What Industry 4.0 Means for Manufacturing and Logistics

Posted on Aug 22, 2016 7:00 AM. 4 min read time

Many people in the manufacturing and logistics industries are waiting for that one new technology that will completely transform the way their business works. Well folks, we are here to inform you that the technology is already all around you, and just waiting to be taken to the next level in order to join the industry 4.0 revolution. This will be a time in which all aspects of your production and logistics are intelligently linked together, allowing for big data mining that will optimize, well, everything. If you don’t believe that the revolution is upon us, it’s time to start doing your research to see what potential you already have right under your nose, and how you can capitalize on it.

What Is Industry 4.0?

Also known as the Internet of Things, Industry 4.0 is a term that was coined a few years ago by German engineers to indicate the fourth industrial revolution – the interconnectedness of all aspects of manufacturing and distribution. The fourth revolution follows the first three, which were mechanization, electrification, and computerization. Now with the connected world, or the Internet of Things as it is most commonly known in North America, we look forward to intelligent business systems that leverage big data for better solutions in manufacturing and logistics, and even things like product design and marketing.

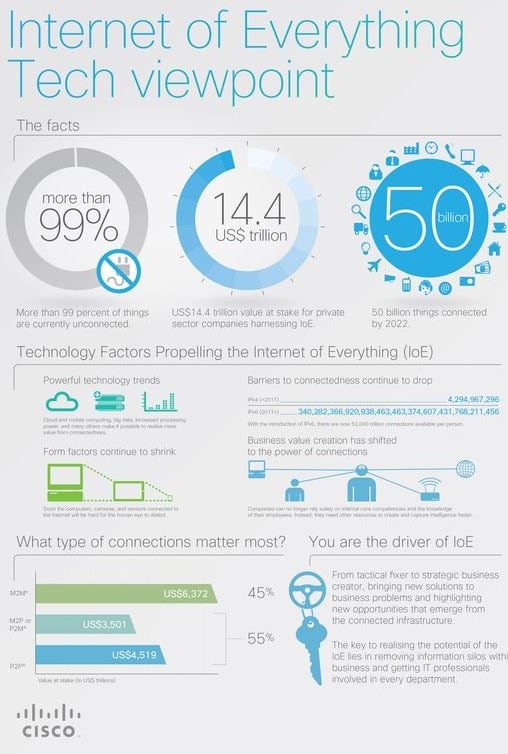

Cisco predicts that the Internet of Things has $14.4 trillion USD at stake as an industry, and will lead to over 50 billion connected things by the year 2020. This is in contrast to our world today in which it is assumed that 99% of devices remain unconnected. The technologies that are central to this paradigm shift aren’t necessarily the devices and machines themselves, but rather the services around them, like cloud and mobile computing, processing power and big data analytics. They predict 45% of all connections in the world will consist of machine-to-machine communication, while the other 55% will be divided between machine-to-person and vice versa, as well as person-to-person. Companies that are already leveraging Industry 4.0 opportunities are seeing entirely new business models come out of their investment, as well as staggering increases in productivity.

Connecting Your Entire Production Cycle

- Data Collection and Analytics

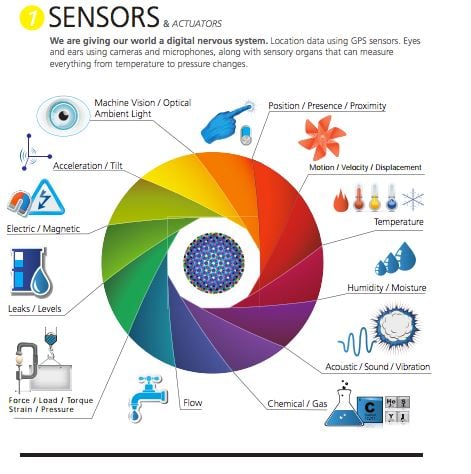

Big data is characterized by the three Vs: volume, velocity and variety. These are data sets that are so dynamic and complex that they require processing much more powerful than the traditional methods. Arising in such varied formats, big data is really of no use unless it has the proper analytics tools to make it the incredibly powerful tool it can be for business, especially in the manufacturing industry. It is also central to industry 4.0, which aims to leverage new forms of data to optimize business processes across the board. If you are already using automation in any step of your manufacturing or logistics process, you are poised to fit your machines with a number of different sensors that will inform you of the smallest risks and changes in production. Machines are now capable of vision through sensors like the Camera Plug + Play Vision System by Robotiq; knowing where they are geographically through GPS sensors; hearing through microphones; and even keeping track of sensory data like temperature and pressure change through what are called organ sensors. These are just a sampling of the new data you can collect and analyze with smart devices that will allow you to better monitor your manufacturing so you can make smarter decisions.

If you are already using automation in any step of your manufacturing or logistics process, you are poised to fit your machines with a number of different sensors that will inform you of the smallest risks and changes in production. Machines are now capable of vision through sensors like the Camera Plug + Play Vision System by Robotiq; knowing where they are geographically through GPS sensors; hearing through microphones; and even keeping track of sensory data like temperature and pressure change through what are called organ sensors. These are just a sampling of the new data you can collect and analyze with smart devices that will allow you to better monitor your manufacturing so you can make smarter decisions. - Smarter Machines Mean Smarter Business

With proper analytics tools, probably in the form of Software as a Service applications, Industry 4.0 will undoubtedly increase your productivity by allowing you to optimize weak points in your process. Sensors have the intelligence to keep you informed of things like machine wear or malfunction. This means that operators now have the foresight to know when parts will need to be replaced and can ensure that they have those ordered before the break occurs. If a machine breaks down, an operator will have data to analyze in order to give them a better idea of what exactly the problem is so they can fix it once and for all.

With machine-to-machine communication downtime will undoubtedly be decreased as they can now communicate to each other and operators that they are finished a certain task and ready for another. This will allow operators to further optimize the timing of manufacturing and minimize lag times in production while coordinate better with logistics at the same time. Your machines can also inform you if there are problems with product quality during the manufacturing process. If a product is not meeting the standards of production, ideally you can fix it before it's too late. This means that you will waste fewer resources in the way of physical products as well as labor and even waste production. - Continual Optimization

The truly empowering aspect of the Internet of Things is that improving your production is no longer based on your annual audit of the line, but can be a continual and cyclical process that is renewed every day with automated reports. With the ability to be informed of risks and weakness in your manufacturing and logistics through automated systems, your operators are now freed up to focus on debugging those snags in real time.

The benefits of adopting the Industry 4.0 business strategy are endless wells supplied with evergreen data to analyze continually. If you are looking to vamp up your manufacturing and logistics, the time has come to turn to the Internet of Things for the answers. Its potential is already being realized and it will be the next thing to give you a competitive edge in your industry.

If you are already using automation in any step of your manufacturing or logistics process, you are poised to fit your machines with a number of different sensors that will inform you of the smallest risks and changes in production. Machines are now capable of vision through sensors like the

If you are already using automation in any step of your manufacturing or logistics process, you are poised to fit your machines with a number of different sensors that will inform you of the smallest risks and changes in production. Machines are now capable of vision through sensors like the

Leave a comment