Robotiq Robot Hands in Research Applications

Posted on Sep 05, 2014 8:48 AM. 4 min read time

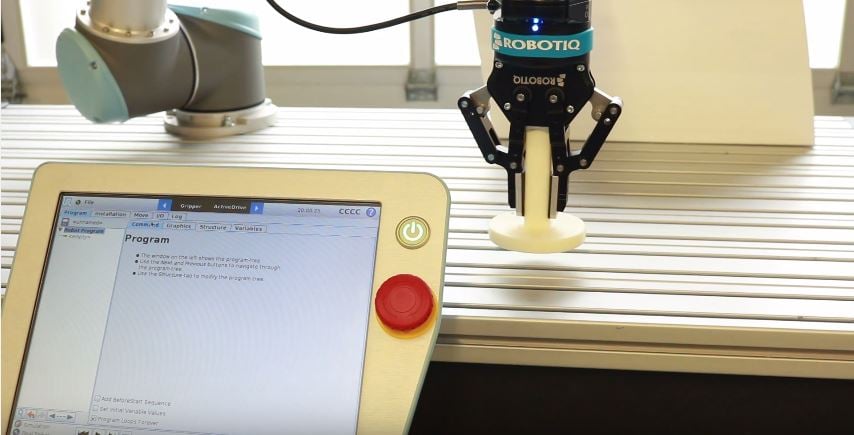

The technology behind the Robotiq 3-Finger Adaptive Gripper was developed in the robotics laboratory of Laval University, which was looking to use robotics in dangerous and unstructured environments. Today, several laboratories around the world are using our hand to push the limits of their robotics projects. Here are some noteworthy projects that we're particularly proud of where our hand is being used.

- DARPA Robotics Challenge

The DARPA Robotics Challenge is a competition hosted by the US Department of Defense where several robotic research departments are competing in a variety of tests. The context is to develop the best humanoid robot that can perform in conditions similar to a natural or human disaster. The robot designed by the different teams has to be really flexible because the nature of the challenge is very diverse. From opening a door or valve to driving a car or climbing steps, the robots have to be able to face any situation. This is one of the reasons why 4 of the top placing teams have chosen to use the 3-Finger Adaptive Gripper for the competition.

The final stage of the challenge will be hosted in California on June 5 & 6, 2015. We are really looking forward to seeing our electric gripper perform with the teams at this competition.

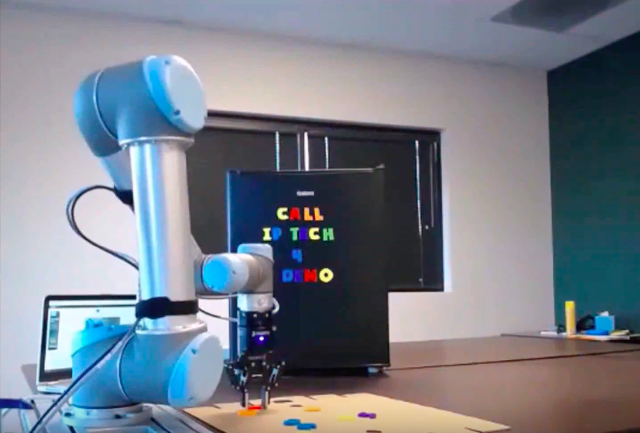

- RoboGasInspector

The project goal is to automate infrastructure inspection in particular at refinery and gas plants. The autonomous vehicle can run around the plant and detect gas leaks and other problems. By using a Universal Robots' robotic arm paired with a Robotiq 3-Finger Adaptive Gripper, the robot can execute different tasks. In fact, operation such as opening and closing valves or moving diverse objects can be executed without having humans involve in potentially risky situations. With the presence of gas or other dangerous substances, the robot can do dirty and dangerous jobs while being controlled by operators in a monitoring center miles away.

- Clearpath Robotics

Another autonomous vehicle is using our electric gripper, the CEAR Mobile Manipulator is an agriculturally focused vehicle. In fact, the vehicle is designed to execute different tasks that can be done in an agricultural environment, such as patrolling orchards and pile assembly/disassembly. The project is using a 3-Finger Adaptive Gripper for its flexibility and ease in adapting to different geometries, as well as its ability to exert controlled presure on the items being manipulated.

- CHARM Project

The Collaborative, Human-Focused, Assistive Robotics for Manufacturing project is the next level of Human-Robot collaboration. In fact, the robot is programmed to react to human gestures and positions. The project is in collaboration with GM Canada and is focused on automotive assembly line optimization. With this project the worker can use his body to request assistance from the robot. For example, a certain arm gesture would be interpreted by the robot as a request for a part from the robot. Then the robot will bring the part to the operator and wait for the next command from the operator. All the operations are done using a 3D vision system which eliminates the use of a physical device like a controller or a teach pendant to request robotic responses.

- GOLEM Project

The humanoid robot called GOLEM is a GeaorgiaTech project that is designed to be in perfect standing balance. The robot only has 2 wheels and is balanced to execute various tasks involving stability. Two Robotiq end effectors are used on this project to enhance the flexibility of the robot. By having two Grippers on two independent Schunk 7-axis robotic arms, the robot can achieve a very wide array of tasks. The lab had a list of specific tasks it was expecting to accomplish and this is the reason why they wanted to use a 3-Finger Adaptive Gripper so they could achieve all of them.

- DEOS Project: DLR German Aerospace Center

The project is testing a wide variety of satellite maintenance devices. By doing so, the final goal is to have an autonomous satellite maintenance device. It is the first time such an application has been developed. The 3-Finger Adaptive Gripper has been chosen to achieve different maintenance tasks. Thanks to its reliability and flexibility, the Gripper will be able to work on different kinds of satellites using a wide variety of tools with the ultimate goal of repairing the satellites.

The project is testing a wide variety of satellite maintenance devices. By doing so, the final goal is to have an autonomous satellite maintenance device. It is the first time such an application has been developed. The 3-Finger Adaptive Gripper has been chosen to achieve different maintenance tasks. Thanks to its reliability and flexibility, the Gripper will be able to work on different kinds of satellites using a wide variety of tools with the ultimate goal of repairing the satellites.

This is just a few of the applications that can be accomplished with our mechanical Grippers. If you want to learn more about the different research applications that are being done with our Grippers you can consult the e-book in the link below.

Leave a comment