5 Super-Dangerous Jobs That Robots Can Do Safely

Some jobs are just too dangerous for human workers. Robots are increasingly used to improve the safety of workers performing these tough and dangerous tasks. Here are 5 super-dangerous jobs that robots can do safely.

Credit: The Fabricator

Here on the Robotiq blog, we've often written about robots tackling the "3 D's of Industry." That means they're perfect for jobs that are "dull, dirty, and dangerous."

Most of us can relate to the "dull" part of this. After all, we all have parts of our jobs that are boring and we'd prefer to give them to a robot. But, what about jobs that are "dangerous?"

How dangerous are we talking here?

There are some jobs that are so dangerous, a robot is absolutely the best way to achieve them. Before long, these jobs might only be done by robots. In the future, we'll look back on when people used to do these jobs and think "How could a human ever do that!?"

Here are 5 super-dangerous jobs that robots can do safely. Giving these jobs to a robot will immediately improve the safety of the human workers in your business.

1. Lifting very heavy (and slightly heavy) objects

Robots are often used to lift very heavy objects. Want your robot to lift a whole car? No problem, there are robots that can do that easily. These lifting tasks wouldn't just be dangerous for humans, they would be impossible (unless you've hired the Incredible Hulk to do palletizing in your warehouse).

However, the most dangerous heavy lifting tasks actually involve objects which humans can lift… but shouldn't lift. Repeated lifting of objects between about 15-50kg can be extremely dangerous for workers. A strong worker will be able to lift a 30kg weight. However, if they lift this weight many times a day, they are likely to overexert themselves, use increasingly bad posture, and there is a chance of permanent injury.

Some health and safety guidelines recommend that people should not lift over 25kg, but there is no hard-and-fast limit. Even lighter weights than this can be dangerous.

Robots are perfect for repetitively lifting heavy loads. There are even a couple of collaborative robots that can handle very heavy lifting, such as the FANUC CR-35iA (payload: 35kg) and the Comau Aura (payload: 170kg).

2. Stirring 2000°C molten metal

There are some jobs that are still performed by humans but probably shouldn't be. One such job is "furnace tapping," which can be extremely unsafe when the furnace is big. This job involves stirring molten metal to remove a waste by-product called "slag."

Furnace tapping requires workers to approach the molten metal (which can be at temperatures of 2000°C) and agitate it with a long oxygen lance. The working environment can be extremely hot and filled with noxious fumes. As the worker "taps" the furnace, they are drenched in a cascade of burning sparks. Here's a short video of someone performing furnace tapping in a very large furnace.

A recent editorial by the Robotics Industries Association highlighted how this repetitive and highly demanding job can now be achieved by robots. Robot arms are wrapped in a heat-protective covering which allows them to withstand the high temperature environment. They are equipped with custom-built oxygen lances which they use to remove the slag.

3. Collecting and packaging radioactive waste

The handling of radioactive materials is a job that has involved robots since before the 1980s. It's easy to see why: it's impossible for humans to handle any radioactive materials without some risk to their health.

With small doses of radioactivity — e.g. in medical applications — the worker's safety is managed by limiting the total radiation that workers receive per year. However, with very high levels of radiation — e.g. when handling radioactive waste from nuclear power plants — the only option is robotics.

The most common robots used in the nuclear industry are telerobots, which are remotely controlled by human workers. The environment is often too unpredictable and the tasks too varied for autonomous robotics. The MARS robot, for example, is a remotely operated arm which uses a high powered jet of liquid to clean up the radioactive waste at a facility in Hanford, Washington, USA.

Robotic manipulators have also been proposed as a way to package radioactive waste, in an operation similar to packaging in a manufacturing environment.

