Why Industrial Manufacturing Tends to Automate Machine Tending

Posted on Sep 28, 2012 10:17 AM. 3 min read time

Walking the 2012 IMTS, confirmed my feelings that the automation of machine tending applications was becoming more and more a priority for manufacturers – read also Flexible Automation of Machine Tending Operations and our White Paper on machine tending automation. A lot of robot manufacturers and system integrators were presenting solutions including one of ours with Yaskawa Motoman.

Walking the 2012 IMTS, confirmed my feelings that the automation of machine tending applications was becoming more and more a priority for manufacturers – read also Flexible Automation of Machine Tending Operations and our White Paper on machine tending automation. A lot of robot manufacturers and system integrators were presenting solutions including one of ours with Yaskawa Motoman.

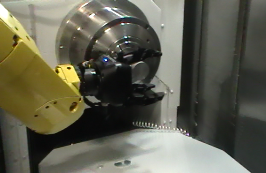

Motoman was indeed presenting the LoadWorld. You might be tempted to tell me: “There is nothing new there.” But this time the LoadWorld was featuring our 2-Finger Adaptive Robot Gripper! Equipped with two 2-Finger Adaptive Robot Grippers, the Motoman robot was handling a wide range of part sizes and geometries picked from different drawers and then either, placed in a chuck or different designated spots - see the application in the following video.

Looking at industrial manufacturing, we can easily understand why companies are shifting to automated machine tending operations.

Why Automate Machine Tending Operations?

First, the human resource issue. Good machinists are hard to find (and to retain!). Even if industry works hard to change the perception of manufacturing, what people have seen in the news the past few years makes a bigger impact.

Second, in this context, once manufacturers have skilled workers they want to put them to work on what gives added value to their products. And at the same time, giving them challenging tasks is often a good way to retain skilled workers.

Third, the product itself. Quality Control is always an issue in an industry and an economy where there is no room for waste (think of all the lean programs that companies are adopting for example). And if it is hard to get and retain skilled workers that means: 1) high staff turnover, 2) lack of product consistency, 3) waste, 4) increased production costs, and the vicious cycle goes on!

Is There An Issue With Automating Machine Tending Operations?

The answer would be yes… and no.

Yes, because machine tending applications often have to deal with a high-mix of parts. For larger companies having to handle similar parts or a high volume of different parts; this issue is only a technical issue that can be solve by designing custom robot tooling. However for smaller businesses dealing with high-mix, low-volume parts the issue is not only on the technical side, but also on the financial side. Indeed, the low-volume of different parts to be machined are often not profitable if we must design custom robotic tooling. In these cases flexible solutions are required.

No, because now flexible solutions such as our Robotic Grippers are designed for industrial applications. With the arrival of flexible robot grippers it is possible to handle a wide variety of part shapes and sizes with no compromise on precision – Read our white paper about it. The financial aspects can then be easily solved, leaving you to work on the technical aspects. To be able to use a single robot gripper to handle many different parts represents a huge advantage.

Final Word

Now that industry has flexible robotic tooling that can work with precision to support improvements in production processes and consistency in product quality; it is easy to understand why machine tending operations tend to be automated.

Leave a comment