IP Terminology and Ratings Demystified - Robotics

Posted on Aug 13, 2014 in Robotics

2 min read time

In the world of robotics, the abbreviation “IP” is often use and can easily be a source of confusion. From Industrial Protocol to Intellectual Property, it is important to distinguish the different meanings of the term “IP”.

IP: Industrial Protocol

Industrial Protocol is a programming language use for communicating with different robotic devices. You will find more information in this article: What Are The Communication Protocols Used In Industrial Robotics?

IP: Internet Protocol

This protocol is the main communication protocol for data transmissions across network boundaries. It enables internetworking and is the basis for the internet as we know it. More information can be found here: Internet Protocol.

IP: Intellectual Property

This “IP” is a legal concept that protects the development of something like an idea or an object and gives exclusive rights to its creator. It is often mentioned when talking about inventions or creations. For more information, follow this link: Intellectual Property.

IP: Ingress Protection

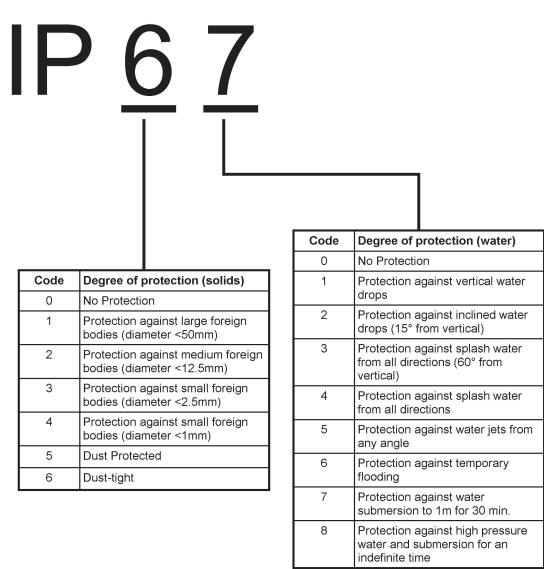

Now, this “IP” is the main concern of this article since it is related to mechanical conceptions such as robots. Ingress Protection or International Protection is a classification for the degree of protection afforded to a devices against intrusion of objects, dust or water. It is often use for mechanical casings or electrical enclosures. An example of this rating would be: IP 67.

Now, this “IP” is the main concern of this article since it is related to mechanical conceptions such as robots. Ingress Protection or International Protection is a classification for the degree of protection afforded to a devices against intrusion of objects, dust or water. It is often use for mechanical casings or electrical enclosures. An example of this rating would be: IP 67.

The first number stands for solid particle protection and the second one stands for ingress water protection.

A lot of robot and robotic grippers datasheets contain this information. These classifications are obtained by doing specific tests to insure that the device respects the specifications. It is very useful to determine whether or not the robot can withstand a particular work environment or do certain tasks such as welding, painting or underwater tasks without risking any damage. If the information cannot be easily found, do not hesitate to ask your robot supplier.

Leave a comment