Playing with Legos just got a Boost to the Next Level !

Posted on Jan 25, 2016 7:00 AM. 3 min read time

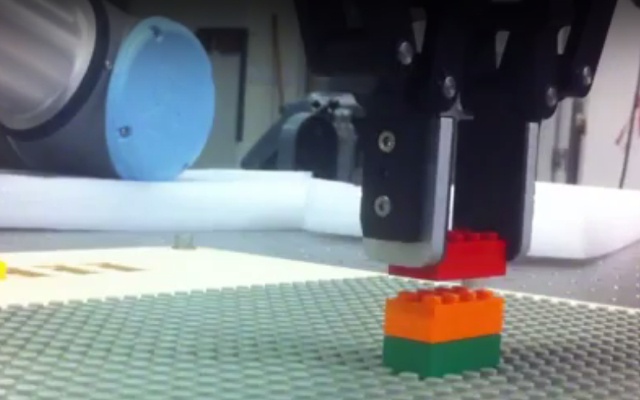

Yesss, playing with Legos just got funner, well maybe not for your five year old, but for the AFOLs out there. In fact, the game that consists of creating different structures, shapes, cars and planes with blocs is now making its way into the future. We are now actually able to assemble Legos with a robotic arm. Such a thing was not possible a couple years ago for various reasons. Let's see what makes it possible now?

But first, here are a couple of videos that show how things are done.

ArtiMinds Christmas tree

Some of the videos have a Christmas theme. Since we are just out of the holidays, it makes sense, right?

MIT students are playing with Lego during undergrad??

In one of the MIT labs, you can spot students playing with Legos... well, they are not actually playing, they are learning and who said learning had to be boring.

Robotiq Playing with Legos at Olympus Games

Here is a short video from one of our sales people who went to visit one of our distributors (Olympus Controls) and set up a robot arm to reconstruct a Christmas tree made of Legos.

So how it is done?

All videos have common points. They all use:

- force feedback to locate and fix the Lego block at the right spot.

- Adaptive Grippers to grasp different types of blocks with the same Gripper.

- collaborative robots.

Using Force Feedback

The force feedback is achieved with a Force Torque Sensor such as the FT 150 to able to sense what the robot is feeling. In fact, in this particular case, you need to know if one part is well aligned with the next part. To determine this, you cannot use vision, you need to feel it. The exact same way a human would recognize the clipping of the 2 blocks, the robot will recognize the exact same thing. Without this device, the robot would simply go to a requested position and wouldn't know if the block was inserted correctly or not.

Adaptive Grippers

Such technology enables the user to grasp all the different Lego shapes and sizes with a single Gripper and with a single programming path. The fact that the Gripper can adapt to the width of the part, makes the operation a lot easier. Another nice feature of the Gripper is that it is force limited, in this case, you can put a small force setting and not crush the blocks.

Collaborative Robots

It is not obligatory to use a collaborative robot like the UR5 for this type of application, but you should note that they are a lot safer than a regular industrial robot. This means that you can play Lego with or alongside the robot. :)

The other much appreciated aspect of these robots is the fact that they are easy to teach. In fact, using the teach by demonstration technique, you can easily show some path points to the robot and create a basic routine with the robot. It is a lot easier to program than a regular robot, so you have more time to build your Millennium Falcon!

If you need more information on how to achieve a project with a Force Torque Sensor, I highly recommend to take a look at the eBook on Force Torque Sensor – An Introduction.

Leave a comment