Cobots vs. Covid Initiative: Start With the Manual Task

Posted on Apr 15, 2020 3:19 PM. 3 min read time

- This article is the fifth in a 7-part series supporting our Cobots vs. Covid initiative:

If you are a manufacturer ramping up production of mission-critical goods, Robotiq wants to help you deploy a cobot application in two weeks. - Watch our 23-min video explaining the program.

- Ready to take action? Contact us now.

- Today’s article: How to leverage standard components to start production in two weeks.

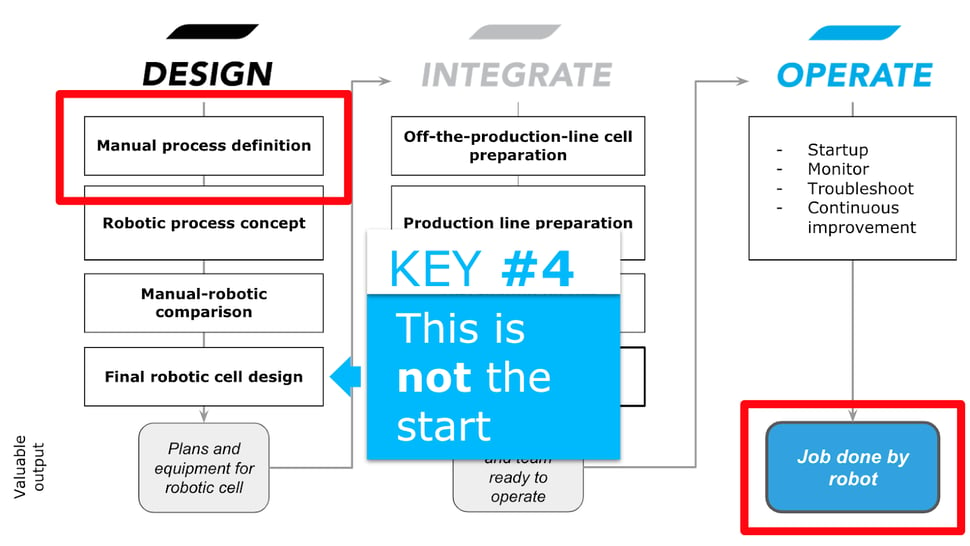

Key to Success #4: Start With the Manual Task

In the previous three articles, we presented two fundamental keys to success if you want to deploy cobots in two weeks:

- Start simple. Identify the right application.

- Keep it simple. Stick to the must-haves, avoiding nice-to-haves and feature creep. Get the cell in production ASAP and improve from there.

- Standardize. Use standard plug-and-play components as building blocks to accelerate your project.

In this article, we'll present the tried-and-true advice we have given to thousands of manufacturers: start with the manual task.

This is a situation to which the famous Abraham Lincoln quote applies:

“Give me six hours to chop down a tree and I will spend the first four sharpening the axe.”

In other words, you must fully prepare for the problem before jumping in with a solution. Too often, we are tempted to skip mapping the manual task to jump right into designing a cell and choosing technology. But we have a saying at Robotiq: Think slow, act fast. Slowing down and thinking systematically at the beginning will actually help you achieve the end goal faster, of having a productive cobot cell that helps you ramp up capacity.

The key is to avoid surprises and delays. One particularly frustrating kind of delay is rework, which means doing something for a second (or third, or fourth... !) time because it wasn’t done properly in the first place. Jumping to solution design too fast can cause unpleasant surprises later in the deployment. Not only will rework be annoying but in a tightly scheduled project, it can increase pressure to a painful level. The last thing you want to do is realize that important aspects of the cell are not working just when you’re stopping the production line to implement the robot.

How We Will Work as a Team to Map the Manual Task

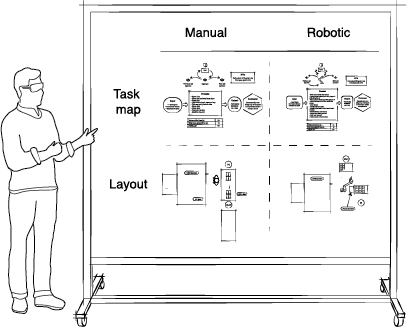

The two main tools we will use with you to capture all the manual tasks information are videos and the Lean Robotics manual task mapping steps.

- There’s no better way to capture manual task information than with video. We will ask you to film the manual task and its environment and upload it to Blueprints, or simply hop on a video call with us.

With this information and by asking other questions, we will complete the manual task mapping steps as defined in Lean Robotics. This systematic approach will ensure we capture all the info we need for the upcoming cell design phase on the first pass. This approach will cover the process, part infeed, outfeed, durations, communications with other machines, and more. By combining your understanding of your process and our experience with cobot deployment, we’ll be in good shape for the rest of the project.

Want to take action?

Upcoming article: Key #5 - De-risk early

Leave a comment