Cobots vs. Covid Initiative: Eliminate Delays

Posted on Apr 20, 2020 10:00 AM. 4 min read time

- This article is the last in a 7-part series supporting our Cobots vs. Covid initiative:

If you are a manufacturer ramping up production of mission-critical goods, Robotiq wants to help you deploy a cobot application in two weeks. - Watch our 23-min video explaining the program.

- Ready to take action? Contact us now.

- Today’s article: How to leverage the current situation to eliminate delays

Key to Success #6: Eliminate Delays

In the previous five key-to-success articles, we talked about what you have to do to deploy cobots in two weeks:

- Start simple. Identify the right application.

- Keep it simple. Stick to the must-haves, avoiding nice-to-haves and feature creep. Get the cell in production ASAP and improve from there.

- Standardize. Use standard plug-and-play components as building blocks to accelerate your project.

- Start with the manual task. Capture all relevant info from the current manual task before jumping into the cobot cell design.

- De-risk the design early. Stress-test your design before you commit to it, to avoid unpleasant surprises in the Integrate phase.

The key to success #6 is in fact the result of all the previous ones: Eliminating delays and other types of waste will get you to a productive robot cell ASAP. This is the essence of lean robotics, which becomes even more crucial when you need to deploy the cell in two weeks.

The current context of remote work and travel bans has eliminated some waste, but it also created potential new sources of waste that we must pay close attention to.

- Waste that has been eliminated

- Travel time and expenses → Let’s take advantage of it!

- Waste that could increase if we aren’t careful

- Communication delays → Since we can’t have face-to-face meetings, holding all discussions digitally could slow down the process with delays and miscommunication.

- Extended shipping delays → Carriers and supply chains are facing greater demand with fewer resources, so delays are more likely to happen.

- Rework, trial and error → Since we are exploring new ways of collaborating and working faster, we could end up needing more rework later.

- Communication delays → Since we can’t have face-to-face meetings, holding all discussions digitally could slow down the process with delays and miscommunication.

- Waste that could potentially be reduced

- Waiting for budget approval → These unprecedented times require fast decision-making.

- Waste of human potential → Human adaptability is of even greater value in uncertain times. This is a great opportunity to leave repetitive tasks to the robots and free people to provide much-needed agility.

