ISO/TS 15066 Insights: Talk with Stakeholders

The first step in every risk assessment is getting the stakeholders together and talking about safety, says Dave Smith, a robotics safety expert at Honda Canada Manufacturing. It turns out that this first step is also one of the “biggest benefits” of performing a risk assessment.

“A lot of times people think risk assessment is a bunch of different, difficult steps you have to go through,” says Smith. “But really, it's just a bunch of people getting together to ask 'What do we want to do? What are the hazards going to be with that? What controls do we need to put in place to do that?' The risk assessment, the formal side of it, is about documenting those conversations and having a method to go through it.”

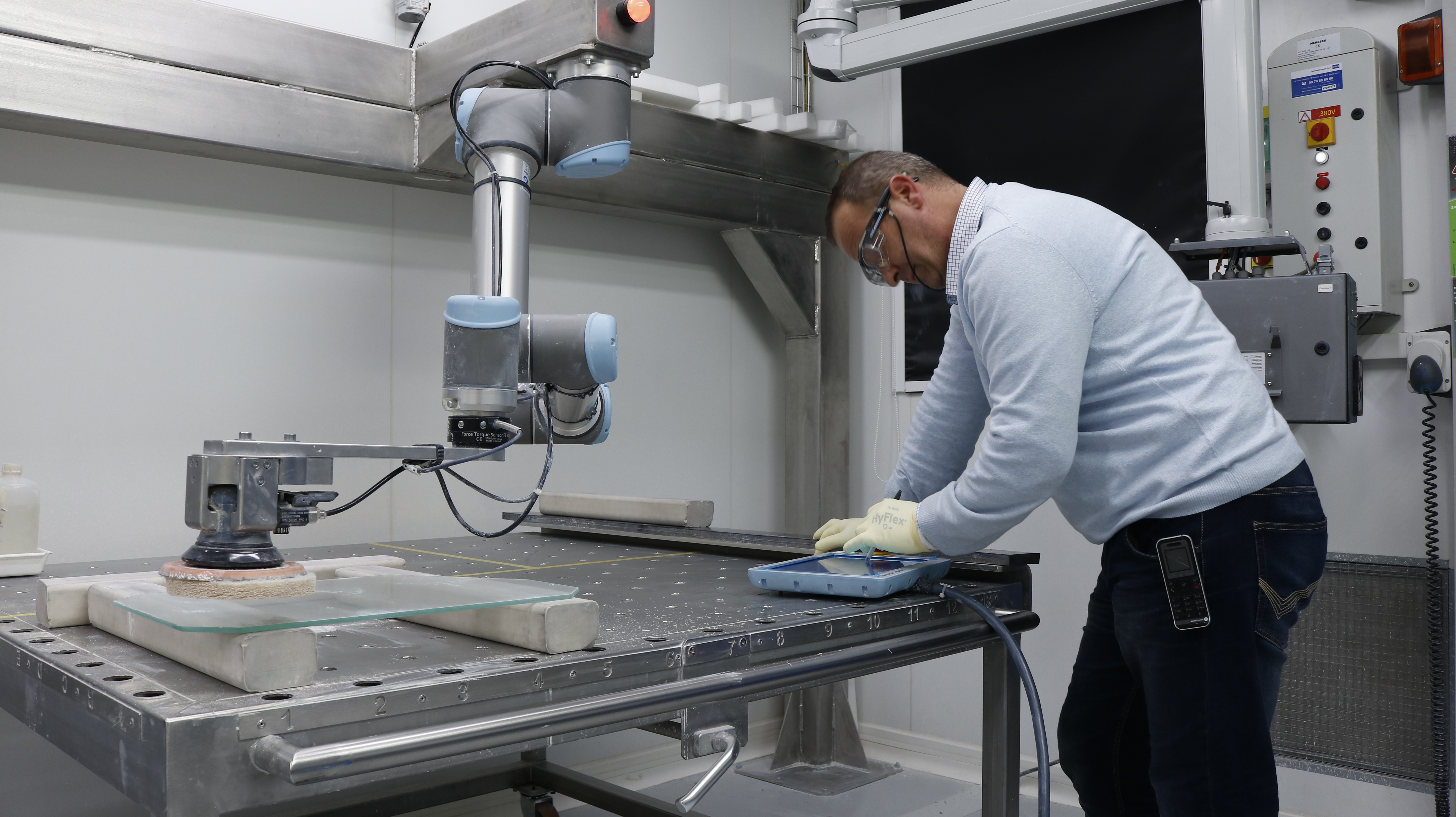

Long before a robot system is purchased, the automation engineer, the workers, and (particularly in the case of small companies) the owner need to talk with each other to understand what some of the risks might be, advises Smith.

“It's all about getting those stakeholders together and talking about it at the right time --before you buy the robot and before you try to implement the application. The risk assessment has to be done at the design stage or at the concept stage to be effective.”

Pilz's robot safety expert Elena Dominguez, agrees.

“Seek support. Talk to third-party groups and integrators. Visit users who are using collaborative robot systems even if they're in a different industry. See what they did. Ask 'What did you learn?' and 'What mistakes did you make?',” says Dominguez, who recommends the RIA's annual safety conference as an excellent place “to go learn some basics and to network.”

ISO/TS 15066 Explained

We interviewed members of the ISO Committee who wrote ISO/TS 15066 to get their input and provide more context to the document. This eBook will make these new technical specifications easy to understand. It covers the reason why it was written, how it affects the factories today, and why it's important. Even better, it explains the content of the technical specifications in the context of real-world scenarios you can relate to.

We interviewed members of the ISO Committee who wrote ISO/TS 15066 to get their input and provide more context to the document. This eBook will make these new technical specifications easy to understand. It covers the reason why it was written, how it affects the factories today, and why it's important. Even better, it explains the content of the technical specifications in the context of real-world scenarios you can relate to.

Leave a comment