The 2016 International Collaborative Robots Workshop is Here, What Should we Expect?

Posted on May 02, 2016 7:00 AM. 4 min read time

The RIA is hosting its International Collaborative Robots Workshop (ICRW) in Boston on May 3rd and 4th. Our CEO, Samuel Bouchard, will be presenting on how to get started with collaborative robots, along with his thoughts on the new technological advances and automation opportunities available for manufacturing SMEs. An event to look forward to!

IT'S ALL ABOUT SAFETY .png)

At last year's workshop, Samuel noted that safety was the main topic in every conversation (read his takeaways here). Everyone agreed that safety was an important piece of every application and that a risk assessment was essential, but what wasn't clear for manufacturers was the right way to do a risk assessment. This is especially true since back then the safety standards weren't as well defined.

With the advent of the recent ISO/TS 15066, we'll see if this tech spec has brought some clarifications to manufacturers regarding how to do a proper risk assessment or if it only brought more questions.

THE BIG 4 ARE READY TO ROCK THE COBOT MARKET

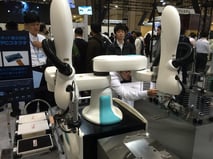

The four leading industrial robot manufacturers unveiled their new cobots last December at IREX in Japan.

- We saw Motoman/Yaskawa presenting the HC10 that will likely be released this year.

- Fanuc released a complete line of collaborative robots in addition to their CR-35iA (the CR-4iA, CR-7iA and CR-7iA/L).

- ABB presented Roberta dressed in white, alongside Yumi, (remember when ABB bought Gomtec?).

- Kawasaki showed the dual arm scara robot: duAro.

For more info, read our review of the new cobots we saw at IREX, from the big players to the new kids on the block.

According to Frank Tobe from The Robot Report, Fanuc, Yaskawa, ABB and Kawasaki have respectively 400k, 300k, 250k and 110k robots installed worldwide. Those are massive numbers compared to Universal Robots, the collaborative robot market leader, who has about 7,000 cobots installed in the field since 2009. With such big players entering the cobot market, can we expect cobots to become a commodity for manufacturers in the future?

Possibly, but first, we all need to focus on safety, flexibility, price, ease of programming, training and education of the market. I will go out on a limb and say that these will all be hot topics in the ICRW crowd.

Talking about market education, did you know that we have a free resource center? Have a look here.

THAT'S GREAT, BUT HOW DO WE GET STARTED WITH THOSE COBOTS?

This is the question that Samuel Bouchard will be discussing at ICRW in Boston next week, here's the agenda. More and more SMEs are counting on collaborative robots to help them foster new hires and retain a qualified workforce, increase their production rate and reduce production costs. But for most companies with limited resources, it can be difficult to decide where to begin with their first cobot project.

Hint: start small, get going today, and build on your success.

Here are the 5 most frequently asked questions we get regarding collaborative robots:

- What can collaborative robots do in the manufacturing process?

- How to identify automation potential in your factory?

- How to get your workforce onboard with automation and robots?

- How to assess which manufacturing cells should be automated?

- How to present your case to management?

We published an eBook covering these questions, you can download it here.

Will you attend ICRW next week? Let us know what you think will be the hot topics of discussion, we're always looking forward to having a chat about robotics and manufacturing!

Leave a comment