Top 5 Important Robotic Trends According to Robotiq

Posted on Nov 13, 2013 11:46 AM. 4 min read time

In the last few years, major technological advancements have been developed and are responsible for changes in industrial robotics. These changes will transform the use of robots in manufacturing in many ways. Robotiq has done some research and found 5 important robotic trends that are most likely to change the industry.

#5: Reassignment of human workers

The new types of industrial robots are now able to handle various tasks that previously were only accessible to humans. The new systems allow the robots to do hazardous and monotonous tasks. We are not talking about replacement, but rather about reassignment of workers. The employees will take over more value-added tasks such as management. Reducing health hazards and increasing productivity can also results from this new trend.

#4: New robotic welding technologies

Talking about hazardous jobs, welding is the most used joining method in industries, but this process is not risk-free. Over the past years, robot welder has come on the market and helped companies to increase their product quality and productivity. Nowadays, skilled welders are becoming rare and companies need to replace them. In order to do so, using robotics in welding seems to be one solution, but programming these systems can be quite complicated and still needs in-depth programming knowledge.

Fortunately, new technologies on the market are about to change that by allowing any worker with a little training to set up a welding robot. Robotiq is part of this solution with Kinetiq Teaching. This systems is in fact a force sensor that will help program a robot. The operator just needs to follow some easy steps and direct the robot by hand to the desired location.

#3: Robotics for small and medium companies

Industrial robots are becoming more accessible to small and medium sized companies. This is due to the new technologies allowing small volume and high mix production. Moreover, the accessibility of industrial robots at less than $50,000 is opening the door to robotics for small companies. Fast and easy set up of the robots is also a reason why it is now more accessible to these companies.

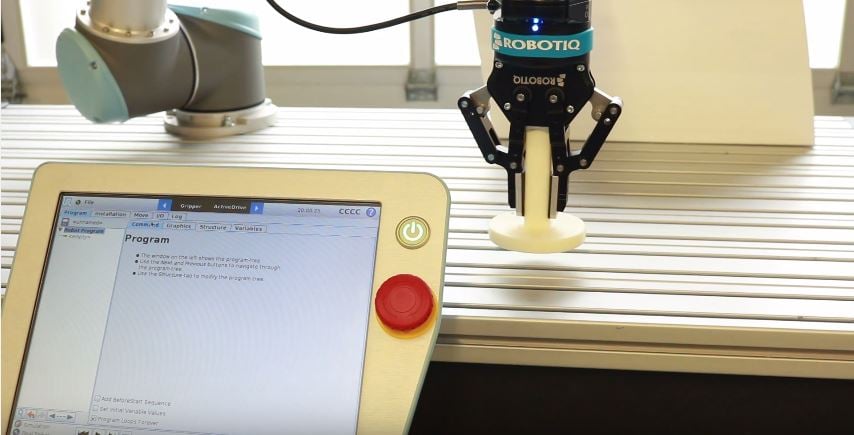

#2: Flexible Automation

The new challenge in manufacturing is about low volume and high mix production. Industrial robot manufacturers are working hard in order to design robotic systems that can handle various parts on an assembly line. Different processes are now used to create more flexible automation. Whether by using adaptive components or by using vision technologies, the market is looking for flexible solutions that will help them to get a good return on their investment.

Robotiq is providing flexible robotic end effectors for gripping application. Our Adaptive Gripper can mechanically adapt to any shape part. The 3-Finger Robot Gripper offers different gripping modes such as encompassing, pinch or scissor mode. The 2-Finger Adaptive Robot Gripper - 85 can adapt to parts up to 85 mm wide. For larger payloads and size, the 2-Finger Adaptive Robot Gripper - 200 can be your solution.

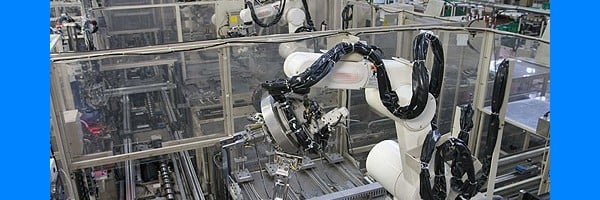

#1: Collaborative Robotics

According to Robotiq, the major trend that the robotic industry is experiencing involves collaborative robotics. These new kinds of collaborative robots are about to change the way robots are used in manufacturing. There will be no more barriers or safety cages needed with these robots. Their integrated safety systems allow them to work side-by-side with humans without any risks. They use force sensors or electrical current limitation systems to avoid any collision that could result in damage or injuries. There are already a lot of collaborative robots on the market within a varied price range, each one offering specific characteristics. In order to know more about them, you can read our ebook that introduces 9 different robots and includes a comparison chart of their characteristics.

Robotiq believes that these 5 important robotic trends will change how robotics are used in industries. Opening them to a whole different world of possibilities that will benefit both the companies and the employees.

Leave a comment