Project VALERI: Collaborative and Mobile Robotics on Shop Floor

Posted on Oct 08, 2013 11:54 AM. 3 min read time

Fraunhofer Institute for Factory Operation and Automation (IFF) is coordinating numerous projects to test new technologies in the industrial world. In this article, we would like to inform you about one of their projects named, VALERI.

VALERI stands for “Validation of Advanced, Collaborative Robotics for Industrial Applications”. In fact, this project is about testing collaborative robots in real industrial environments to evaluate their benefits. Since the beginning of this year, collaborative robots really are the new stars of industrial robotics. Being able to work side by side with humans, industrial robots would take over monotonous jobs, to let human workers do more value-added tasks. These new robots are full of promise, but it is now time to really test them. As always, research departments are in advance of the industrial world and even if the popularity of collaborative robots started this year, the VALERI project started in November, 2012.

VALERI stands for “Validation of Advanced, Collaborative Robotics for Industrial Applications”. In fact, this project is about testing collaborative robots in real industrial environments to evaluate their benefits. Since the beginning of this year, collaborative robots really are the new stars of industrial robotics. Being able to work side by side with humans, industrial robots would take over monotonous jobs, to let human workers do more value-added tasks. These new robots are full of promise, but it is now time to really test them. As always, research departments are in advance of the industrial world and even if the popularity of collaborative robots started this year, the VALERI project started in November, 2012.

The Institute, their industrial partners: Airbus Military, FAC, IDSPA, KUKA Laboratories, as well as their research partners: Profactor and PRODINTEC, all teamed up to design a real scenario where collaborative robots and mobile robotics will be evaluated. The evaluation is scheduled to last 3 years.

The project

In order to test mobile robotics, the group decided that the manufactured parts should be very large ones, so they chose the aerospace industry. In this kind of manufacturing, stationary robotic systems may not be the right solution economically. The main challenges encountered are the large individual parts, the price pressure due to the competition, small batch sizes and long-lasting quality products.

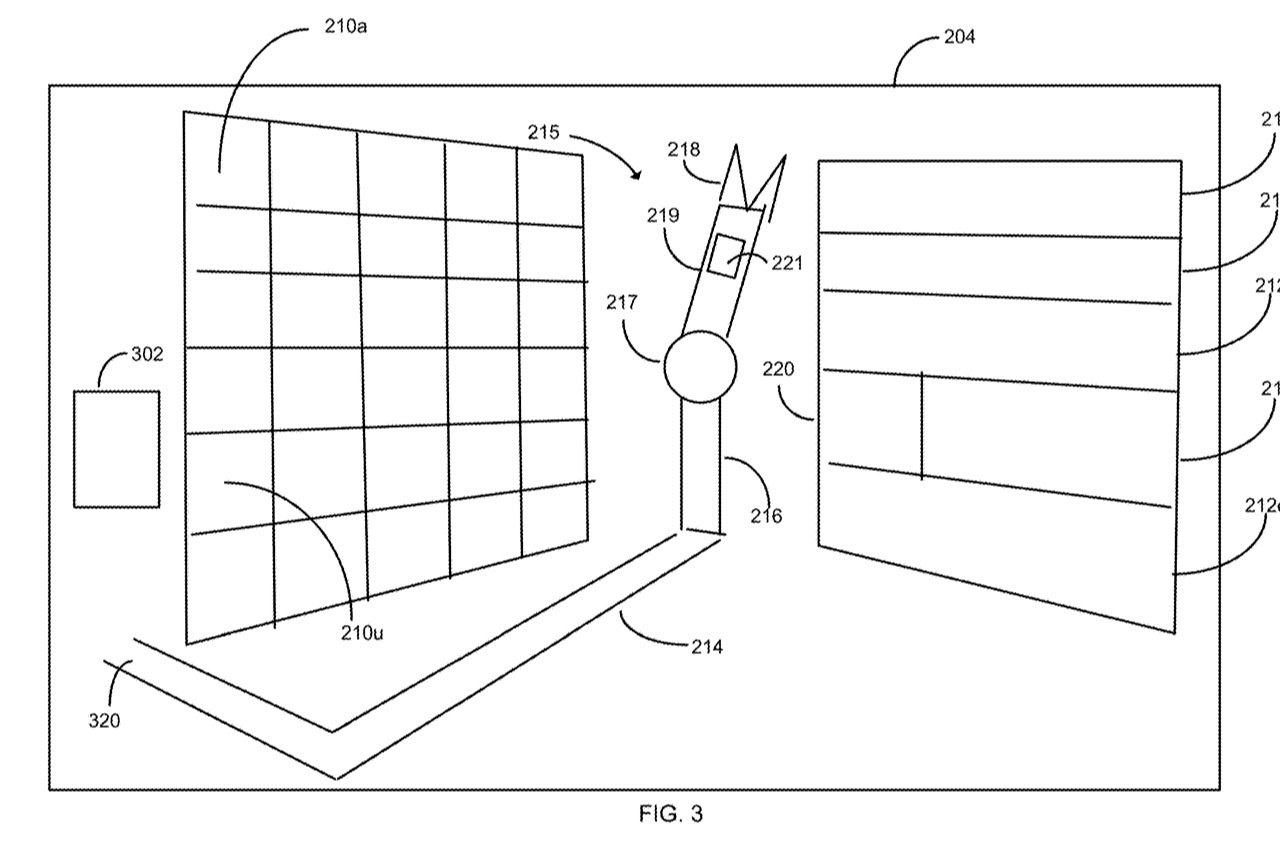

The group decided to install a KUKA LWR robot arm on a mobile platform to assure its mobility. The robot will have similar tasks to do in multiple stations. Moreover, this robot arm can be programmed very easily and fast using demonstration technology, which increases both speed and flexibility.

The robot will have two exemplary tasks to do:

- Inspection of large surfaces

- Applying sealant along grooves

In order to achieve these tasks, different elements will be considered.

- Multiple safety technologies will be integrated onto the research platform to assure safe human-machine collaboration.

- Vision systems will also be used to help with the navigation, part recognition, and visual part inspection.

- The team also wants to simplify the programming needed on the shop floor and is considering the use of haptic devices for control.

- They also want to enlarge the workspace of the robot and evaluate its efficiency.

Goals

With their different tests, Fraunhofer and its partners want to demonstrate that mobile manipulators can work on multiple production lines because of their flexibility. Since, human-robot collaboration is an important aspect of these tests, the robot will be able to move around freely without any fences. For the inspection tasks, the robot will provide information on autonomous path planning technology. Finally, with the vision system used, the team will have a proof-of-concept for using photometric inspection systems to push their research further in the area of sensing technologies.

In conclusion, VALERI will provide valuable information to develop and prove the application of collaborative robots and mobile robotics on the shop floor. It will for sure enhance robotics in manufacturing.

And all the results will be applicable not only in the aerospace industry, but also in many other manufacturing sectors.

We are looking forward to seeing their conclusions.

Leave a comment