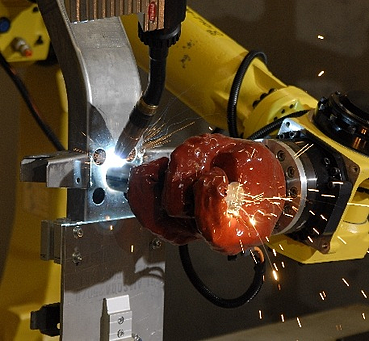

Integrating a Robotic Welding Process - Part 3 - Selecting Your Integrator

Posted on Jun 03, 2014 8:00 AM. 4 min read time

This is the third and last article featuring several tricks and tips on integrating a robotic welding cell into your workshop. If you haven’t seen the previous articles (Part 1 - Pre-Diagnosis for Robotic Welding Implementation and Part 2 - The Feasibility Study) you should definitely take a look at them before checking out this post. Just a quick reminder that the advice in these articles comes from our customers and contacts in the welding industry, therefore they should be taken seriously. Even if some points sound overwhelming, you should definitely go through all of these points to have a proper robotic integration.

Part 3. Selecting Your Integrator

Government funding

A certain amount of support is provided for new technologies by different governmental entities; welding robot integration could be on the list for your region. Since funding regulations change between every country and province or state, contact your local government representative to see if they can help you out with your proposed technological integration.

Integrator list

Compile a list of all the integrators in your area and see what their skill levels are like for the following points:

-

Experience in welding and vision: This should be the main point when choosing an integrator. This company needs to have a broad range of experience and with different types of integration so that they can solve a problem quickly.

- Implantation capacity: Do they have time for your integration? Most integrators are quite busy so make sure that you schedule your integration wisely.

- Costs and deadline: A good integrator should be able to respect the budget and deadlines you have set at the beginning of the project.

- Proximity: There is probably a good integrator on another continent, but you need to consider the fact that proximity is synonymous with economy.

- Training: Some integrators offer training and technical support, which will help you out when debugging your robotic cell.

- After-market: Having an integrator that can come and see if your robot is working well and give you some supplementary tips is always a good thing.

Set your goals

As robotic welding is a huge market, you need to establish your planned results regarding: quality, cycle time and integration time. As you set these goals, stay realistic and try to respect them as much as possible.

Choose your integrator

Now that you have listed all of the integrators, you are able to make a wise choice. You can decide which one most suits your company and which one can do the best job. Ask to see different integration projects that they have created and ask to be in contact with customers that have been satisfied with their work. Make sure that you give the integrator a very clear project plan that includes technical data from your shop, for your robot operations including cycle time(s). It might even be worth your time to propose your plan to different integrators so that you can have a better idea of the value of your project. In other words, request quotes from 2 or 3 integrators. Some integrator offers maintenance services, this could be a good point to direct your choice.

Evaluation

Once you have received all the quotes, evaluate which one is the best for your robotic application. Establishing a spreadsheet will help you to clearly see the different options.

Communication

I believe (and will always believe) that communication is the key in robotic integration. Present your plans to your shop’s employees and introduce them to industrial automation. Some people see robotization as a bad thing. Make them understand your point of view, as it will reduce the resistance facing the integration of the robotic cell. Also, make sure that you wisely determine the operator responsible for the robotic cell. Once these employees have been determined, involve them in the different meetings and decisions regarding the project.

With the mentioned tips in these articles, you now have all the tools necessary to have an easy integration. As I said, take these steps seriously without skipping any of them. This advice can save you a lot of time in your integration.

Leave a comment