Robotic End Effector Trends and Types – Webinar by RIA

Posted on Apr 29, 2014 8:00 AM. 4 min read time

On Thursday, March 13th the Robotic Industries Association (RIA) presented a webinar on robot end effectors such as parallel, vacuum and magnetic based designs. Laura Simpson from RIA introduced the presenter, Adil Shafi.

The webinar mainly started with a general description of mechanical, vacuum and magnetic end effectors, which is helpful for a first time user or person looking into robot end effectors for the first time.

Robotic End Effector Market Trends

An interesting point made by Mr. Shafi was his discussion on market trends in robotics. For those of you interested in where the robotics market is going or seems to be going, his point about the US Food and Drug Administration or FDA having new powers to shutdown non-complying food industry plant facilities, thereby encouraging the installation of robots to avoid contamination issues, highlights an interesting potential market.

He presented a graph which showed for 2013 the reduction of robot end effectors in the automotive and automotive component market of 33 percent, which is fairly substantial though it must be recognized that this is a mature market. Whereas the rise of robotic end effectors takes place in Food and Consumer goods at 67 percent and life sciences, pharma, biomedical at 73 percent. Again you can see the trend in emerging markets and the convergence of service and industrial robots.

Along this line you can check out, Samuel Bouchard's recent presentation at Shunk Expert Days in Germany for a presentation on market trends concerning the convergence of service and industrial robots. This trend is born out by the statistics for 2013 presented in this RIA webinar.

Robot Grippers, Vacuum Cups and Magnetic End Effectors

A description of robot gripper types follows, pointing out the differences between vacuum and magnetic models, with a general discussion of the factors relevant to choosing a particular type of vacuum end effector, like surface and material type, as well as new technologies for holding an item without continuously running your air compressor.

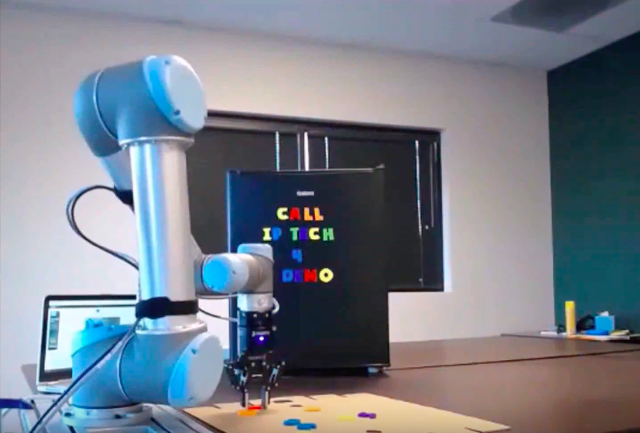

Pneumatic End Effector vs Servo Grippers

Then the increasing importance of flexibility in mechanical grippers was highlighted. With an important distinction between pneumatic and servo grippers explained, including the ability of servo grippers like Robotiq's 2 and 3 Finger Grippers to be able to precisely control the grasp on an object, whereas with pneumatic grippers the air is either on or off, which doesn't provide you with much control.

During the presentation on mechanical grippers the importance of cable management was discussed as an important aspect of gripper malleability. Assuring that the connection to the arm provides enough flexibility and rotational capability in the cables to avoid wear and tear is important for the maintenance life of the robot. Solution approaches such as two or three position grasp with parallel and 3 finger models were also presented.

Tool Changers vs Flexible Robot Grippers

Examples of a robot arm using a tool changer pointed out the advantages of this approach, which easily connects and disconnects the end effector, though having to connect a custom designed and produced end effector for each application doesn't seem as efficient or flexible as it could be if only one gripper was used. For example, with Robotiq end effectors you don't necessarily need to change your end effector as the same one is capable of handling many different applications. Increased cycle times and floor space as considerations in cell organization were also mentioned.

Tools to Choose the Right End Effectors for your Robotic Application

At the end of the webinar many videos of different types of end effectors were shown. Noting that it is important to correctly measure the power capabilities of the end effector to include both the item you want to lift and the end effector which will be doing the lifting. You can read a blog article by Guillaume Robert on how to choose the right end effector for your application, which discusses this point in detail.

Again the importance of the weight of the object and the robot gripper is important here, but also important to consider is the addition of the inertia added if the object is being moved, which is often the case or point of the whole application. So adding in a calculation for: object, plus end effector, plus movement inertia, shows you why this quickly becomes more complicated than it might appear at first glance and why a gripper with a high payload is crucial. Read this post on the difference between robotic end effector payload and grip force to learn more.

In the end as RIA states these webinars are a good educational tool for expanding on certain subjects like; end effectors or robotic welding. So, be sure to mark your calendars for the next Robotiq sponsored webinar concerning robotic welding on Sept 25th.

Leave a comment