The RUC Technical Challenge Is On!

Posted on Sep 06, 2018 3:37 PM. 6 min read time

Arguments, bonus points and a challenging production target. It can only mean one thing… the technical challenge is underway!

It's Day 2 of the Robotiq User Conference and the most exiting part of the whole event is underway: The Challenges!

The technical challenge and sales challenges are where the attendees really learn how to Start Production Faster. Theory is fine, but it's only when we put the concepts into practice that we really learn the power of the Lean Robotics methodology and the new cobot technologies.

The Technical Challenge: A 24 Hour Marathon Begins…

It's 10am this morning. All attendees are gathered in a crowd.

Behind a yellow tape which screams "ATTENTION" in big black letters there is… a huge black door.

What is behind it?

Everyone waits with bated breath. The door starts to slowly raise up.

As the door raises higher, people shuffle around, trying to get a better look. Some take out their mobile phones to snap photos and record videos.

As the light streams through from the hall behind, all is revealed. A staggering matrix of shiny collaborative robots, ready and waiting for the most exciting part of the Robotiq User Conference…

The Technical Challenge!

(cue dramatic music)

This is where our 10 teams will be staying over the next 24 long hours.

The technical challenge is truly a marathon. If it's anything like last year, we'll see people working into the early hours, unexpected problems arising when everything seemed to be working fine, and engineers staying awake on only coffee and determination.

It's Lean Robotics in action!

Over 24 hours (which started at 10am today and ends at 9am tomorrow morning) teams in the technical challenge will go through all three stages of the Lean Robotics methodology:

Design

They must design their cobot systems to achieve the requirements of the task. First, they must plot the manual process, then convert it to an automated process, then draw their plan for the robot cell.

This is a vital phase of the process. It's also a tricky balancing act. If the team rushes their design, they may find that it does not perform as expected when they get to the next phase. However, if they spend too long optimizing their design, it will lose them time for operation.

