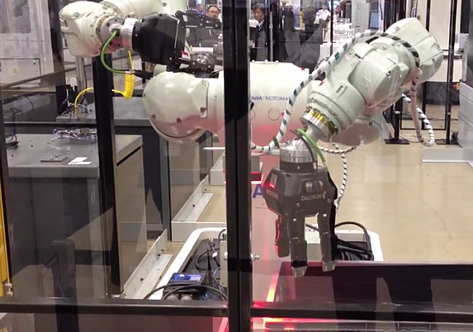

Robobusiness 2014: What is Advanced Manufacturing with Robots?

Posted on Oct 23, 2014 9:34 AM. 3 min read time

Recently, during Robobusiness, a Workshop on Advanced Manufacturing was held. As a sponsor of the event, we've put together a little video with some sequences coming from our customers to ask the question: "What is advanced manufacturing?" Is it experts pushing he boundaries of robotics? Or is it making robots accessible for everyone? In fact, the workshop answered mostly the latter question. Many discussions seemed like a flashback from the recent RIA Collaborative Robot Workshop. Here are a few notes and afterthoughts.

Make Robots Simple to Use... and to Choose

Once again, we were reminded of why 90% of manufacturing companies still aren't buying robots right now. They have determined that:

- Robots are too costly

- Robots are too complicated

Manufacturers want to make stuff, they don't want to program robots. They just want to use them. It's like with computers. They want to use them, they don't want to have to program them. To have truly flexible robots, the end effector is still a limiting factor for many applications.

One interesting aspect of the discussion was around the customer decision process. Not only is it important to make the robot simple to use, it's important for the customer if we can help him make a decision quickly. And this is not always obvious, to match the needs of a process with the capabilities of a robot. In many cases, we still need to go through trials and actual mock-ups, making the decision more complex and the cost of the sales higher. This is a real turnoff for many manufacturers.

Robot Skills that Manufacturers Need

We had a presentation from the coordinator of the European project, Factory in a day. The project aims at developing 'learnable skills' that a robot could quickly use to match the needs of a manufacturer at a given work station. The initiative looks at making robots easier to deploy, but also explores new business models. For instance, Ranstad, the world's second-largest human resource service provider, is involved in the project. To make robots easier to deploy, could it happen through different channels, leasing robots with specific skills for a period of time for instance? This is a very intriguing question.

Along the same lines, NIST is currently working with the robotics industry to develop methods to quantify capabilities needed on a job. The goal would be in the end to avoid gathering dust on some robots sitting in the corner of a factory somewhere, by making sure that a robot really has the capabilities needed to do a specific job. Benchmarking robot components (robot, perception, grasping, safety, interoperability, ease of adoption, etc.) and understanding the capabilities of the system once they're assembled is a very difficult problem considering the variety of tasks done in factories. In the mean time, the industry is moving forward without having the answers. But NIST's work could definitely provide some good methodology to help improve robot placement and components.

Factory-in-a... Day?

Dr. Wisse, coordinator of the project, scaled down expectations created by the catchy project title. He also told the anecdote that when they were preparing the grant proposal aiming at reducing installation costs and increasing reusability, Baxter came to market. This is another example that the robotics industry is gaining momentum and catching up with robotic research.

His presentation included the opportunity to watch a video on CellularSkin which might become a commercial product in the near future.

ROS, Yes... But

The question of whether or not ROS would be a key piece in advanced manufacturing with robots was asked. The answer was not overly enthusiastic. Everyone agrees that it brings interesting capabilities, but it has to be used as middleware behind the scenes. Right now, it's still too much of a developer tool to be front and center. It can be leveraged though to provide more capabilities to robots, making it, if we are to deploy robots on a large scale, more cost effective and easier to use.

Leave a comment