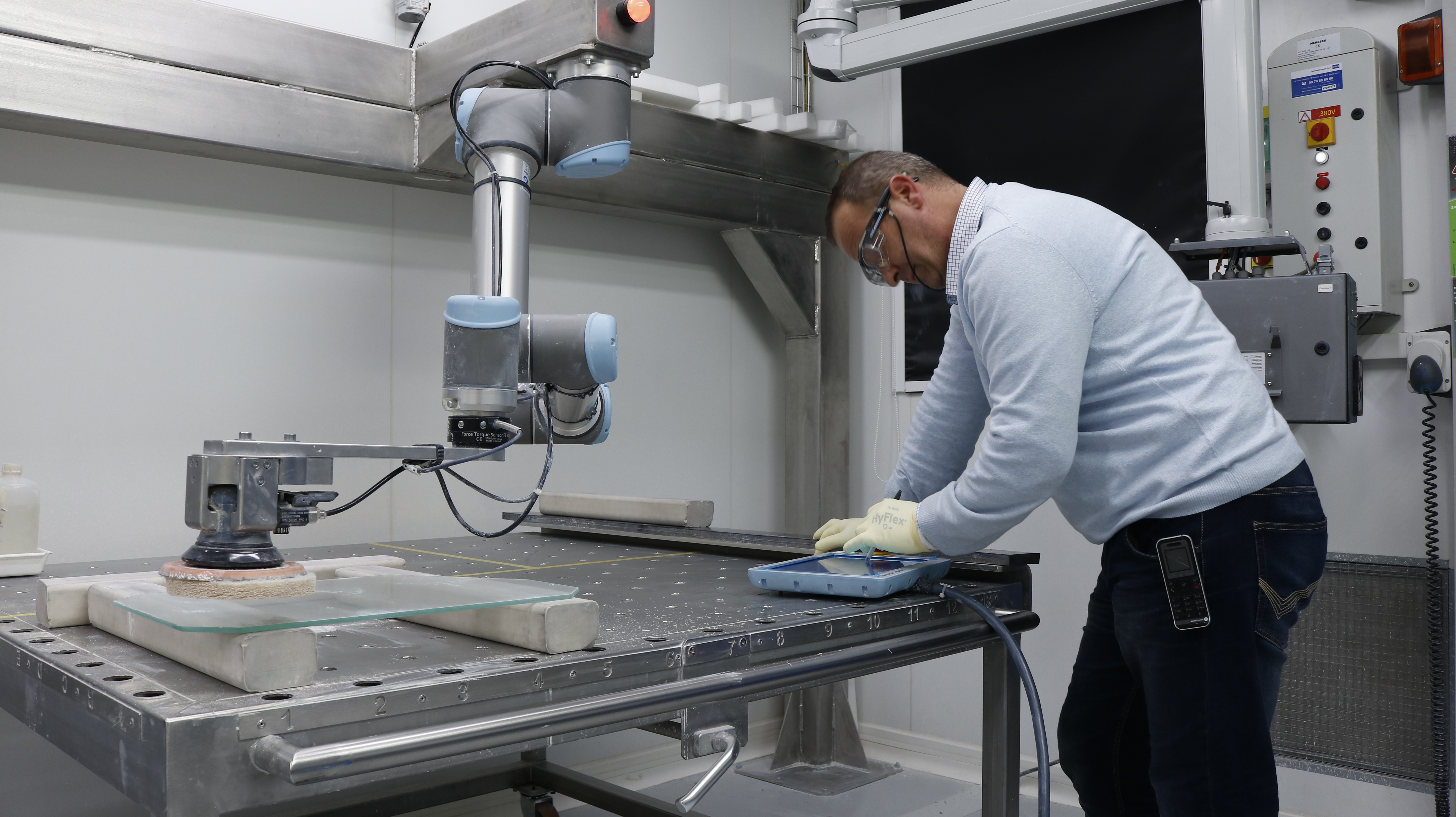

4. Working in contaminated, dusty environments

In some jobs, the cause of danger is the unsafe working environment. For example, jobs like industrial battery manufacture can produce toxic dust which would be highly hazardous if inhaled by human workers. Some drug manufacturing processes can also produce fumes and dust which are filled with dangerous chemicals.

Dust is a danger to humans. Workers in very dusty environments are prone to respiratory problems and have an increased chance of contracting lung cancer. This is true even when the dust contains no contaminants. However, the risk is increased even further when the dust contains chemicals, radiation, or harmful substances.

Robots can improve worker safety in contaminated, dusty environments. However, you need to make sure the robot itself is able to operate within dusty environments. You can do this by using a robot with an appropriate Ingress Protection (IP) Rating.

5. Repeating the same motion again and again

Robots are perfect for performing repetitive motions. It's what they are made for!

For us humans, repeating the same motion again and again is very, very boring. But, it can also be dangerous. There is a real risk of conditions like repetitive strain injury (RSI) and other musculoskeletal disorders. If the safety of the task is not improved, these disorders can turn into long-term, or even permanent, health problems.

There is also a business case for using robots for repetitive motions. Musculoskeletal disorders account for around 35% of work days lost to injury, so they can have a huge financial cost to businesses.

Thankfully, robots are a great way to remove this danger. They excel at repetitive tasks and don't suffer from musculoskeletal disorders — though they do need a little bit of maintenance every so often.

When a task looks too dangerous for a human worker, a robot can be the perfect solution to improve safety.

Which tasks in your business could be safer when done by a robot? Tell us in the comments below or join the discussion on LinkedIn, Twitter, Facebook or the DoF professional robotics community.

Leave a comment