Integrate

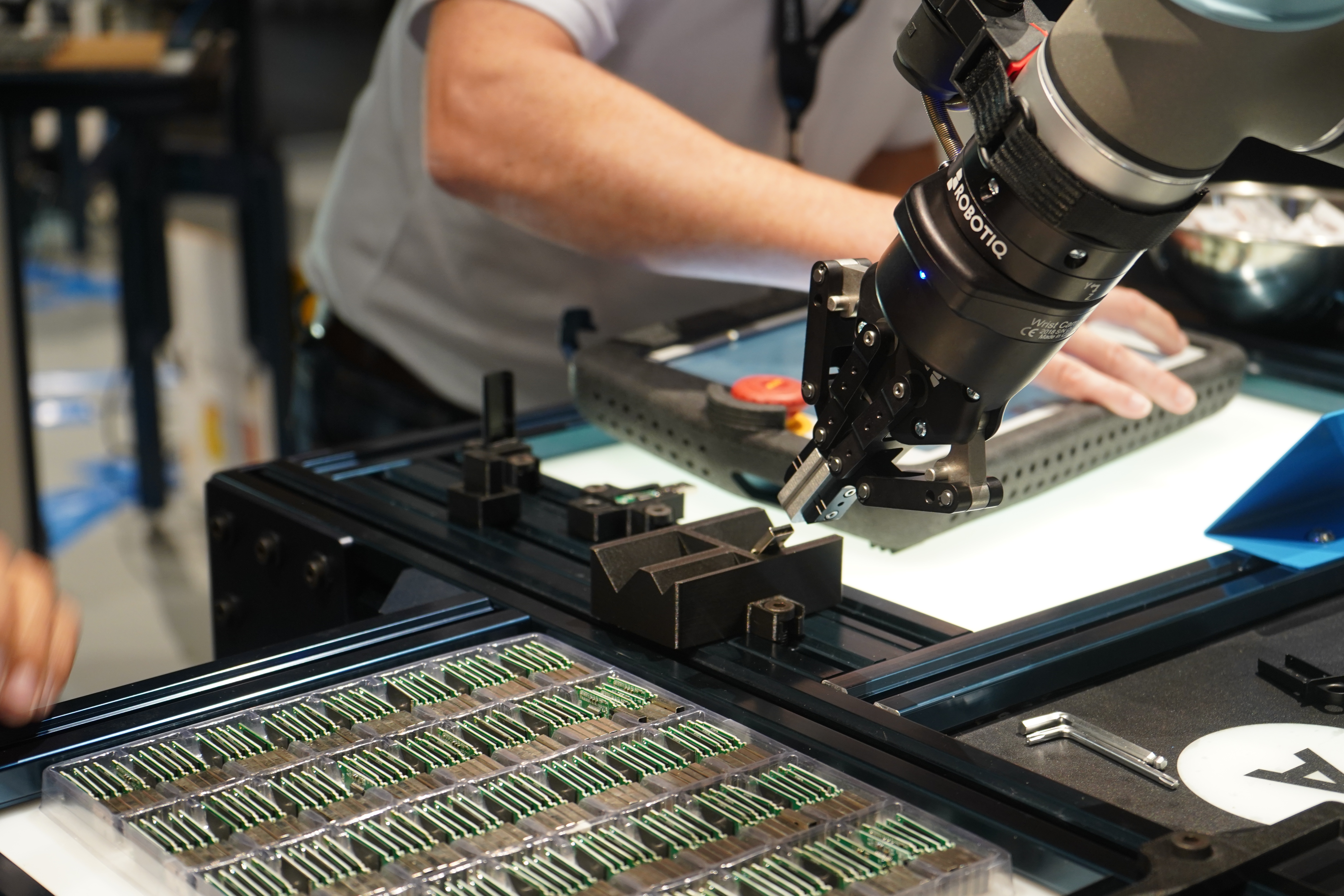

Possibly the most challenging task is the integrate phase. Here, the teams must setup and program the robots to complete the task. They'll have access to many of the Robotiq modules which Jean-Philippe introduced in his keynote yesterday.

Robotiq's Etienne Samson thinks that the difficulty of the challenge is the same as last year. However, the technology is much easier to use now, which should help during this phase.

Operate

The all important operate phase is where the production happens. As Samuel explained in his keynote yesterday "production" is the most important part of the process. After all, if we're not producing anything, what's the point?

One of the goals of the challenge is to produce as many 300 units as quickly as possible. Using the concept of Kaizen (continuous improvement) the teams can continue to improve their robot programming. But, there's always that trade-off: all downtime for reprogramming means time that the robots are not producing. However, they will have to optimize if they want to win the second goal of best cycle time.

Which will be the best strategy for our 10 teams?

Should they get to the Operate phase as soon as possible and aim for quicker production?

Or, should they take time to design an optimal system, potentially at the expense of production time.

What are they making?

The goal of the challenge is to reach a production target. To be specific, the teams have to produce 300 kits for a company called PromoStuff Inc. At the moment, there are piles of unassembled components. Soon, there will be piles of completed kits.

Each kit contains four items which have to be assembled and then arranged in a gift box.

- A screwdriver

- A pen

- A USB key

- An allen key

After doing a factory visit this morning, two representatives from each of team brought the project information to the rest of the team. Then they began work on the design phase.

