Choosing the Right Robot Gripper for your Process

Posted on Sep 10, 2014 5:43 AM. 4 min read time

In the design of your robotic cell, once you have figure out which gripper would best suit your parts you then have to analyze the actual process. Even if the robotic tooling is able to grasp the part, can it do something useful with it after is has the part? Some applications require exact tool specifications and you should consider them in your analysis. The question you should ask yourself is:

What will my robot need to do once it picks the part and how will this influence my choice of robot gripper?

Cycle Time

Probably one of the most limiting aspect for a gripper is cycle time. Most industrial applications require a fast cycle time to achieve a certain production rate. So a fast/reliable gripper would be best for such applications. Although, if you are looking at applications for collaborative robots for example, the cycle time might be able to be a little slower due to safety requirements. This means that a fast gripper with short cycle time is not a necessity.

Required Repeatability

This aspect can be limited for some operations, but has to be negotiated for others. Since the pick-up operation can (most of the time) have a larger tolerance (pre-ordered layout, belt, etc.), the object drop tolerance/repeatability has to be precise. For example, if the robot has to fit a shaft in a CNC machine chuck, you want it to be highly repeatable to make sure the part is easily entering in the chuck. The opposite case is if the robot is doing pick and place in a cardboard layout, the repeatability can be a slightly less precise if it is not critical to place the part in the same 1/10 millimeter space.

Make sure to buy a gripper that has a required repeatability that fits your application(s). It can be good to have robotic tooling that can achieve an extremely good repeatability, but if your application doesn't need such precision, you will probably pay too 'much ado about nothing'.

Environment

Dirty, hot, flying metal chips, irregular heating sources, welding sparks, medical environments, agricultural environments, explosive environment are all aspects that have to be considered while choosing your gripper. Most of the end effector manufacturers will give an IP rating to their products. This will give you a good idea of where to use your gripper.

Motions

Motions for the robot may seem to be a totally separate aspect from the grasping itself, but in fact you should consider the motions and more specifically the accelerations of the robot in your design. If the robot is accelerating at an outrageous rate to achieve a certain cycle time, your gripper should consequently still be able to retain the object. You don't want to slow down the process because the robotic tooling you're using cannot grasp objects hard enough. Some gripper manufacturers are offering personalized fingertip pads or fingertip options to suit your applications. Options such as rubber fingertips can be good to securely grip a part and make sure it doesn't slip while the robot is moving.

Pick/Drop Layout

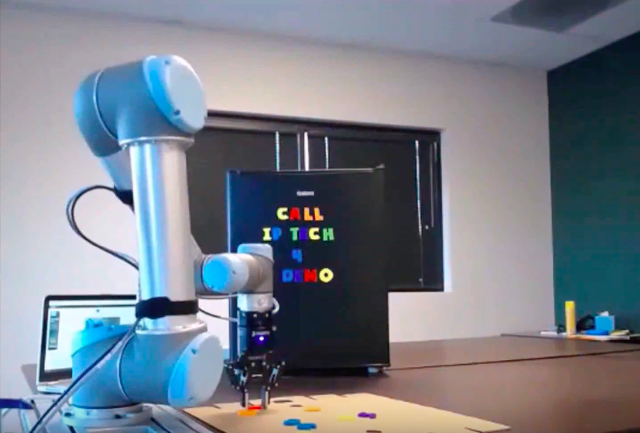

Place it on a conveyor? Insert it into a machine? Assemble it with other parts?

The place where the parts are to be taken or drop is really important in the choice of the gripper. Consider the robot's surrounding very carefully. A 3D CAD or a simulation can help you figure out if the gripper is too big for its surroundings. Imagine buying a whole robotic cell only to realize that the parts are too far away and cannot be securely grasped by the gripper.

Hopefully, this has given you a better idea of what to look for when choosing a gripper. Remember to carefully analyze your process(es) before starting the buying process and you can always contact a local systems integrator for advice. If you are looking for a machine tending application, you take a look at our past article on ''What you need to look for in Machine Tending Automation'' or have a look at the different advantages for adaptive grippers in the link below.

Leave a comment