordable.

Retrieve the remaining 30% promptly with a robotic machine tending solution

By utilizing a robot to supply parts consistently, the runtime of machines can be boosted by a minimum of 15%. This approach not only ensures more reliable loading and unloading procedures but also eliminates the risk of human errors commonly associated with repetitive and monotonous tasks.

Compared to manual tending, utilizing a CNC machine with a robotic system is four times more cost-effective. The Robotiq Machine Tending Solution enables machine shops to rapidly recoup their investment in CNC machines.

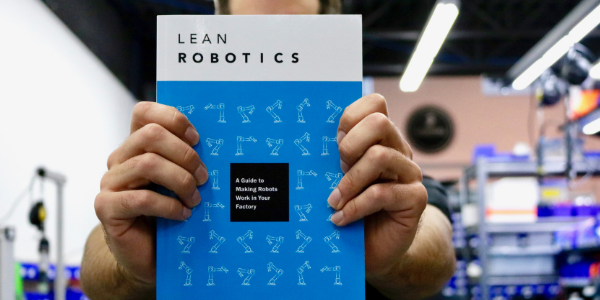

Meet the Machine Tending Solution

Robotiq redefines automated part feeding with a non-invasive and streamlined collaborative robot solution that empowers people, boosts productivity, and promotes adaptability, all while fostering a swift and cost-effective deployment.

The Robotiq Machine Tending Solution replicates the actions of a human operator on a CNC machine. The system monitors the machine's status via signal lights, opens and closes the chuck with a foot pedal, picks and aligns parts, and starts the machine with the press of a button. The robot interfaces with the machine just like an operator would but without requiring communication cards, expensive wiring, custom programming, or permanent modifications. The solution doesn’t alter the CNC programs; external modules manage the communication between the CNC machine and the robot.

-2.png?width=500&height=256&name=Machine%20Tending%20Solution_full%20cell_01%20(1)-2.png)

This non-invasive method has multiple benefits.

- Compatible with any CNC machine model, brand, or age, allowing manufacturers to effectively automate their production floor.

- Standardized technology that facilitates knowledge transfer and training.

- Deployment within a few hours. There is no production downtime.

- Non-invasive solution means you don't need to hack your CNC and risk voiding its warranty.

- No complex programming is required. Avoid reliance on system integrators and ensure continuous production uptime even during changeovers.

- Seamless transition from automated to manual part feeding to easily manage small quantities.

Maintain uptime with streamlined configurations

Machine tending applications are complex. The motion required is intricate in order to avoid collisions with the sensitive machining equipment. This complexity makes it difficult for both beginners and experienced users to program and redeploy quickly during changeovers. That is why the Robotiq Machine Tending Copilot software does not require programming skills. Configurations are grouped under assistant tools designed to simplify setups and guide users through a sequence of steps. The configurations include images for visual guidance and to support the development of employee expertise and autonomy.

Program Generator Feature

The Copilot software takes the complexity out by generating program templates tailored to the CNC machine type and gripper configurations. With a decade of expertise in machine tending applications, Robotiq's engineering team has developed comprehensive features to automate the task list creation process in machine tending programs. This feature removes the need for users to think about the logic and list of steps behind a machine program. After the program is automatically generated, the user simply needs to follow the process and fill in the required information.

Select the CNC machine type and gripper configuration to effortlessly unlock a program template.

Smart Move Feature

Teaching trajectories to the robot is quick with the Robotiq Machine Tending Smart Move feature. Teach up to 10 waypoints and set a safe "fly zone" by manually moving the robot to each position. Generating optimized robot motions without collisions is done in minutes and without the need for programming. Non-robot experts can effortlessly and confidently teach the robot and build reliable programs.

Manually move the robot to the desired position..png?width=603&height=393&name=photo%20(2).png)

|

New to the Robotiq Machine Tending Solution |

Empower your workforce

Relying on skilled operators to feed parts to machines fails to optimize their unique strengths. Research shows that 83% of workers prefer employers who provide modern devices like robots to enhance their tasks. The Robotiq Machine Tending Solution has made automation accessible to businesses of all sizes, overturning the belief that it is too complicated. By redirecting skilled workers to more strategic tasks, machine shop owners can gain important competitive advantages, particularly when talent retention is a global challenge.

See how Fusion OEM empowered their workforce and increased their production by 50% with our Machine Tending Solution.

Do not let a 30% production runtime increase go to waste. Discover the potential of Robotiq's Machine Tending Solution in bridging the gap in workforce availability, especially for night shifts and repetitive tasks. Embrace this opportunity to maximize your production runtime and stay ahead in the current economic landscape. Click here to transform your operations!

Leave a comment