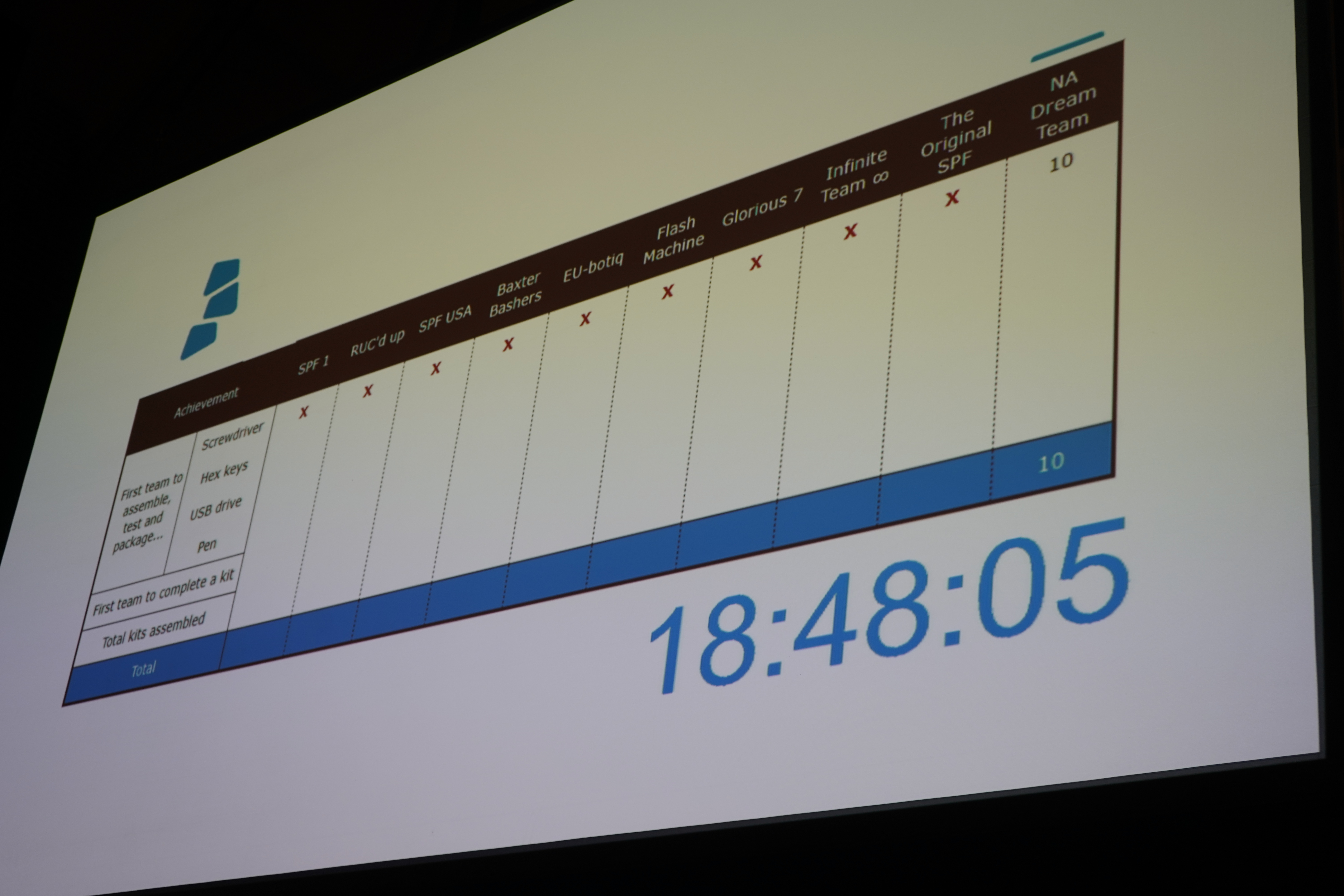

How do they win?

There are two goals for the challenge:

1. Reach the production target of 300 units.

2. Achieve the best cycle time.

The first team to reach the production target will win the first of these goals, but even after that has been achieved there is still an opportunity for teams to succeed by optimizing their cycle time.

The details of the task

If you're thinking that the task of packaging these items sounds easy, think again! Each item has a differing level of difficulty:

- The screwdriver — This is probably the simplest task. It involves taking the foam from the conveyor, putting it onto the robot surface, putting the screwdriver into the foam, and then putting it all back on the conveyor.

- The pen — This involves assembling a pen for use with the teach pendant, which is quite challenging.

- The USB Key — This is the most complex part of the task as it involves electronic assembly. The robot then has to feed the USB key into a testing machine, which uploads a file to it to ensure that it is working.

