Cobots vs. Covid Initiative: De-risk the Design Early

Posted on Apr 17, 2020 10:00 AM. 3 min read time

- This article is the sixth in a 7-part series supporting our Cobots vs. Covid initiative:

If you are a manufacturer ramping up production of mission-critical goods, Robotiq wants to help you deploy a cobot application in two weeks. - Watch our 23-min video explaining the program.

- Ready to take action? Contact us now.

- Today’s article: Why de-risk early is important and will save you time in the long run.

Key to Success #5: De-Risk Early

In the previous four key-to-success articles, we talked about what you have to do to deploy cobots in two weeks:

- Start simple. Identify the right application.

- Keep it simple. Stick to the must-haves, avoiding nice-to-haves and feature creep. Get the cell in production ASAP and improve from there.

- Standardize. Use standard plug-and-play components as building blocks to accelerate your project.

- Start with the manual task. Capture all relevant info from the current manual task before jumping into the cobot cell design.

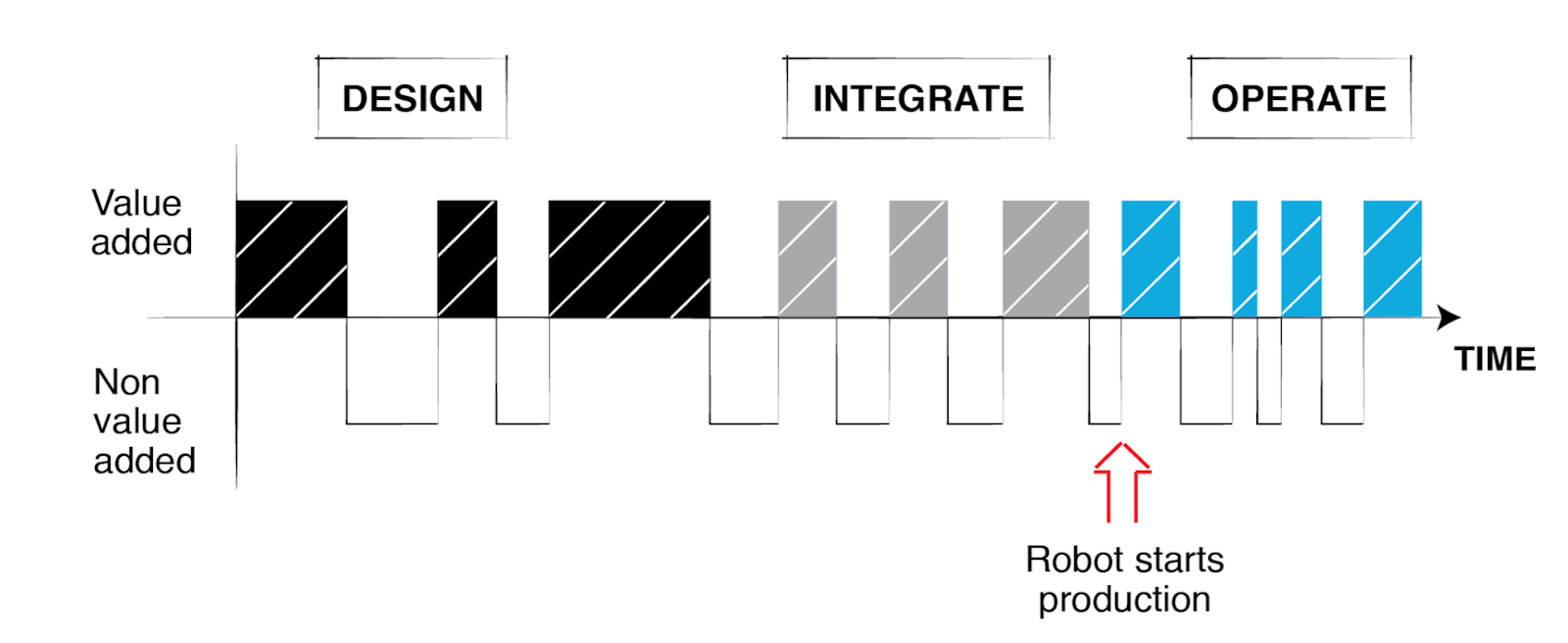

In the most recent article, we explained why it’s crucial to understand the problem thoroughly before defining the solution. This article builds on that last step, to cover why and how you need to stress-test your design early enough to avoid unpleasant surprises in the integration phase. The argument is the same: a small, systematic investment early in the project can save costly and stressful rework during the crucial integration phase, when it has a greater impact on the rest of the line.

De-risking should be done once you have an initial concept for the cobot cell, but before you finalize it. The idea is to test all the critical elements of the design—anything that can have a major impact on the viability of the solution.

How to Identify Critical Elements

Consider each element of your design (functionalities, integration, supply, training, reliability, etc.) and answer the following two questions:

- How confident are you that this element will work?

- If it does not work, what will happen?

For instance, if it doesn’t work, will your whole cell fail, or it will just make things a little harder on the programming side?

How to Test Critical Elements

We’ll need to test all the elements you have identified as low-confidence, high-impact, or both. With our help, you'll use two methods.

- Simulation. We’ll be able to test your robot’s reach and any cycle-time risks with simulation very efficiently.

- Experiment. Some aspects of the design can only be tested experimentally. This typically includes:

- Tooling questions (Will the gripper be able to pick the part? Will the finishing tool provide the right finish?)

- Sensing questions (Will the vision system work? How about force sensing?)

- Processing questions (Will we reach the target cycle time? How about the desired quality?)

- Integration questions (Will these devices work together properly?)

How We Will Work as a Team to De-risk the Cell Design

This is another area where using standard building blocks makes a huge difference in efficiency, because:

- Using digital manufacturing techniques, Robotiq coaches can run experiments.

- Your Robotiq Integration Coach will do simulations on the design to clear the reach, cycle time, and layout questions.

- If real experiments must be done, your Robotiq Integration Coach will run a test using rapid 3D printing—which saves you from the delays involved in exchanging parts.

- Using standard plug-and-play components eliminates integration risks.

- Standardization lets us leverage experience from thousands of previous projects to do a realistic evaluation of the risk, and in most cases, bring the confidence to a level where trial and error are not necessary.

- Robotiq and our global network of local Expert Partners are all equipped with cobots and the Robotiq toolbox. So if an experiment must be done, the setup for it will be readily available close to your factory, avoiding costly delays.

Want to take action?

Upcoming article: Key #6 - Eliminate Delays

Leave a comment