Increasing Productivity in Manufacturing: Which Variables Should We Look at?

Let’s first ask ourselves, which variables have an impact on productivity?

ISO/TS 15066 Insights: Adjust to Scale

Companies thinking about implementing collaborative robot solutions need to decide the degree to which they build up in-house...

ISO/TS 15066 Insights: Risk Assessment Goldilocks

The two most common mistakes made during robotics-related risk assessments are oversimplifying and over-complicating the...

ISO/TS 15066 Insights: Take an Application-Centered Approach

One of the most common misunderstandings around power and force limited collaborative robot systems is that some people assume...

ISO/TS 15066 Insights: Do Your Background Research

If you have never carried out a risk assessment before, begin with some basic background research, says Lasse Kieffer, Global...

ISO/TS 15066 for the Real World: Manufacturing

Honda has used collaborative robots for safety rated monitored stop applications. These applications enable robots to be loaded...

ISO/TS 15066 Insights: Talk with Stakeholders

The first step in every risk assessment is getting the stakeholders together and talking about safety, says Dave Smith, a...

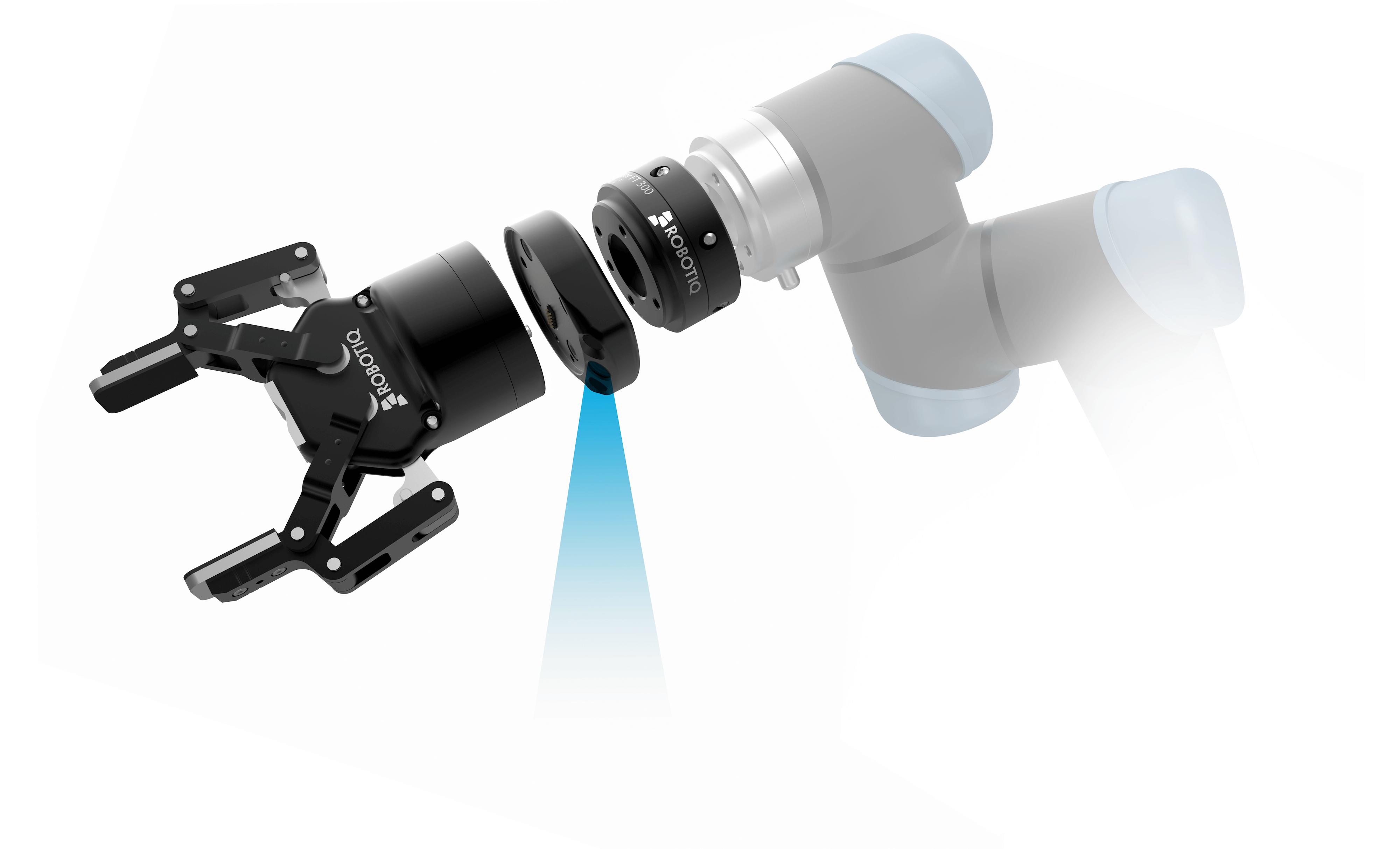

New Robotiq Vision System Breaks Down Integration Barriers

We are proud to launch Camera, our new vision-guided pick and place solution for Universal Robots that shortens setup time to...

Increasing CNC Productivity: More Machines, Outsourcing, or Robots?

In a business, if we do everything right and the market is on our side, we eventually get to the beautiful problem of too much...

Leave a comment