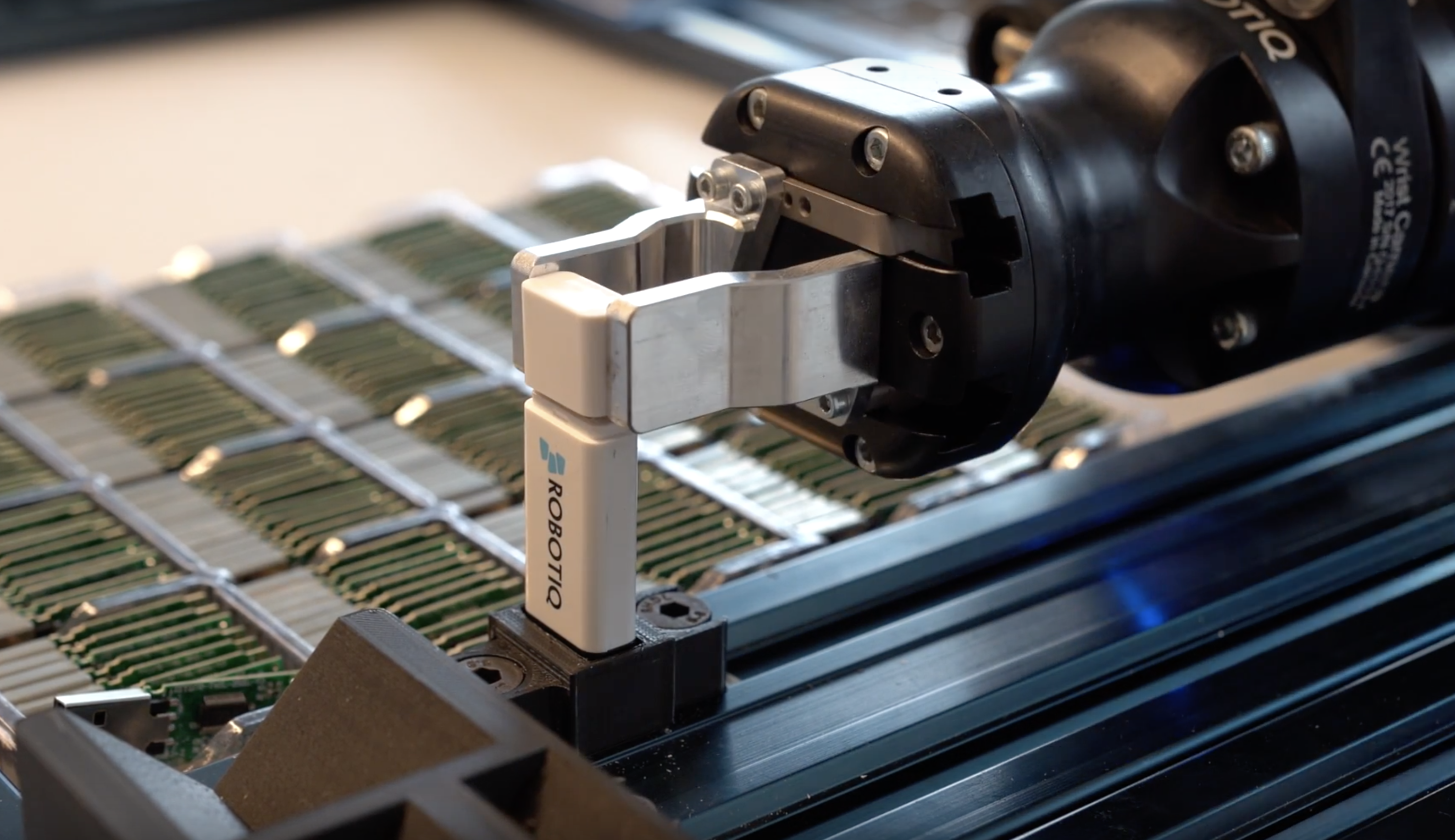

- Allen key — This is a challenging bin picking application. The allen keys are all arranged in bins and the teams must use the Wrist Camera to sort out them and arrange them into the kits.

How are the teams doing now? Arguing and scoring points!

It took maybe an hour or two to really get things going. The teams received their instructions and got to work on their designs.

They have now all completed the design of their cells and are well into the integrate phase.

The fastest team did their design in about 45 minutes. But, perhaps they rushed it a little bit because after a while they were kind of stuck. Most teams took an hour and a half to do their designs.

Some arguments over conveyor layout

The design phase is a little more complex that it was last year, which has caused a few arguments among the teams. Every part of the cells, both the robots and conveyors, are mobile so the teams can move them around however they want.

Almost every team has gone with a different conveyor belt layout. Some of the options teams have chosen are:

- Arrange each conveyor one after another in a line

- Arrange in a triangular shape

- In a U shape

- In an L shape

- In a T shape

Which is best? It's hard to tell right now! We'll probably know by this evening which is the most efficient layout.

Team 10 wins a bonus point

The first team to win a bonus point was Team 10, the guys from the Continental delegation from Mexico. They did a whole quarter of the task and earned some bonus points. They started with the screwdriver which was the simplest to program. Now, they're working on packaging the other items in the kit.

The first team to win a bonus point was Team 10, the guys from the Continental delegation from Mexico. They did a whole quarter of the task and earned some bonus points. They started with the screwdriver which was the simplest to program. Now, they're working on packaging the other items in the kit.

But, there are still more bonus points to be won! The first team to complete each of the four kit items will win a point.

Our teams have a mammoth task ahead of them, but progress has definitely been made.

We'll keep you posted on the progress of the challenge!

Leave a comment