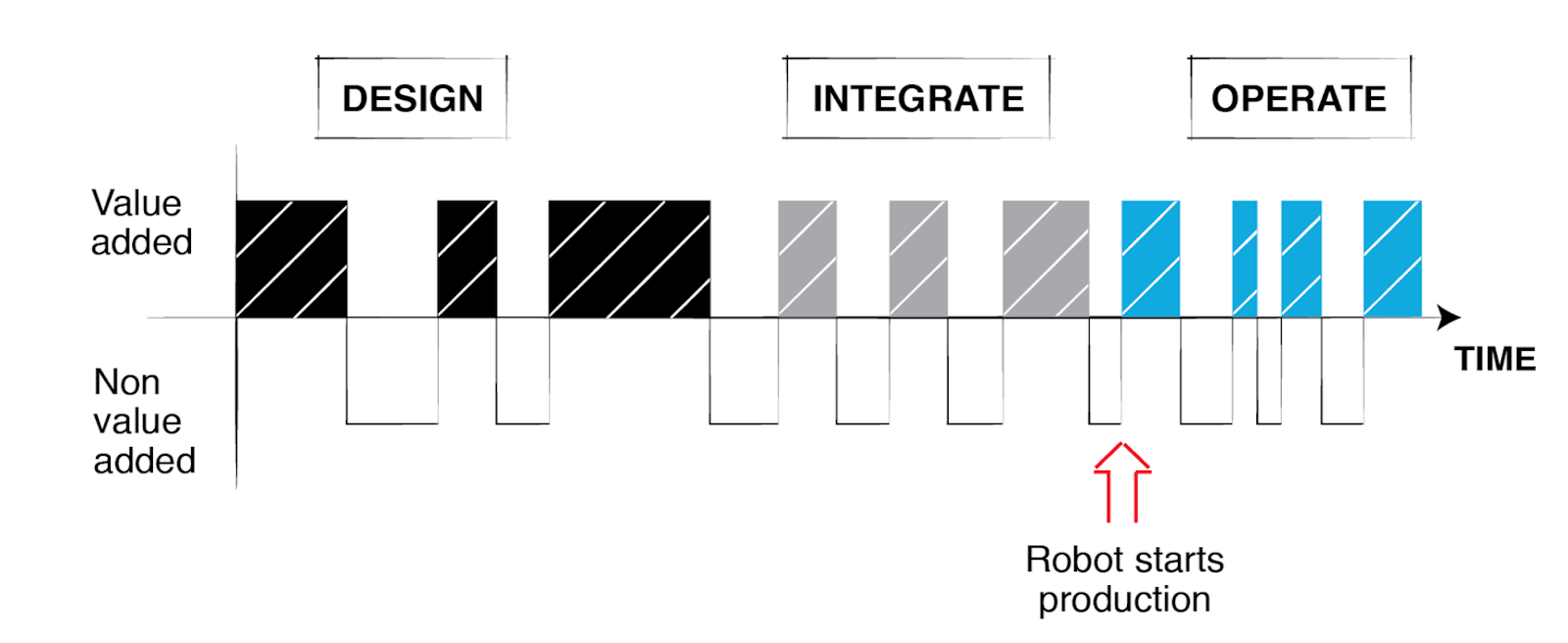

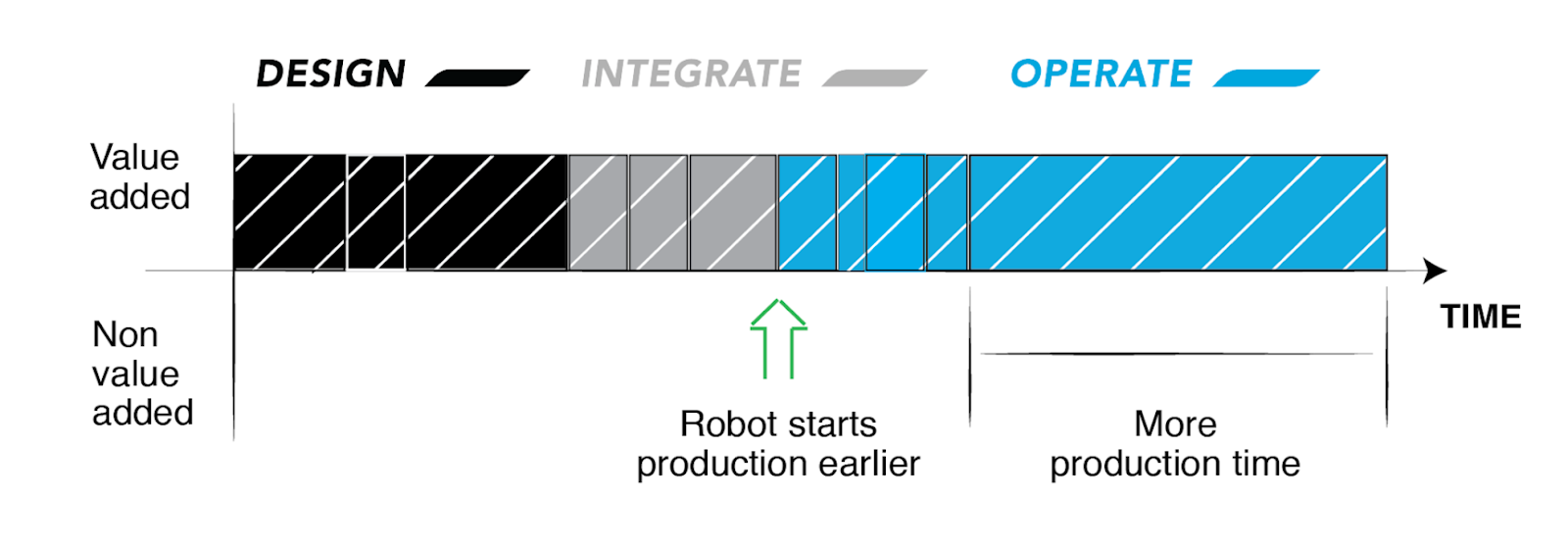

The two figures above show the impact of eliminating waste in the cell deployment process. If we want the Design and Integrate phases to happen in under two weeks, we must eliminate delays.

How We Will Work as a Team and Eliminate Delays

Let’s see how the accelerated but systematic lean robotics process will help us eliminate delays to achieve our goal of deploying a cobot cell within two weeks.

Eliminating communication delays

We will leverage proven remote-collaboration tools like video and robot remote access. This will let us see the application to automate, the challenges you’re facing, and the robot system directly.

Eliminating extended shipping delays

The key here is to leverage the standard plug-and-play components available off the shelf. The most widely used ones are in stock at Robotiq or with your local Expert Partner (we have 50 of these highly capable partners across the globe).

While you’re waiting for parts to arrive at your factory, we won’t be doing nothing. We will use this time to train you and the team—providing a tailored training plan combining specific e-learning modules and remote lessons— so you can hit the ground running when your shipments arrive.

Eliminating rework and trial-and-error

The key to avoiding rework is a well-done design phase that respects the principles of starting simple, keeping it simple, standardizing on plug-and-play components, starting with the manual task, and de-risking the design early.

By combining your expertise in your process and our expertise in robotics, we will make it work. Let’s do it!

Want to take action?

Leave a comment